PDi WaveStar Manual instruction

WaveStar®

Color Monitor

Setup and Operation

Ctrl Nr: PM375103

Revision: 003

WaveStar Color Monitor ___________________________________________________________

Ctrl Nr: PM375103 Revision: 003 2

Thank you for your recent purchase of a WaveStar®Color Monitor from Power Distribution, Inc.

For safety reasons as well as to ensure optimal performance of your WaveStar®Color Monitor, please

carefully read the instructions before trying to install, operate, service or maintain the system.

For any questions regarding the installation, operation, service or maintenance of your WaveStar®

Color Monitor, please contact us:

Power Distribution, Inc. | 4200 Oakleys Court | Richmond, VA 23223

+1 804 737 9880 | +1.800.225.4838

pdicorp.com | service@pdicorp.com

WaveStar® Color Monitor

Setup and Operation

Ctrl Nr: PM375103 Revision: 003

Release Date: December 2017

© 2017 by Power Distribution, Inc. All rights reserved.

Cover Photo: WaveStar® Color Monitor Home Screen

PDI, JCOMM, Quad-Wye, ToughRail Technology, and WaveStar are registered trademarks of Power

Distribution Inc. All other trademarks are held by their respective owners.

Power Distribution, Inc. (PDI)

Power Distribution, Inc. (PDI) designs, manufactures, and services mission critical power distribution, static switches, and

power monitoring equipment for corporate data centers, alternative energy, industrial and commercial customers around the

world. For over 30 years, PDI has served the data center and alternative energy markets providing flexible solutions with the

widest range of products in the industry.

.

Contents________________________________________________________________________

Ctrl Nr: PM375103 Revision: 003 3

Contents

Safety ............................................................................................6

1Introduction..........................................................................7

1.1 WaveStar Color Monitor Summary....................................................... 7

1.2 Power On and Access......................................................................... 7

1.3 Screen Summary and Navigation ........................................................ 8

1.4 Entering Data ................................................................................... 8

2Color Monitor Networking ...................................................10

2.1 Supported Protocols ........................................................................ 10

2.2 Monitor Network Connections ........................................................... 10

2.2.1 Modbus RTU Ports................................................................. 11

2.2.2 Modbus RTU 2-Wire vs. 4-Wire Configuration ........................... 11

2.3 Modbus RTU Cables ......................................................................... 12

2.3.1 Cable Specification................................................................ 12

2.3.2 Cable Biasing and Termination................................................ 12

2.4 Ethernet Cables .............................................................................. 12

2.5 Customer Modbus RTU Connections ................................................... 12

2.5.1 Power Distribution Unit (PDU)................................................. 13

2.5.1 Remote Power Panel (RPP)..................................................... 14

2.5.1 JCOMM ................................................................................ 14

2.6 Modbus Addressing ......................................................................... 15

2.7 Communicating with the Monitor: Commands and Replies .................... 16

2.7.1 Modbus Commands and Replies.............................................. 16

2.7.2 Limit on Open Sockets........................................................... 16

2.7.3 SNMP Commands.................................................................. 16

3Setup: Monitor and Network ...............................................17

3.1 SETUP: Miscellaneous Parameters ..................................................... 17

3.2 Network Setup................................................................................ 18

3.2.1 Downstream Modbus Device Chain Setup................................. 18

3.2.2 Modbus RTU Setup................................................................ 18

3.2.3 TCP/IP and Modbus TCP/IP Setup ........................................... 19

3.2.4 SNMP Setup ......................................................................... 19

3.2.5 Loading INI Parameters from an SD Card................................. 20

3.3 Software Versions ........................................................................... 20

4Device Chain: Settings ........................................................22

4.1 Initial Device Chain ......................................................................... 22

4.2 Device Settings............................................................................... 23

WaveStar Color Monitor ___________________________________________________________

Ctrl Nr: PM375103 Revision: 003 4

4.2.1 PDU Device Settings.............................................................. 23

4.2.2 Enhanced Subfeeds Settings .................................................. 24

4.2.3 BCMS Normal and KWH Settings............................................. 24

4.2.4 BCMS CB Subfeeds Settings ................................................... 25

4.2.5 BCMS IEC Settings................................................................ 26

5Device Chain: Readings .......................................................27

5.1 PDU Device Readings....................................................................... 27

5.2 Enhanced Subfeeds (ESF) Readings................................................... 28

5.3 BCMS (Normal) Panelboard Readings................................................. 30

5.4 BCMS KWH Readings ....................................................................... 31

5.5 BCMS CB (Subfeeds) Readings.......................................................... 33

5.6 BCMS IEC Readings ......................................................................... 33

6Alarms and Troubleshooting ...............................................35

6.1 Summary Alarm Indicators ............................................................... 35

6.2 Alarm Screen and Alarm List............................................................. 35

6.3 Alarms by Device Type..................................................................... 37

6.3.1 Color Monitor Alarms............................................................. 37

6.3.2 PDU Alarms.......................................................................... 37

6.3.3 Enhanced Subfeeds ............................................................... 39

6.3.4 BCMS Panelboard—Typical Alarms .......................................... 40

6.4 Troubleshooting .............................................................................. 40

7Web Pages ..........................................................................42

Glossary ......................................................................................46

Bibliography ................................................................................47

Appendix: Color Monitor Backpanel .............................................48

Tables

Table 1 Pin-Out for Modbus Headers ...................................................................................................11

Figures

Figure 1 WaveStar Color Monitor Installed in a JCOMM........................................................................7

Figure 2 HOME Screen and Navigation Buttons ....................................................................................8

Figure 3 Entering Alphanumeric Data.....................................................................................................9

Figure 4 Color Monitor Network Connections.......................................................................................10

Figure 5 Color Monitor 4-wire Modbus Connections ............................................................................12

Figure 6 Modbus RTU Connections: PDU Basic Contractor Board .....................................................13

Figure 7 Modbus RTU Connections: PDU Enhanced Contractor Board..............................................13

Figure 8 Modbus RTU Customer Connection: RPP Upstream.............................................................14

Contents________________________________________________________________________

Ctrl Nr: PM375103 Revision: 003 5

Figure 9 JCOMM Modbus Connections................................................................................................14

Figure 10 Modbus Addressing..............................................................................................................15

Figure 11 SETUP Screen......................................................................................................................17

Figure 12 Calibrating the Touchscreen.................................................................................................17

Figure 13 Modbus RTU Setup ..............................................................................................................18

Figure 14 Modbus TCP/IP and SNMP Setup........................................................................................19

Figure 15 Model Information.................................................................................................................20

Figure 16 Initial Device List...................................................................................................................22

Figure 17 Settings: PDU Device ...........................................................................................................23

Figure 18 Settings: Enhanced Subfeeds (ESF)....................................................................................24

Figure 19 Settings: BCMS Device ........................................................................................................25

Figure 20 Settings: BCMS Subfeeds ....................................................................................................25

Figure 21 Settings: BCMS IEC .............................................................................................................26

Figure 22 Readings: PDU.....................................................................................................................27

Figure 23 Readings: Enhanced Subfeeds (ESF) (Part 1).....................................................................28

Figure 24 Readings: Enhanced Subfeeds (ESF) (Part 2).....................................................................29

Figure 25 Readings: BCMS (Normal) ...................................................................................................30

Figure 26 Readings: BCMS KWH (Part 1)............................................................................................31

Figure 27 Readings: BCMS KWH (Part 2)............................................................................................32

Figure 28 Readings: BCMS CB (Two Subfeeds)..................................................................................33

Figure 29 Readings: BCMS IEC Panelboard........................................................................................34

Figure 30 Alarm and Warning Summary Status Icons..........................................................................35

Figure 31 ALARM Screen with an Alarm List........................................................................................36

Figure 32 Find the Circuits in an Alarm Condition ................................................................................36

Figure 33 Web Pages: Home Page ......................................................................................................42

Figure 34 Web Pages: Device Chain....................................................................................................42

Figure 35 Web Pages: Display Device .................................................................................................43

Figure 36 Web Pages: PDU Board.......................................................................................................44

Figure 37 Web Pages: Enhanced Subfeeds.........................................................................................45

Figure 38 Color Monitor Backpanel ......................................................................................................48

Safety __________________________________________________________________________

Ctrl Nr: PM375103 Revision: 003 6

Safety

Please pay special attention to the use of “Danger” symbols throughout this manual indicating

electrical or other safety hazards. Following these safety instructions is extremely important to avoid

possible injury or death.

Follow safe electrical work practices:

•Read, understand, and follow the instructions before installing this product.

•Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel and in accordance with all local safety codes. Power Distribution,

Inc. assumes no responsibility for any consequences arising out of the use of this

manual. This document should not be viewed as sufficient by otherwise non-qualified

personnel to operate, service, or maintain the equipment discussed.

•Disconnect and lock-out all power supplying equipment before working on or

installing WaveStar®Color Monitor components. Use a properly rated voltage sensing

device to confirm power is OFF.

•Install device in an appropriate electrical enclosure per local regulations.

•ESD sensitive equipment. Ground yourself, discharge any static charge and ensure

that the device is effectively grounded before handling the unit.

The WaveStar®Color Monitor must be installed by licensed electricians or

by PDI-authorized technicians.

DANGER!

Severe or fatal injury can result from electrical shock during contact with high

voltage conductors, monitoring PCBs, or similar equipment.

Disconnect power before drilling holes, attaching conduit, and attaching WaveStar®

Color Monitors to PDUs, RPPs, or other power distribution equipment.

Use Lock Out/Tag Out procedures.

Wear suitable personal protective clothing and use protective equipment for

performing mechanical and electrical installations.

Leave ample space for attaching and routing wires.

Introduction_______________________________________________________________________

Ctrl Nr: PM375103 Revision: 003 7

1Introduction

1.1 WaveStar Color Monitor Summary

The WaveStar®Color Monitor is a 7-inch color touchscreen which displays power management

information for up to twenty (20) Branch Circuit Monitoring System (BCMS) devices and other PDI

devices in the Monitor’s downstream Modbus network.

The Color Monitor is incorporated into PDI products, such as PDUs, RPPs, or JCOMM®s, and can

also function as a stand-alone power monitoring station.

Figure 1 shows the Monitor used in a JCOMM®.

Figure 1 WaveStar Color Monitor Installed in a JCOMM

1.2 Power On and Access

The Color Monitor does not have an on/off switch. The Monitor automatically powers-on whenever

power is applied to the unit in which it is installed.

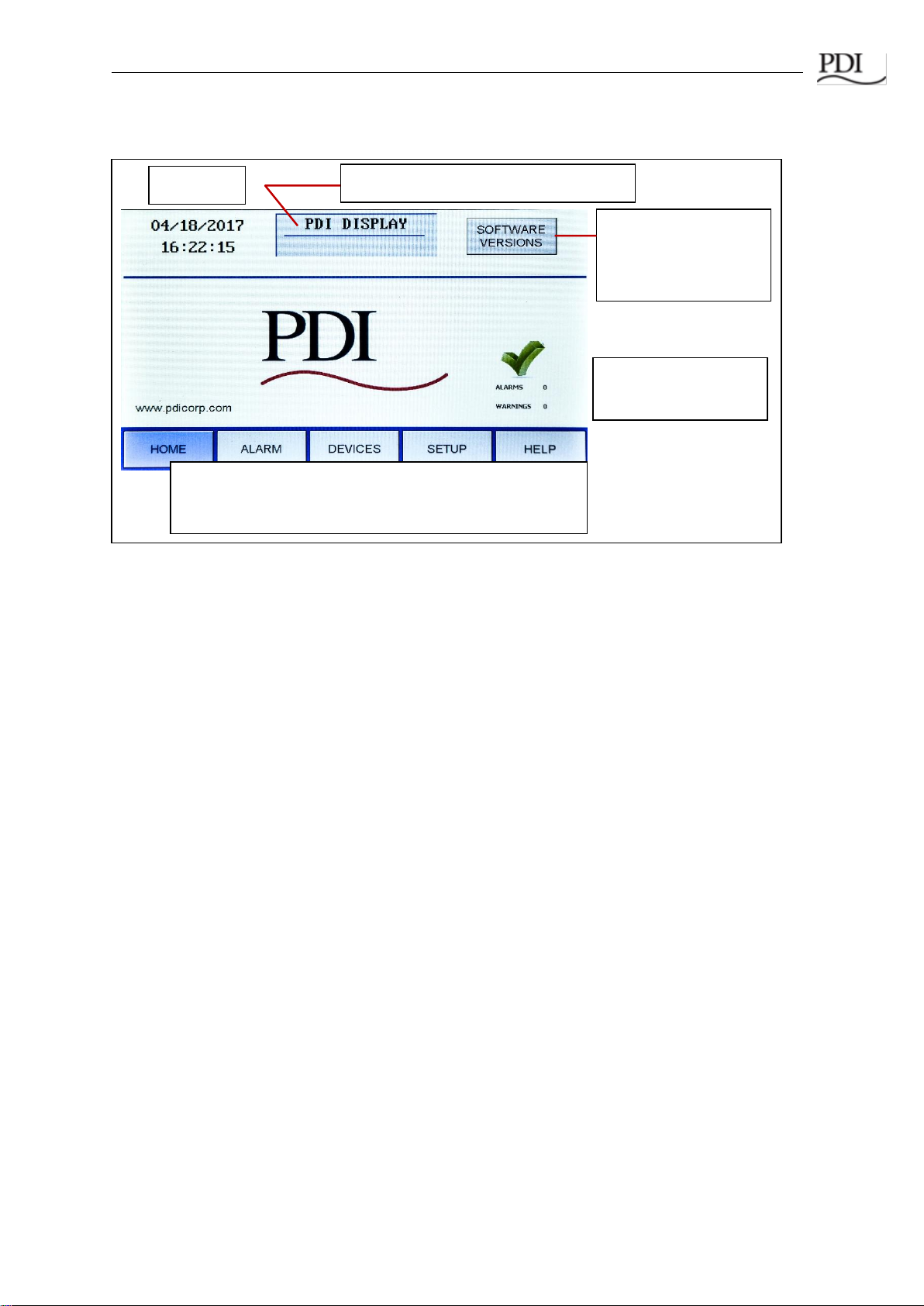

When the unit is powered on for the first time, the Home Screen appears (Figure 2).

The Color Monitor is accessed by touching the screen. If the unit is powered up and is not touched for

15 minutes, the backlight will turn off to save power. The backlight turns back on when the operator

again touches the screen, showing the last displayed screen.

WaveStar Color Monitor_____________________________________________________________

Ctrl Nr: PM375103 Revision: 003 8

1.3 Screen Summary and Navigation

Setup and configuration information for the Color Monitor are on these screens:

•SETUP: system parameters, such as number of devices in Monitor’s chain

•Device SETTINGS: Device-specific parameters, such as user-specified device name

(DEVICES Device Name SETTINGS)

•SOFTWARE VERSIONS: a list of software versions for each device, accessible only from

the HOME screen.

•DEVICES screen gives a list of all devices in the Monitor’s chain.

•Device SETTINGS screen lets you set device name and parameters specific to the

device.

Setpoints in the device’s points list, such as breaker alarm thresholds, are not viewable or modifiable

on the Monitor.

Power monitoring information as it is stored in each device’s points list (or Modbus register map) is in

each DEVICE READINGS screen.

Alarms and warnings are displayed on these screens:

•ALARM: List of all extant warnings and alarms by device name

•All screens: Warning and alarm summary counts

HELP screen contains Modbus information.

1.4 Entering Data

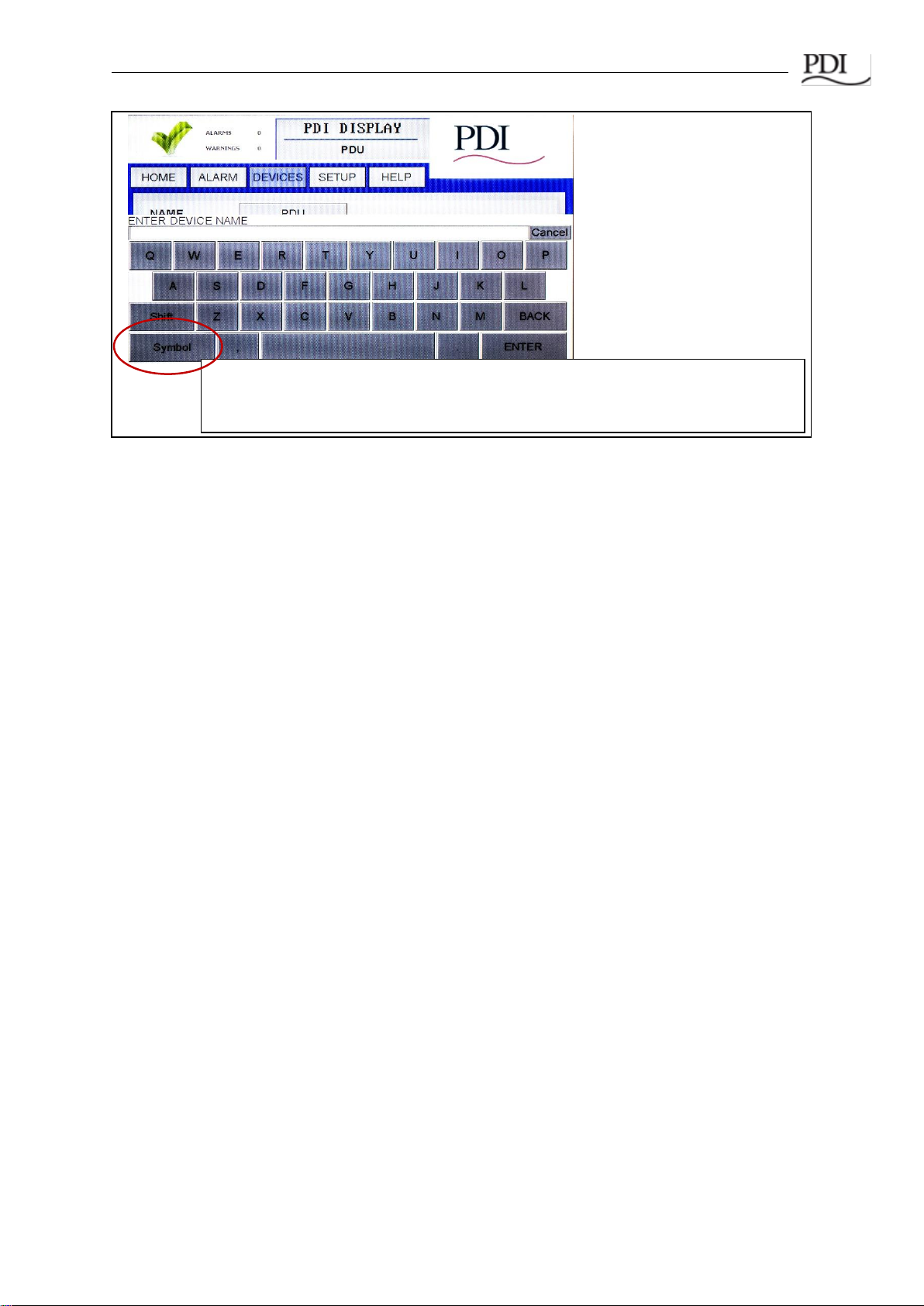

When you touch a field that requires alphanumeric data, such as device names, passwords, or

version numbers, a touchscreen keyboard will appear, prompting you for information based on

context. You can toggle between LETTERS and SYMBOLS keyboards, for entering text or numbers

(Figure 3).

•The main navigation buttons are present on each screen.

•Touch a button to select that screen.

•

Button turns blue when selected.

Banner, user-specified on SETUP screen

SOFTWARE

VERSIONS button is

only displayed on the

HOME

screen.

Date/Time

Alarm summaries are

given on each page.

Figure 2 HOME Screen and Navigation Buttons

Introduction_____________________________________________________________________

Ctrl Nr: PM375103 Revision: 003 9

Touch here to toggle between Symbol and Letters keyboards as you enter model

information.

Touch

ENTER

to complete the operation. Touch

Cancel

to terminate the operation.

Figure 3 Entering Alphanumeric Data

WaveStar Color Monitor_____________________________________________________________

Ctrl Nr: PM375103 Revision: 003 10

2Color Monitor Networking

2.1 Supported Protocols

All protocols supported by the Color Monitor can be used simultaneously.

Downstream Protocol The downstream device network has fixed parameters of Modbus RTU, 9600

baud, EVEN parity.

Upstream Protocols There are separate upstream ports for Modbus RTU and Ethernet, supporting

these protocols:

•Modbus RTU

•Ethernet port

•TCP/IP, used by the web page server (see Chapter 7, Web Pages)

•Modbus TCP/IP

•SNMP Version 1

2.2 Monitor Network Connections

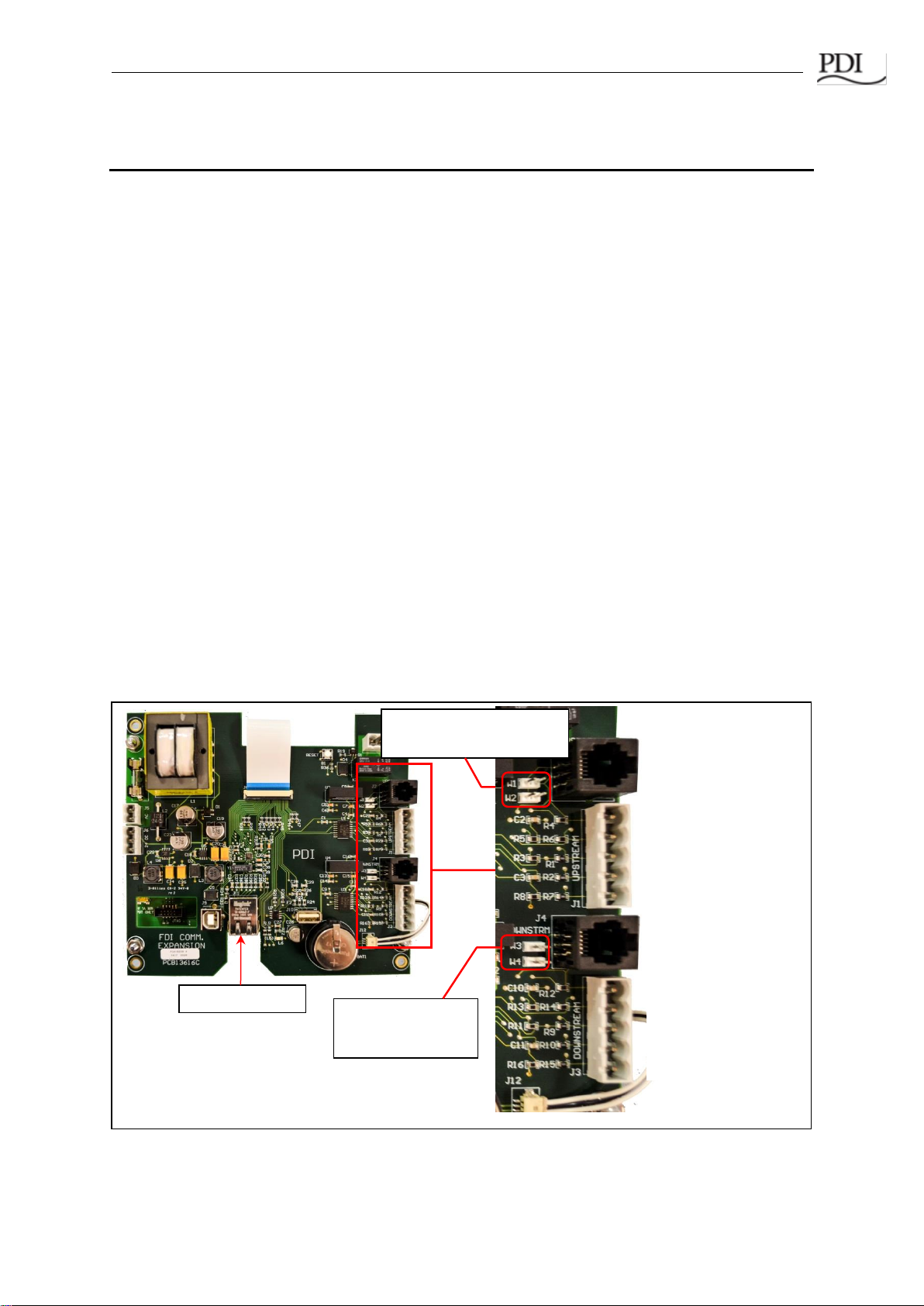

The Color Monitor’s backpanel has Modbus RTU and Ethernet ports (Figure 4).

For Color Monitors embedded in PDI products (PDUs, RPPs, or JCOMMs), Modbus RTU backpanel

connections are typically made in manufacturing and extended to a terminal block or external panel

for convenient customer access. See 2.5 Customer Modbus RTU Connections.

The customer’s Ethernet cable is connected directly to the Monitor’s Ethernet port.

J2: Modbus RTU

Upstream

RJ12 Connection

(to PDU M4G Board)

J4: Modbus RTU

Downstream

RJ12 Connection

(to PDU M4G Board)

J1: Modbus RTU

Upstream

Connection (except

PDU M4G Board)

J3: Modbus RTU

Downstream

Connection (except

PDU M4G Board)

Ethernet Port

Jumper W1, W2 for

2-wire Modbus upstream

Jumper W3, W4 for

2-wire Modbus

downstream

Figure 4 Color Monitor Network Connections

Color Monitor Networking________________________________________________________

Ctrl Nr: PM375103 Revision: 003 11

2.2.1 Modbus RTU Ports

The Color Monitor has four (4) paralleled Modbus ports:

•J1 and J3 are header/plug connections for connecting to most devices.

oJ1 is the upstream port.

oJ3 is the downstream port.

•J2 and J4 accept standard RJ12 phone cable plugs for connection to an M4G PDU

board.

oJ2 is the upstream port.

oJ4 is the downstream port.

The Modbus RTU interface is isolated, and pin designations are given in Table 1:

Pin

J1, J3

J2 (for RJ12 plugs)

J4 (for RJ12 plugs)

1

Ground

Not used

Not used

2

RX-

RX-

TX-

3

RX+

TX-

RX-

4

TX-

RX+

TX+

5

TX+

TX+

RX+

6

NA

Ground

Ground

Table 1 Pin-Out for Modbus Headers

2.2.2 Modbus RTU 2-Wire vs. 4-Wire Configuration

PDI devices have two (2) jumpers near their Modbus ports for configuring 2-wire vs. 4-wire Modbus

RTU (see Figure 4). The Monitor’s 2-wire configuration jumpers are W1 and W2 (upstream) and W3

and W4 (downstream). Upstream and downstream chains can be differently configured.

For 2-wire configuration:

•At least one device in a device chain must have both jumpers jumped on its Modbus

connection. If any device in the chain has jumpers installed for 2-wire, all of the device

chain is 2-wire. To avoid confusion when troubleshooting, all of the devices in the chain

should be jumped in the same way.

•TX+ or RX+ on the Monitor (either one, because the on-board 2-wire jumpers short them

together) wires to TX+ or RX+ on downstream devices.

•TX- or RX- on the Monitor wires to TX- or RX- on downstream devices.

•The + and - signal wires should comprise of a (twisted) wire pair residing in the same

shield.

For 4-wire configuration:

•All of these jumpers must be removed from every device in the chain.

•TX+ on the Monitor’s PCB or on the customer Building Management System (BMS) wires

to RX+ on a device PCB (see Figure 5).

•TX- from the Monitor or BMS wires to RX- on device PCB (see Figure 5).

•A second pair of wires connects the other pair of TX+ / RX+ & TX- / RX-.

•The TX+ & TX- going to the RX+ & RX- should be in the same shield. Do not run the +'s

in one shield and the -'s in another. Doing so may lead to sporadic communication.

WaveStar Color Monitor_____________________________________________________________

Ctrl Nr: PM375103 Revision: 003 12

•Run a dedicated ground wire with the signal wires and only ground the shield at one end.

2.3 Modbus RTU Cables

2.3.1 Cable Specification

RS485/RS422 cable length can be up to 4000 ft. if you use the proper cable:

•The cable resistance should be ≤ 27 ohms/1000ft @ 1 kHz and the mutual capacitance

should be ≤ 14pf/ft @ 1 kHz.

•4-wire cabling:

oRS422 is typically 4-wire.

oUse a shielded cable with two (2) twisted pairs and a shield/ground wire.

oThe two transmit lines must be in one twisted pair and the two receive lines in the

other twisted pair.

•2-wire cabling:

oRS485 is typically 2-wire and is slower than RS422.

oUse a shielded cable with one (1) twisted pair and a shield/ground wire.

2.3.2 Cable Biasing and Termination

PDI devices have soft biasing (27K pull-up and pull-down resistors) on the + and –transmit and

receive lines. Therefore, if the customer’s Master device allows for control, PDI recommends that the

user turn on biasing and turn off termination, which may “fight” the biasing. Biasing the Master

device’s lines is not critical because the Color Monitor is already biasing the lines. If termination is

needed because of an extremely long cable run, PDI recommends that a small capacitor be put in

series with the terminating resistor.

2.4 Ethernet Cables

The maximum length of Ethernet cable depends upon the customer’s choice of Ethernet cable.

2.5 Customer Modbus RTU Connections

When a Color Monitor is embedded in a PDI product (PDU, RPP, or JCOMM), the customer does not

typically wire Modbus RTU directly to the Monitor. Downstream Modbus RTU links are typically to

internal devices and are wired at the factory. The upstream Modbus RTU link is extended from the

Monitor to a customer connection port, which differs by unit.

Color

Monitor

or BMS

Devices 2/3

BCMS PCB

Subfeeds

Devices 4/5

BCMS

Panelboards

Device 1

PDU Board

RX+ TX+ TX+ TX+

RX-TX-TX-TX-

TX+ RX+ RX+ RX+

TX-RX-RX-RX-

Figure 5 Color Monitor 4-wire Modbus Connections

Color Monitor Networking________________________________________________________

Ctrl Nr: PM375103 Revision: 003 13

2.5.1 Power Distribution Unit (PDU)

On PDI PDUs, customers make Modbus RTU connections to the PDU’s Contractor Board. Basic and

Enhanced Contractor Boards are shown (Figures 6, 7).

Modbus RTU Upstream:

paralleled connectors

Modbus RTU Downstream:

usually wired at factory.

Modbus RTU

Upstream

Connection

Modbus RTU Downstream Connection to

internal PDU devices (usually wired at

factory).

Figure 6 Modbus RTU Connections: PDU Basic Contractor Board

Figure 7 Modbus RTU Connections: PDU Enhanced Contractor Board

WaveStar Color Monitor_____________________________________________________________

Ctrl Nr: PM375103 Revision: 003 14

2.5.1 Remote Power Panel (RPP)

2.5.1 JCOMM

When a JCOMM has a Color Monitor, the customer Modbus RTU connections are made to the

JCOMM Connections Panel on the left inside of the unit.

Figure 9 JCOMM Modbus Connections

On PDI RPPs the Color

Monitor upstream

Modbus connection is

brought to a terminal

block for convenient

customer connection.

Downstream connections

are internal to the RPP

and are wired at the

factory.

Internal Label shows

Modbus RTU wiring.

TX+

TX-

RX+

RX-

Common

JCOMM Connections

Panel

(Left Side of JCOMM)

Modbus Out

Connector

Modbus In

Connector

TX+

TX-

RX+

RX-

Common

Modbus Plug

Wiring 4-Wire

Modbus Plug

Wiring 2-Wire with

2-Wire Jumpers

Figure 8 Modbus RTU Customer Connection: RPP Upstream

Color Monitor Networking________________________________________________________

Ctrl Nr: PM375103 Revision: 003 15

2.6 Modbus Addressing

Refer to Figure 10, “Modbus Addressing,” with the following bullet points:

•The Monitor is a Modbus master to its downstream devices. The upstream Modbus

master cannot directly address these devices, but rather addresses them through the

Monitor. Upstream and downstream are separate Modbus segments.

•The Monitor’s upstream address can be set to from 1 to 255, but you must leave enough

addressing capacity for downstream devices. The monitor will not respond to a command

sent to address 0. The address is set in Monitor Setup. See Section 3.2.3 “TCP/IP and

Modbus TCP/IP Setup.”

•The Monitor’s downstream devices must be assigned consecutive addresses starting at

address 1.

•For upstream addressing these device addresses are remapped as successor addresses

to the Monitor. If the Monitor has upstream address 30, the downstream addresses 1, 2,

3, 4 are remapped to 31, 32, 33, 34 as seen from the BMS or other Modbus Master.

•Modbus addressing is the same for Modbus RTU and Modbus TCP/IP.

1 2 3 4

Downstream Modbus addresses must be

assigned sequentially from 1.

31 32 33 34

Downstream Modbus addresses are adjusted by

the Monitor’s upstream address.

BCMS

BCMS

PB1 PB2 PB3 PB4

RPP

Figure 10 Modbus Addressing

30

30

30 = Monitor’s assigned upstream

address.

These addresses are visible from

the upstream Modbus master:

To upstream

Modbus

master (BMS,

DCIM, etc.)

Monitor’s Upstream Modbus Segment

Monitor’s Downstream Modbus Segment

WaveStar Color Monitor_____________________________________________________________

Ctrl Nr: PM375103 Revision: 003 16

2.7 Communicating with the Monitor: Commands and Replies

2.7.1 Modbus Commands and Replies

Upstream Modbus on the Color Monitor supports three (3) Modbus commands only (with typical flag

and data values shown in hexadecimal) for communicating with the points lists of the Monitor or

devices in its chain:

1) Read Slave ID (command 11)

Sent Hex: 01 11 C0 2C

Reply Hex: 01 11 0D EA FE 52 50 50 20 44 69 73 70 6C 61 79 A3 A6

2) Read Multiple Holding Registers (command 3)

Sent Hex: 01 03 00 00 00 01 84 0A

Reply Hex: 01 03 02 00 00 B8 44

3) Write to a Single Register (command 6)

Sent Hex: 01 06 00 00 00 00 89 CA

Reply Hex: 01 06 00 00 00 00 89 CA

It is important to carefully verify early in system bring-up that the registers you are addressing are the

correct ones. In a points list or Modbus register map, the first analog channel is numbered 1 but is

accessed in software with an index value of 0. Consequently, it is common for a system to be one

register off. Because adjacent registers often have similar readings, being one register off is not

necessarily apparent.

Most analog values are 2-byte integers representing a measured parameter such as input voltage or

current. KWH uses two (2) adjacent 2-byte integers. Some parameters require scaling and are so

noted in the points list.

2.7.2 Limit on Open Sockets

When using Modbus TCP/IP, the Color Monitor can have at most five (5) sockets open at any one

time.

2.7.3 SNMP Commands

Only SNMP version 1 is supported.

The following commands are supported and are typical for the product:

•snmpget

•snmpgetnext

•snmpset

See the MIB file for specifics. The MIB can be downloaded from the PDI website. Reference the

Bibliography in this manual.

Color Monitor Networking________________________________________________________

Ctrl Nr: PM375103 Revision: 003 17

3Setup: Monitor and Network

You set configuration parameters and other information for the Color Monitor in three ways:

•The SETUP screen has system parameters, such as banner name, password, and

network addresses.

•Device SETTINGS screens let you set device names, specific device configurations, and

software versions for each BCMS device in the Monitor’s chain. (See Chapter 4, Device

Chain: Settings.)

•The SOFTWARE VERSIONS screen lets you add the model information for the unit

mounting the Color Monitor.

3.1 SETUP: Miscellaneous Parameters

Touch SETUP to display buttons for several configuration items (Figure 11).

A password is required to access and change setup parameters. Enter the password (default is

“PDI”). The user can navigate through any of the screens and come back to SETUP without having to

re-enter the password for 10 minutes. Touch PASSWORD to change to a new password.

Touch buttons in the initial SETUP

screen to link to miscellaneous setup

functions:

PASSWORD: Keyboard appears, enter

password, then type new password.

HORN DISABLED: Toggle Monitor’s

audible alarm to ENABLED/DISABLED.

BANNER: Banner setup (here shown

as “PDI DISPLAY”) is on same screen

as Modbus setup (Figure 7).

TIME & DATE: Set time and date; used

on HOME screen and alarm

timestamps.

CALIBRATE GUI: See next figure.

See 3.2 Network Setup.

CALIBRATE GUI: Color Monitors

are calibrated at the factory and

should not need calibration in the

field. However, if necessary, touch

CALIBRATE GUI and follow on-

screen instructions, as shown at

left.

Figure 11 SETUP Screen

Figure 12 Calibrating the Touchscreen

WaveStar Color Monitor_____________________________________________________________

Ctrl Nr: PM375103 Revision: 003 18

3.2 Network Setup

Note: Improper configuration of a WaveStar Color Monitor may conflict with other monitors or

devices on the network.

3.2.1 Downstream Modbus Device Chain Setup

To set Modbus device chain parameters, touch DEVICES/MODBUS (Figure 13):

•Number of Devices should equal the number of devices in the Monitor’s device chain.

Up to twenty (20) devices are allowed. The Monitor uses this number to determine how

many devices to search for in its downstream chain.

•When you add new devices, increment this counter, then press “ENTER”. The Monitor

will automatically start a new search and find all of the downstream devices. The devices

will then be listed in the DEVICES Screen, where the added devices will initially show up

as generic device names.

•For each new device the user should then enter a unique device name. Unique device

names are needed to isolate alarms and measurements to specific devices.

3.2.2 Modbus RTU Setup

Downstream Modbus settings cannot be changed.

Upstream Modbus provides network characteristics on the upstream side of the Monitor.

•Address is the address that the upstream Modbus master, such as the Building

Management System (BMS), uses to address the Monitor. The downstream device

addresses are incremented sequentially from this address. So if the Monitor has address

20, the next three devices will appear 21, 22, and 23 to the upstream master device. (See

Figure 9, “Modbus Addressing”.)

Modbus Device Chain:

Banner Name displayed on top line.

Number of Devices should equal

number of devices connected in

Monitor’s downstream device chain.

Upstream Modbus:

Address of Monitor on upstream side

Baud rate (9600/19200/38400)

Parity (even/odd/none)

Downstream Modbus Network

characteristics are fixed and cannot

currently be modified.

On SETUP screen, touch DEVICES/MODBUS.

The DEVICES/MODBUS screen defines the Modbus

network and device chain as well as set the banner

name for the header.

Figure 13 Modbus RTU Setup

Color Monitor Networking________________________________________________________

Ctrl Nr: PM375103 Revision: 003 19

•Upstream Modbus settings for Baud rate and Parity must match those for the upstream

Modbus master.

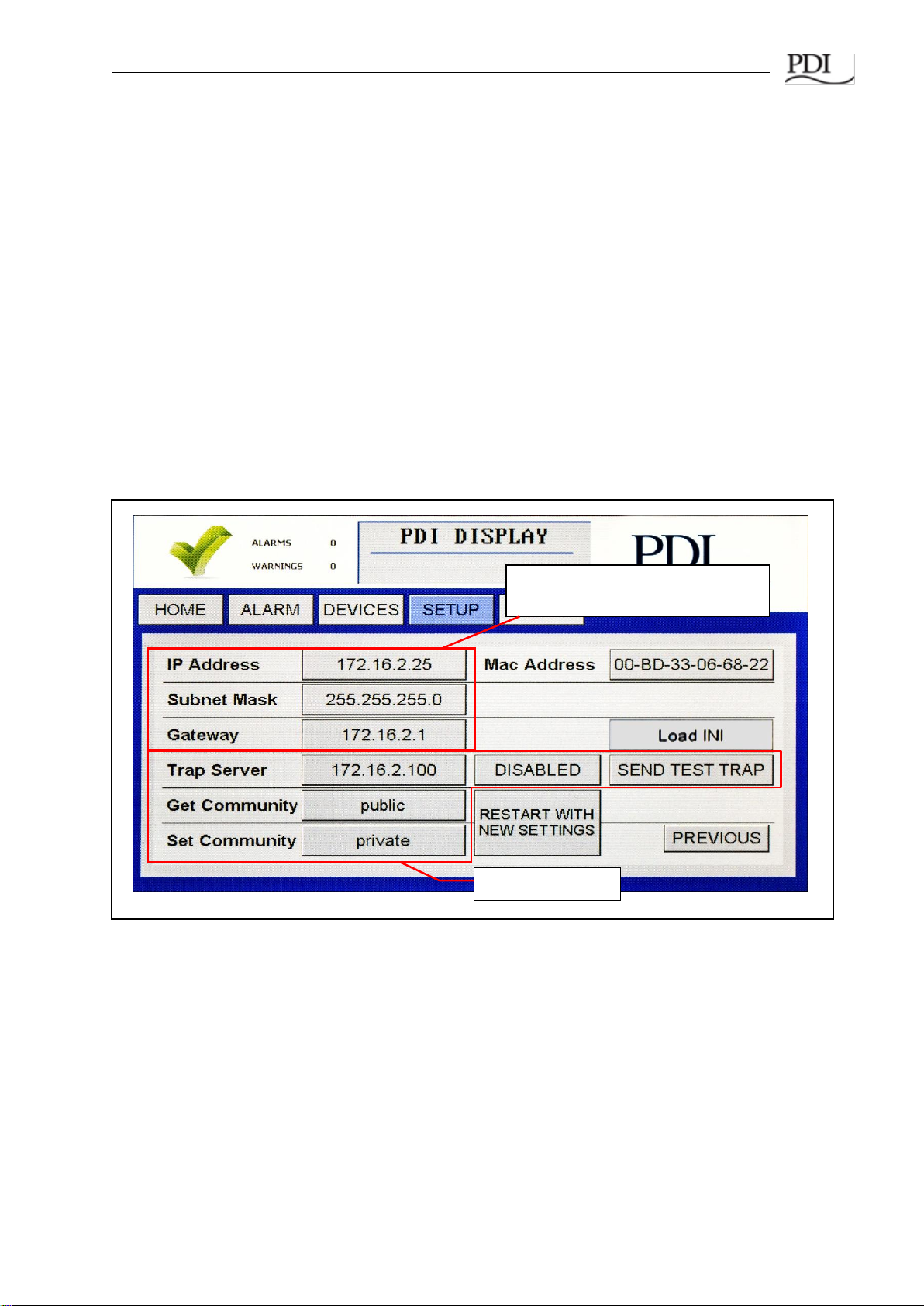

3.2.3 TCP/IP and Modbus TCP/IP Setup

For TCP/IP, the customer must provide an Ethernet cable connected to the Ethernet port (RJ45

header J11) on the Monitor. (See Figure 4, “Color Monitor Network Connections”.)

On the SETUP screen, touch NETWORK/SNMP to display the network parameters for TCP/IP

(Figures 11, 14)).

The following must be specified for Modbus TCP/IP:

oIP Address

oSubnet Mask

oGateway

Each connected monitor must be assigned a unique address. DHCP is not supported.

Touch RESTART WITH NEW SETTINGS if any parameter is changed on this screen. The processor

will reboot and search the network for connections.

Figure 14 Modbus TCP/IP and SNMP Setup

3.2.4 SNMP Setup

To use SNMP, the customer must connect an Ethernet link to the RJ45 header J11 (see Figure 4) on

the Monitor using a standard Ethernet cable.

For SNMP setup, on the SETUP screen, touch NETWORK/SNMP to display the network parameters

for SNMP (Figures 11, 14).

In addition to the TCP/IP specification, the following must be specified for SNMP:

•Specify the Trap Server IP address

•Toggle ENABLED/DISABLED for the trap server.

TCP/IP Setup: Set for TCP/IP,

Modbus TCP/IP, and SNMP

Set for SNMP

WaveStar Color Monitor_____________________________________________________________

Ctrl Nr: PM375103 Revision: 003 20

•Touch SEND TEST TRAP to verify operation.

•Get Community security string for Get operations.

•Set Community security string for Set operations.

Touch RESTART WITH NEW SETTINGS if any parameter is changed on this screen. The processor

will reboot and search the network for connections.

3.2.5 Loading INI Parameters from an SD Card

Touching Load INI loads configuration parameters from an SD card inserted into the Monitor. This

function makes it easy to initialize a set of Monitors using common parameters. It is intended for

manufacturing and service use.

3.3 Software Versions

The SOFTWARE VERSIONS list (Figure 15) lists information about software levels for the Monitor

and its device chain and a customer-specified model number for the unit in which the Monitor is

installed, such as a PDU or RPP. The list has no configuration use: it does not have parameters that

determine Monitor operation.

•MODEL number: Touch MODEL and enter model number with the pop-up keyboard.

On HOME screen, touch the SOFTWARE

VERSIONS button to display a scrollable list of

versions levels for the Monitor and devices in its

device chain.

Device version numbers are customer-specifiable

IDs, intended as device software version numbers.

Specify these in the VERSION field of

DEVICESDEVICESETTINGS screen.

(See

Chapter 3, Device Chain: Settings

.)

Color Monitor (Display) software

VERSION number, from onboard

software

MODEL is intended as a customer-

specifiable ID identifying the unit in which

the Monitor is installed, such as “PDU 182”.

Touch MODEL to enter the model number:

A keyboard appears requesting the

password (Enter “VNUP”).

If password is accepted, a second

keyboard appears asking you to enter the

model number.

Figure 15 Model Information

This manual suits for next models

1

Table of contents

Other PDi Monitor manuals