1.1 Properties at a Glance

NXP LPC21 series microcontroller (16/32-bit ARM CPU)

32 kbyte EEPROM

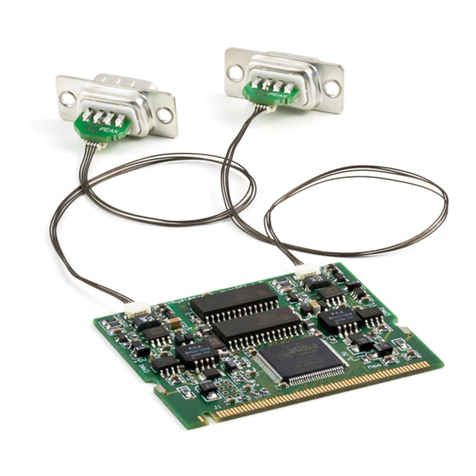

Two High-speed CAN channels (ISO 11898-2)

Comply with CAN specifications 2.0 A/B

Bit rates from 5 kbit/s up to 1 Mbit/s, adjustable with a rotary switch

NXP PCA82C251 CAN transceiver

Reset of the device with a push button

Switchable termination for each CAN channel

Status indication via LEDs for the module status, both CAN channels, and the

power supply

Connections for CAN, RS-232, and power supply via 4-pole screw-terminal strips

(Phoenix)

CAN 1 is isolated up to 5 kV against CAN 2, RS-232, and the power supply

(compliant with IEC 60601-1)

CAN 2 and RS-232 are isolated with 500 V against each other and against the

power supply

Plastic casing (width: 22.5 mm) for mounting on a DIN rail (DIN EN 60715 TH35)

Voltage supply from 8 to 30 V

Extended operating temperature range from -40 to +85 °C (-40 to +185 °F)

RS-232 connector for serial data transfer (reserved for future use)

New firmware can be loaded via CAN interface

1 Introduction PCAN-RouterDR

User Manual 3.0.0 © 2023 PEAK-System Technik GmbH

6