Drawing Number: 21102

Revision: B

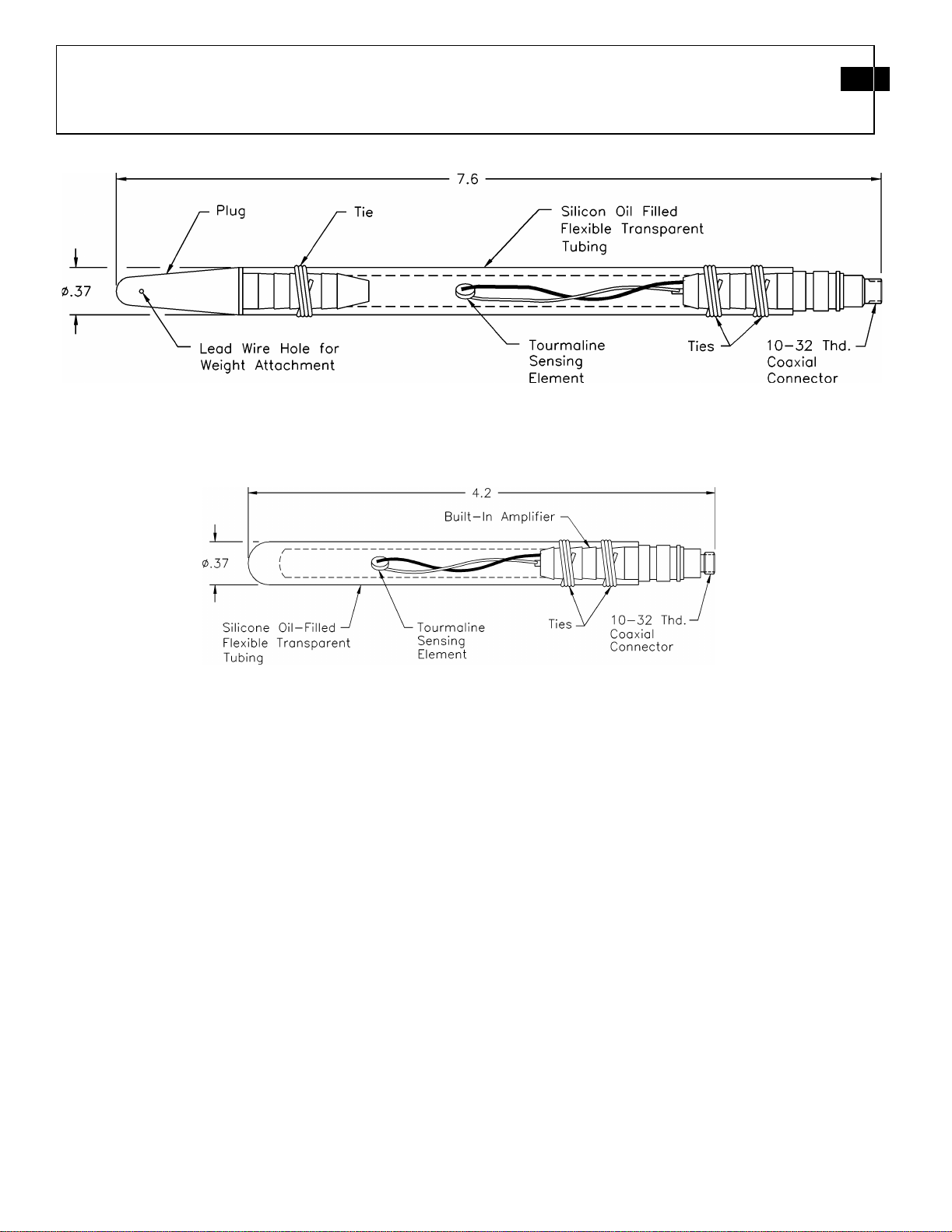

Some models of the Series 138 feature a tygon tube

closed at one end with conical-shaped delrin plug. The

plug features a small hole for attachment of a weight.

Other models feature a one-piece molded closed tube.

2.0 INSTALLATION, CABLE

ATTACHMENT, AND SEALING

THE CABLE/CONNECTOR

ASSEMBLY

Various methods are used to mount the 138 sensors for

use in liquids. Care should be taken to prevent

conductive liquids from entering the cable or

connector assemblies, where they could cause

corrosion, short-circuiting or degradation of

insulation resistance.

For low-pressure (<500psi) dynamic measurements, a

standard low-noise coaxial cable with an extruded

teflon jacket and a 10-32 connector can be used. Heat

shrink tubing, RTV silicon rubber, or sometimes

silicone grease can make an adequate seal in an

environment with low static pressure.

For high static pressures due to deep submersion or use

in a pressure vessel, alternate methods of sealing the

cable/connector may be required. A method of

waterproofing the cable/connector assembly of a 138

which also provides protection to the cable is to put a

flexible tube (plastic, tygon, etc.) around the cable

and cable/connector assembly. Tie the tube at the

metal housing with monofilament or fine steel wire.

The opposite end of the tube must be above the level

of the liquid or sealed around the cable to prevent

liquid from entering the protective tubing. Filling the

protective tube with a non-conducting liquid such as

Dow Coming silicone oil can be done to prevent the

tube from collapsing. This will also equalize pressure

inside and outside the tubing, helping to prevent a

conductive liquid (such as water) from entering.

In some blast applications, when using a standard 10-

32 micro cable/connector, the high shock can flex the

cable/connector joint enough to move the center pin of

the 10-32 cable connector. This can cause noise on

the output signal. Protecting the connection from

shock may be required.

PCB Model 070A03 adaptor can be used to adapt the

10-32 micro jack on the 138 to a BNC jack. A heavier

coaxial cable (eg. RG-58/U) can now be used in place

of the micro cable. Because of the large mass of the

070A03 compared to the 10-32 jack, this connection

should be sealed and protected from shock and

turbulence. Putting a two to three inch diameter of duct

seal, wrapped with a waterprooftape, will seal the

connection and provide shock protection at the

cable/connector/ amplifier assembly.

PCB Model 070A09 Solder Connector Adaptor can

also be used to attach a short length (~two to three

inches) of ribbon cable to a 138. The ribbon cable can

then be soldered to an extension cable. The ribbon

cable and both solder connections should be sealed

with a suitable waterproofing material. Various types

of sealing materials such as polyethylene and flexane

have been shown to be effective for sealing cables,

connectors, etc.

2.1 MOUNTING OR SUSPENDING

THE SENSOR

After the cable/connector assembly is sealed, the

sensor can be suspended in the liquid where the

measurement is to take place. For low dynamic

pressure measurements (less than 500 psi), models

featuring a small hole in the conical end piece of the

tube allow attachment of a light weight (~two lb.) to

suspend the sensor in a vertical position.

The line should be of light material (monofilament,15

lb. test) to enable it to break easily. This way, the

sensor does not pull apart in the turbulence caused by

the collapse of gas bubbles resulting from a shock

wave.

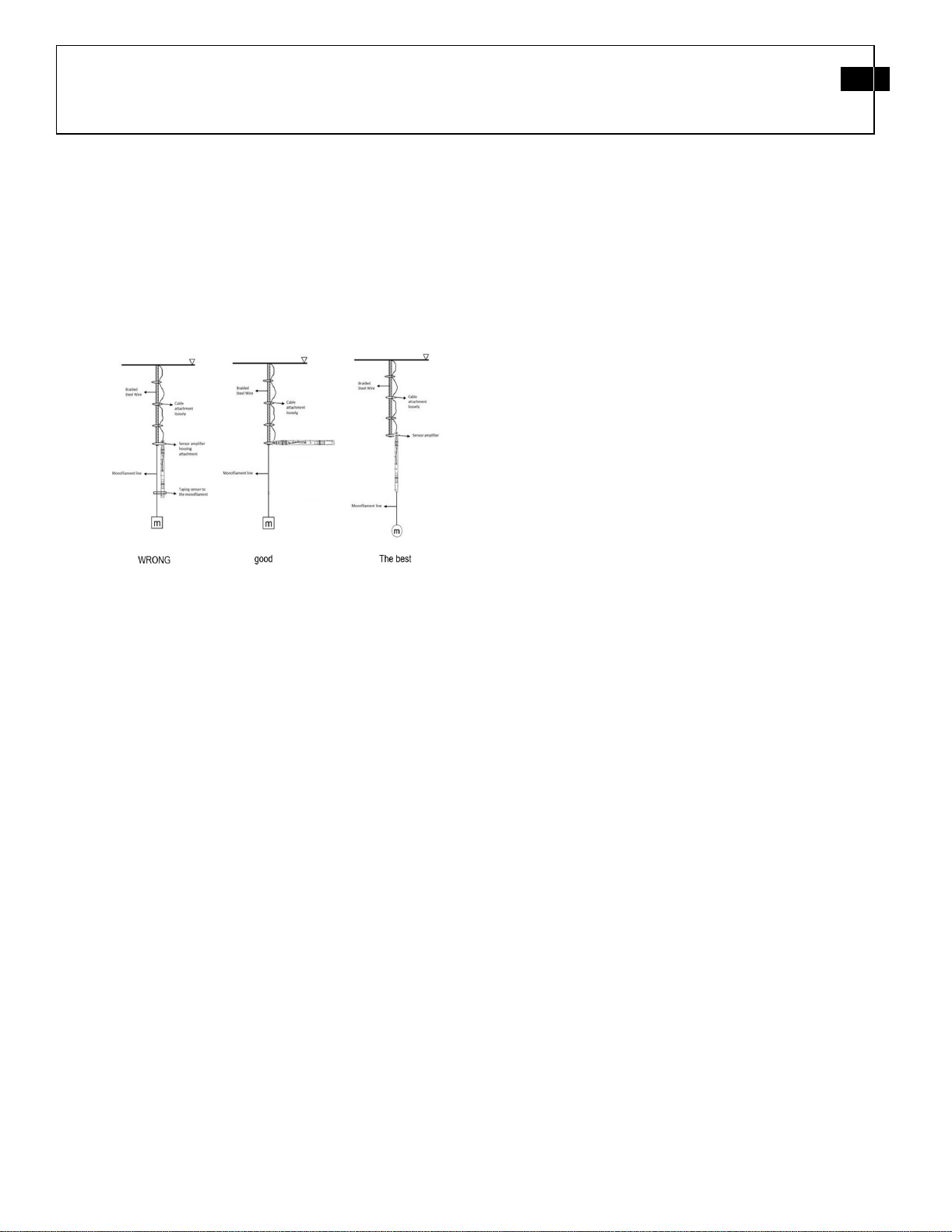

For higher pressure dynamic measurements, alternate

methods of suspending the sensor should be used to

minimize damage from turbulence. Taping or

attaching (with cable ties) the sensor amplifier housing

to a braided steel wire is a method that is suited for use

in higher dynamic pressure measurements.