Peak Scientific 1B User manual

Mass Spectrometer

Table

User Manual

2014 © Peak Scientific - Rev 17 – 07/08/14

Model

Peak PN

AB Sciex PN

MS Table 1B

10-9900

5032309

MS Table User Manual

Page 2 2014 © Peak Scientific - Rev. 17 - 07/08/14

Contents

Change History 4

How to use this Manual 4

Introduction 5

Warranties and Liabilities 6

Safety Notices 7

Symbols 7

Safety Notice to Users 7

Declaration of Conformity 8

Environmental Declaration 9

Technical Specification 1B/1N/1N Hi-Flow 10

Environment 10

Inlet Conditions 10

Generator Outlets 10

Electrical Requirements 10

General 11

Technical Specification 2B/2N 11

Environment 11

Inlet Conditions 11

Generator Outlets 11

Electrical Requirements 12

General 12

Unpacking 13

Installation 14

Generator Environment 14

General Dimensions 14

Unit Controls 15

Rear Connections 16

Drain Connection – MS Table–1N/1N Hi-

Flow/2N only 16

MS Table User Manual

Page 3 2014 © Peak Scientific - Rev. 17 - 07/08/14

Water Bottle Mount Installation 17

Infinity 1031 Installation 17

Levelling Feet 18

Electrical Connection 19

Air Connection 19

Fan power LED - 2B/2N Only 20

Safe Operation of Pump Tray 21

Connecting to the Application 22

Tubing Lengths 22

IMPORTANT DOCUMENT

S

23

Normal Operation 24

Relocation of MS Table 24

Service Requirements 25

Service Schedule 25

Service Plans 25

Cleaning 25

Trouble Shooting 26

MS Table User Manual

Page 4 2014 © Peak Scientific - Rev. 17 - 07/08/14

Change History

Rev.

Comment

Name

Date

1 Initial Release Chris Pugh 18/05/07

2 Notes Added for Indoor Use Only and Altitude Tracy Grierson 10/09/07

3 Nemko Comments Added Jack Aitkinson 20/09/07

4 Final Feedback Included Gavin Logan 03/10/07

5 Added Page 22 Showing Explanation of Symbols Jack Aitkinson 23/10/07

6 Updated to New Format Liam Couttie 16/01/12

7

Power Supply Change

Liam Couttie

12/11/12

8 Change to Technical Specification Layout Liam Couttie 12/03/13

9 Technical Specifications Amended Liam Couttie 22/07/13

10 Voltage Amendment Liam Couttie 30/08/13

11 Fuse Characteristics Liam Couttie 06/09/13

12 Voltage Amendment Liam Couttie 24/10/13

13 Added Hi-Flow Information Liam Couttie 25/10/13

14 Content Update Liam Couttie 29/10/13

15 Brand Colour Change and VAVE Updates Liam Couttie 13/02/14

16 Relocation Information Liam Couttie 26/02/14

17

Declaration of Conformity Update

Liam Couttie

07/08/14

How to use this Manual

This manual is intended for end users and has been written so that it can either

be read as a step by step guide to installation and usage or as a reference

document where you can skip to the relevant information.

Users of a hard copy version can refer to the contents page to find the relevant

information. Users of the soft copy version can use the hyperlinks from the

contents page as well as the hyperlinks between sections.

Please review each of the following sections carefully.

Thank you for selecting Peak Scientific to meet your Gas Generation needs, and

should you require any further assistance or support please do not hesitate to

contact Peak Scientific or Peak Partner from which you purchased your

Generator.

MS Table User Manual

Page 5 2014 © Peak Scientific - Rev. 17 - 07/08/14

Introduction

The MS Table 1B/2B and 1N/1N Hi-Flow/2N (with integrated Nitrogen

Generator) is a transportable table designed specifically to locate a Mass

Spectrometer.

On the inside of the table is a sliding tray to support and house the Mass

Spectrometer Vacuum Pumps.

Heat removal from the inside of the table is facilitated by a range of extraction

fans located at the front and rear panels of the unit,

The MS Table 1N/1N Hi-Flow/2N, specifically, also contains an integrated

Nitrogen Generator providing a source of High Purity Nitrogen with two

independent outlets of clean Zero Grade Air.

To ensure this Generator model meets our high expectations with regards to

reliability and performance, we have tested this new model extensively at our

manufacturing plant and with end users around the world to ensure reliability

and longevity of the system.

MS Table User Manual

Page 6 2014 © Peak Scientific - Rev. 17 - 07/08/14

Warranties and Liabilities

1. The Company warrants that it has title to the Goods.

2. Subject to the provisions of this clause the Company warrants that the

Goods shall comply in all material respects with any specification

referred to in the Order Confirmation (as the same may be amended)

and shall, subject thereto, be free from defects in material and

workmanship for the lesser of a period of twelve months from the date

of delivery or thirteen months from the date of dispatch from the

factory.

3. Save as provided in this clause and except where the Goods are sold to

a person dealing as a consumer (within the meaning of the Unfair

Contract Terms Act 1977) all warranties, conditions or other terms

implied by statute or common law are hereby expressly excluded save

to the extent they may not be lawfully excluded. When the Goods are

sold to a consumer within the meaning of the Unfair Contract Terms Act

1977 their statutory rights are not affected by the provisions of this

clause.

4. In the event of the Customer making a claim in respect of any defect in

terms of clause 2 hereof the Customer must.

1. Reasonably satisfy the Company that the Goods have been

properly installed, commissioned, stored, serviced and used and

without prejudice to the generality of the foregoing that any

defect is not the direct or indirect result of lack of repair and/or

servicing, incorrect repair and/or servicing, use of wrong

materials and/or incorrect spare parts

2. Allow the company to inspect the Goods and/or any installation

and any relevant packaging as and when reasonably required by

the Company.

5. Subject to the Company being notified of any defect as is referred to in

sub-clause 2 hereof within a reasonable time of it becoming apparent

and subject always to the terms of sub-clause 4 hereof, the Company

shall, in its option, replace or repair the defective Goods or refund a

proportionate part of the Price. The Company shall have no further

liability to the Customer (save as mentioned in sub-clause 6 hereof).

6. The Company shall be liable to indemnify the Customer in respect of

any claim for death or personal injury to any person in so far as such is

attributable to the negligence or breach of duty of the Company or any

failure by the Company to comply with the provisions of sub-clause 2

hereof.

7. Save as provided in sub-clause 2 hereof the Company shall not be liable

in respect of any claim by the Customer for costs, damages, loss or

expenses (whether direct, indirect, consequential or otherwise) or

indemnity in any respect howsoever arising including, but not by way of

limitation, liability arising in negligence (other than pursuant to clause 6

above) that may be suffered by the Customer or any third party.

MS Table User Manual

Page 7 2014 © Peak Scientific - Rev. 17 - 07/08/14

Safety Notices

Symbols

This manual uses the following symbols to highlight specific areas important to

the safe and proper use of the Generator

Safety Notice to Users

These instructions must be read thoroughly and understood

before installation and operation of your Peak MS Table

Generator. Use of the Generator in a manner not specified by

Peak Scientific MAY impair the SAFETY provided by the

equipment.

When handling, operating or carrying out any maintenance,

personnel must employ safe engineering practices and

observe all relevant local health and safety requirements and

regulations. The attention of UK users is drawn to the Health

and Safety at Work Act 1974, and the Institute of Electrical

Engineers regulations.

A WARNING notice denotes a hazard. It calls attention to an operating procedure,

process or similar, which if not correctly performed or adhered to, could cause personal

injury or in the worst case death. Do not proceed beyond a WARNING notice until the

indicated conditions are fully understood or met.

A CAUTION notice denotes a hazard. It calls attention to an operating procedure,

process or similar, which if not correctly performed or adhered to, could cause damage

to the Generator or the Application. Do not proceed beyond a CAUTION notice until the

indicated conditions are fully understood or met.

Caution, risk of electric shock. Ensure power to the Generator has been removed before

proceeding.

MS Table User Manual

Page 8 2014 © Peak Scientific - Rev. 17 - 07/08/14

Declaration of Conformity

We

Peak Scientific Instruments Ltd.

of

Fountain Crescent, Inchinnan. Renfrewshire PA4 9RE

declare that:

Equipment

Nitrogen Gas Generator

Model

MS Table

To which this declaration relates, is in conformity with the applicable EC

Directives, harmonized standards, and other normative requirements.

•

Low Voltage Directive 2006/95/EC

EN 61010-1: 2010

Safety Requirements for Electrical Equipment for Measurement, Control

and Laboratory Use.

CAN/CSA-C22.2 No.61010-1-04

Safety requirements for Electrical Equipment for Measurement, Control

and Laboratory use, Part 1: General requirement.

•

Electromagnetic Compatibility Directive 2004/108/EC

EN 61326-1: 2006

Electrical Equipment for Measurement, Control and Laboratory Use –

EMC Requirements.

•

FCC 47 CFR Part 15 class B

Unintentional radiators; Conducted and Radiated emissions limits.

All evaluation, testing and certification issued by:

Nemko Canada Inc. TUV Product Service Ltd.

303 River Road Octagon House, Concorde Way

Ottawa Segenworth North, Fareham

Ontario Hampshire

Canada England

K1V 1H2

PO15 5RL

Signed By:

Name: Chris Pugh

Position: Engineering Director

Done at: Peak Scientific Instruments Ltd, Inchinnan, Scotland.

Date: 20th of July 2014

MS Table User Manual

Page 9 2014 © Peak Scientific - Rev. 17 - 07/08/14

Environmental Declaration

We

Peak Scientific Instruments Ltd.

of

Fountain Crescent, Inchinnan. Renfrewshire PA4 9RE

declare that:

Equipment

Nitrogen Gas Generator

Model

MS Table

Is fully compliant with the following Directives:

2002/96/EC WEEE (Waste of Electrical and Electronic Equipment)

2002/95/EC RoHS (Restriction of Hazardous Substances)

Peak Scientific Instruments Ltd fully complies with its obligations towards the

European WEEE (Waste of Electrical and Electronic Equipment) Directive

2002/96/EC. These obligations are being met within the B2B compliance

group.

Peak Scientific Instruments Ltd has developed all reasonable ‘due diligence’

controls to ensure that our products comply with the principles and

requirements of the European RoHS (Restriction of Hazardous Substances)

Directive 2002/95/EC. Similar directives in the United States and China, for

example, have also been captured within this program.

Where a specific certificate of compliance is required, this can be requested, on

a product serial number basis, directly from Peak Scientific Instruments Ltd, by

contacting us through our website on www.peakscientific.com

Signed By:

Name: Chris Pugh

Position: Engineering Director

Done at: Peak Scientific Instruments Ltd, Inchinnan, Scotland.

Date: 16th January 2012

MS Table User Manual

Page 10 2014 © Peak Scientific - Rev. 17 - 07/08/14

Technical Specification 1B/1N/1N Hi-Flow

Environment

Min/Max Operating Ambient Temperature

5°C (41°F) / 30°C (86°F)

Maximum Relative Humidity 70% Non-Condensing

Maximum Altitude

2000 meters

Min/Max Storage Temperature*

-20°C (-4°F) / 60°C (140°F)

*NOTE – When taken out of storage the Generator should be allowed to

acclimatize at room temperature for a minimum of 3 hours before operation.

Inlet Conditions

1B

1N

1N Hi-Flow

Min/Max Air Inlet Pressure

N/A

8.3-10 bar / 120-145 psi

Minimum Air inlet Flow

N/A 115 l/min

Generator Outlets

1B

1N

1N Hi-Flow

Curtain Max Flow

N/A

12 L/min (0.42 cfm)

10 L/min (0.35 cfm)

Curtain Max Pressure

N/A

5.50 bar (80 psi)

5.5 bar (80 psi)

Source Max Flow

N/A

26 L/min (0.91 cfm)

22 L/min (0.77 cfm)

Source Max Pressure N/A 7.50 bar (110 psi)

7.5 bar (110 psi)

Exhaust Max Flow

N/A

8 L/min (0.28 cfm)

10 L/min (0.35 cfm)

Exhaust Max Pressure

N/A

4.1 bar (60 psi)

4.1 bar (60 psi)

Dew Point N/A -11°C / 12°F

Purity

N/A

≥95

Particles

N/A

<0.01µm

Phthalates

N/A

NONE

Suspended Liquids

N/A

NONE

Gas Outlets

N/A

3 x ¼” BSPP

Drain Outlet

N/A

1 x ¼” BSPP

Pressure Gauges N/A 3

Start-Up Time For Purity

N/A

30 minutes

Electrical Requirements

Voltage

110-240 VAC

Frequency 50/60 Hz

Current

1 Amp

Input Connection

C14

Fuse T1.6A

Power Cord Type

C13

Pollution Degree

2

Installation Category II

MS Table User Manual

Page 11 2014 © Peak Scientific - Rev. 17 - 07/08/14

General

Dimensions in cm (“) W x D x H 100 x 83 x 80.4 (39.4 x 32.6 x 31.6)

Weight 1B 100 kg 1N 103.5 kg 1N Hi-Flow

103.5

kg

Shipping weight

1B

132.5 kg

1N

135 kg

1N Hi-Flow

135 kg

Noise level 54 dBA @1m

Heat Output

820 BTU / Hr

Technical Specification 2B/2N

Environment

Min/Max Operating Ambient Temperature

5°C (41°F) / 30°C (86°F)

Maximum Relative Humidity

70% Non-Condensing

Maximum Altitude

2000 meters

Min/Max Storage Temperature*

-20°C (-4°F) / 60°C (140°F)

*NOTE – When taken out of storage the Generator should be allowed to

acclimatize at room temperature for a minimum of 3 hours before operation.

Inlet Conditions

2B

2N

Min/Max Air Inlet Pressure

N/A 8.3-10 bar / 120-145 psi

Minimum Air inlet Flow

N/A 115 l/min

Generator Outlets

2B

2N

Curtain Max Flow N/A 18 L/min (0.63 cfm)

Curtain Max Pressure

N/A

5.50 bar (80 psi)

Source Max Flow

N/A

26 L/min (0.91 cfm)

Source Max Pressure

N/A

7.50 bar (110 psi)

Exhaust Max Flow N/A 25 L/min (0.88 cfm)

Exhaust Max Pressure

N/A

4.86 bar (70 psi)

Dew Point

N/A

-11°C / 12°F

Purity N/A ≥95

Particles

N/A

<0.01µm

Phthalates

N/A

NONE

Suspended liquids N/A NONE

Gas outlets

N/A

3 x ¼” BSPP

Drain outlet

N/A

1 x ¼” BSPP

Pressure gauges

N/A

3

Start-Up Time For Purity N/A 30 minutes

MS Table User Manual

Page 12 2014 © Peak Scientific - Rev. 17 - 07/08/14

Electrical Requirements

Voltage 110-240 VAC

Frequency

50/60 Hz

Current

1 Amp

Input Connection

C14 Plug

Fuse

T1.6A

Power Cord Type

C13 socket to local connection (13A minimum)

Pollution Degree

2

Installation Category II

General

Dimensions in cm (inches) W x D x H

100 x 83 x 80.4 (39.4 x 32.6 x 31.6)

Weight

2B

105 kg

2N

108.5 kg

Shipping Weight

2B

137.5 kg

2N

140 kg

Noise Level

54 dBA @1m

Heat Output

820 BTU / Hr

MS Table User Manual

Page 13 2014 © Peak Scientific - Rev. 17 - 07/08/14

Unpacking

Although Peak Scientific takes every precaution with safe transit and

packaging, it is advisable to fully inspect the unit for any sign of transit

damage.

Check ‘SHOCKWATCH’ label for signs of rough handling prior to un-packing –

Any damage should be reported immediately to the carrier and Peak

Scientific or the Peak Partner from where the unit was purchased.

Follow the unpacking instructions posted on the side of the crate. It will require

two people to remove the unit from the shipping crate and to manoeuvre the

Generator onto the floor.

Please save the product packaging for storage or future shipment of the

Generator.

Note: Included with the Generator is a “Fittings Kit” containing mains power

leads for UK, EU and US also all the required fittings. Be careful not to discard

these with the packaging.

MS Table User Manual

Page 14 2014 © Peak Scientific - Rev. 17 - 07/08/14

Installation

Generator Environment

The Generator is designed for indoor use only. It should be

installed adjacent to the application it is supplying. If this is

not convenient then the unit can be sited elsewhere, however,

consideration should be made of the lengths of pipe runs as

pressure drops can result from extended runs of pipe. Please

see the Tubing lengths section for further details.

Performance of the Generator (like all sophisticated

equipment) is affected by ambient conditions. Note should

also be taken to the proximity of Air Conditioning outlets.

These can sometimes give rise to “pockets” of air with high

relative humidity. Operation of the unit within such a pocket

could adversely affect its performance. Consideration should

also be given to the air flow around the unit. It is

recommended that an air gap of 75mm (3”) should be

maintained down both sides, at the rear and across the top of

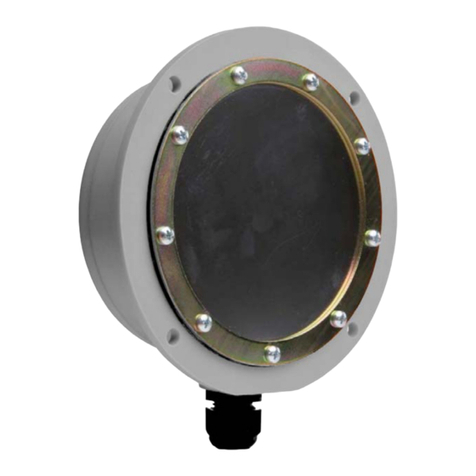

the unit. Please refer to the drawing below for the general

dimensions of the unit.

Maximum Ambient Conditions: 30°C (dry bulb) 70%RH (Max) Non-Condensing

General Dimensions

Figure 1: General dimensions

The Generator must always be placed on a level surface.

Failure to do so will affect the performance of the Generator.

MS Table User Manual

Page 15 2014 © Peak Scientific - Rev. 17 - 07/08/14

Unit Controls

Figure 2: Unit controls

Left Hand Side

Right Hand Side

Fan Power

LED

Exhaust Pressure

Gauge

Source Pressure

Gauge

Curtain Pressure

Gauge

MS Table User Manual

Page 16 2014 © Peak Scientific - Rev. 17 - 07/08/14

Rear Connections

Supplied in the Fittings Kit are all the fittings required to connect the MS Table

Generator to the application. The contents of the Fittings Kit are as follows:

1. 8mm Hex Key × 1

2. Washer M5 Plain × 6

3. Washer M5 Spring × 6

4. Screw M5x16 Pozi Pan Head-BZP x 6

5. C13 Mains Cable (UK) × 1

6. C13 Mains Cable (Euro) × 1

7. C13 Mains Cable (US 220V) × 1

8. C13 Mains Cable (US 110V) x 1

9. Tubing ¼” Teflon 12m Coil

*

× 1

10. Tubing 6mm High Temp. 2m Coil

*

x 1

11. ¼” Swagelok Straight Comp.

*

x 3

12. ¼” Swagelok Straight Push Fit

*

x 1

13. 6mm Blanking Plug x 1

14. User Manual – MS Table × 1

*

MS Table-1N/1N Hi-Flow/2N Only.

Drain Connection – MS Table–1N/1N Hi-Flow/2N only

Use the ¼” tubing (item 9 from fittings kit) to connect the drain outlet to a

suitable drain connection. It should be noted that the Generator can expel a

considerable amount of water from this (dependant on ambient humidity).

If a container is used it should be emptied at regular intervals.

The container must NOT have an air tight seal as water and

air are expelled at pressure.

Figure 3: Rear connections

Power connection

230VAC 50/60Hz

C14 socket

Power cord

04-1038 (EU)

04-1029 (US 220)

04-1028 (UK)

04-1039 (US 110)

Curtain, Source and

Exhaust Outputs

Air Input

Drain

MS Table User Manual

Page 17 2014 © Peak Scientific - Rev. 17 - 07/08/14

Water Bottle Mount Installation

The MS Table is supplied with a water bottle mount, which can be attached to

the left hand side of the unit.

Locate the two mounting holes, as shown in the left image below.

Then, as shown in the right image above, attach the mount to the side of the

unit using two of the M5 plain, and spring washers and M5 pozi pan head

screws contained in the fittings kit.

Infinity 1031 Installation

The MS Table-1N/1N Hi Flow/2N specifically contains an integrated Nitrogen

Generator providing a source of High Purity Nitrogen with 2 independent

additional outlets of clean dry Zero Grade air.

The MS Table-1B/2B does not have an integrated Nitrogen Generator, but does

have the facility to bolt-on to the side of the table a Peak Scientific Instruments

Wall Mounted Infinity 1031 Nitrogen Generator.

Using the remaining M5 fittings from the fittings kit, mount the Infinity 1031 to

the side of the MS Table-2B. Note the front panel of the Infinity 1031 will need

to be removed in order to attach the fittings.

Figure 4: Bottle Mount

Figure 5: Infinity 1031 Mount

MS Table User Manual

Page 18 2014 © Peak Scientific - Rev. 17 - 07/08/14

Levelling Feet

Once the MS Table has been located in its final position, the levelling feet

located at each corner of the unit can be lowered to aid stabilisation.

The TABLE is transported with the feet in a retracted position.

1. Using a 17mm spanner, slacken off

the top nut.

2. Then using a 14mm spanner

unscrew the foot until it

reaches the floor.

3. Unscrew a further 1 full turn before

tightening the locking nut to lock the

foot in place.

4. Repeat this on all four feet, ensuring the unit is level and stable when

finished.

The castors are designed to support the weight of the generator and the

mass spectrometer.

The support feet must be used in conjunction to ensure the MS Table

doesn’t move in operation.

The castors have been tested and proven to support a maximum weight of

250KG

Figure 6: Loosening Top Nut

Figure 7: Unscrew Foot

Figure 8: Lock Foot In Place

MS Table User Manual

Page 19 2014 © Peak Scientific - Rev. 17 - 07/08/14

Electrical Connection

Connect the Generator to a 110-240 VAC volt single-phase supply using the

power cord provided. If the appropriate power cord is not supplied; a new plug,

rated to at least 13 amps, can be fitted by a qualified electrician.

This unit is classified as SAFETY CLASS 1. THIS UNIT MUST

BE EARTHED. Before connecting the unit to the mains supply,

please check the information on the serial plate. The mains

supply must be of the stated AC voltage and frequency.

EARTH/GROUND (E):- Green & Yellow or Green

LIVE (L):- Brown or Black

Neutral (N):- Blue or White

Do not touch anything inside the Generator whilst the side

panels are removed and the mains power is connected to the

unit

Air Connection

The Table–1N/1N Hi Flow/2N Generator should be connected to a clean, dry,

OIL – FREE source of compressed air. A minimum inlet pressure of 120 psig (8.3

barg) is required. Any doubts as to the suitability of your compressed air

supply should be referred to Peak Scientific or any of their authorised partners.

The Compressed Air supply should be connected to the inlet located at the rear

of the unit as shown in the Rear Connections section of this manual.

MS Table User Manual

Page 20 2014 © Peak Scientific - Rev. 17 - 07/08/14

Fan power LED - 2B/2N Only

The LED on the front panel should be illuminated when the Generator is

supplied with power.

This is indication that the fans attached to the front panel are being supplied

with power, and are running correctly.

The front panel should be connected to the power supply as shown below.

Figure 9: Fan Power LED

Figure 10: Fan Power Connection

This manual suits for next models

1

Table of contents