2 Setting

The following describes the setting for the power supply of external devices. If you

do not need this setting, skip this chapter.

2.1 Voltage Supply of External Devices

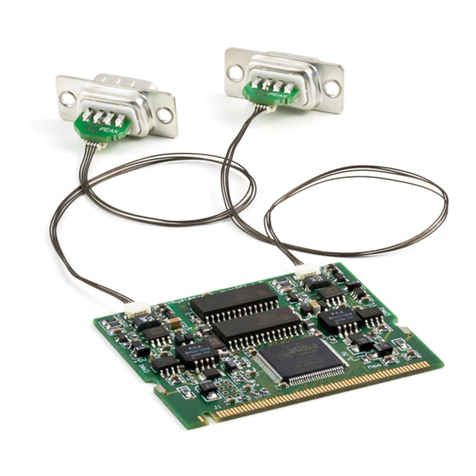

Optionally, an external power supply can be connected separately for each CAN

channel via solder bridges at pin 1 and/or pin 9 on the D-Sub connector. This

allows external devices to be supplied with a voltage of 5 V DC, such as the PCAN-

TJA1054 bus converter for Low-speed CAN. Pin 1 and pin 9 are not connected at

delivery.

The opto-decoupled versions of the card contain an interconnected DC/DC

converter. Therefore, the current output is limited to about 50 mA.

2.1.1 Activate Voltage Supply

Risk of short circuit! Soldering on the CAN interface may only be

performed by qualified electrical engineering personnel.

Attention! Electrostatic discharge (ESD) can damage or destroy

components on the card. Take precautions to avoid ESD.

Set the solder bridge(s) corresponding to the desired settings.

The following figure shows the solder field positions on the quad channel card. The

table below contains the possible settings.

2 Setting PCAN-PCI

User Manual 3.1.0 © 2023 PEAK-System Technik GmbH

8