PCAN-Router Pro – User Manual

5

1Introduction

The PCAN-Router Pro allows to join the data traffic from four High-

speed CAN buses. The behavior of the router is configured via the

CAN bus with the provided Windows program PPCAN-Editor 2. As

well as pure forwarding, the CAN data can be processed,

manipulated, and for example, filtered in a number of different

ways. There are a variety of function blocks and other settings

available to the user for configuration setup. Furthermore, there is a

virtual fifth CAN channel which is used for recording all data traffic

to a CompactFlash card.

As an alternative to the standard firmware which the PCAN-Router

Pro is equipped with at delivery, custom firmware based on the

ARM microcontroller NXP LPC2294 can be created and

implemented. The firmware is created using the included

development package with GNU compiler for C and C++ and is then

transferred to the module via CAN. Various programming examples

facilitate the implementation of own solutions.

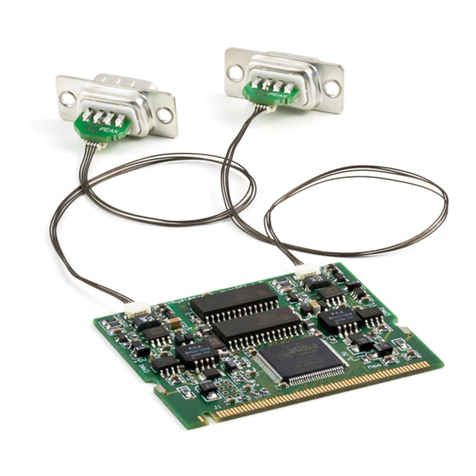

CAN transceiver modules in the PCAN-Router Pro allow a flexible

adaptation of each CAN channel to the requirements. For example,

Low-speed and Single-wire CAN transceivers are also available on

request.

The documentation for the PCAN-Router Pro has multiple parts:

PCAN-Router Pro - User Manual (this document):

Explains hardware adjustments, the operation of the device, and

the hardware-specific settings in the PPCAN-Editor 2 (Appendix

E on page 63).

PPCAN-Editor 2 - Documentation (program help):

The help of the configuration program PPCAN-Editor 2 for

Windows, accessible via the Help menu or via F1.