English (US) Installation and operating instructions

Original installation and operating instructions

Table of contents

1.

General information ........................2

Limited warranty ...........................2

Hazard statements..........................3

Notes ..................................3

Target group. .............................3

General safety warnings ......................3

Material safety data sheet .....................4

Noise level. ..............................4

2. Identification .............................7

2.1 Nameplate ...............................7

2.2 Certifications .............................7

2.3 Pump size and model ........................7

2.4 Type key for in-line fire pump ..................9

3. Receiving the product ......................9

3.1 Unpacking the product ......................9

3.2 Transporting the product .....................9

3.3 Inspecting the product. .....................9

3.4 Scope of delivery ..........................9

3.5 Handling and storing the product after delivery........9

4.Installing the product ......................9

4.1 Factory support ...........................9

4.2 Location ...............................9

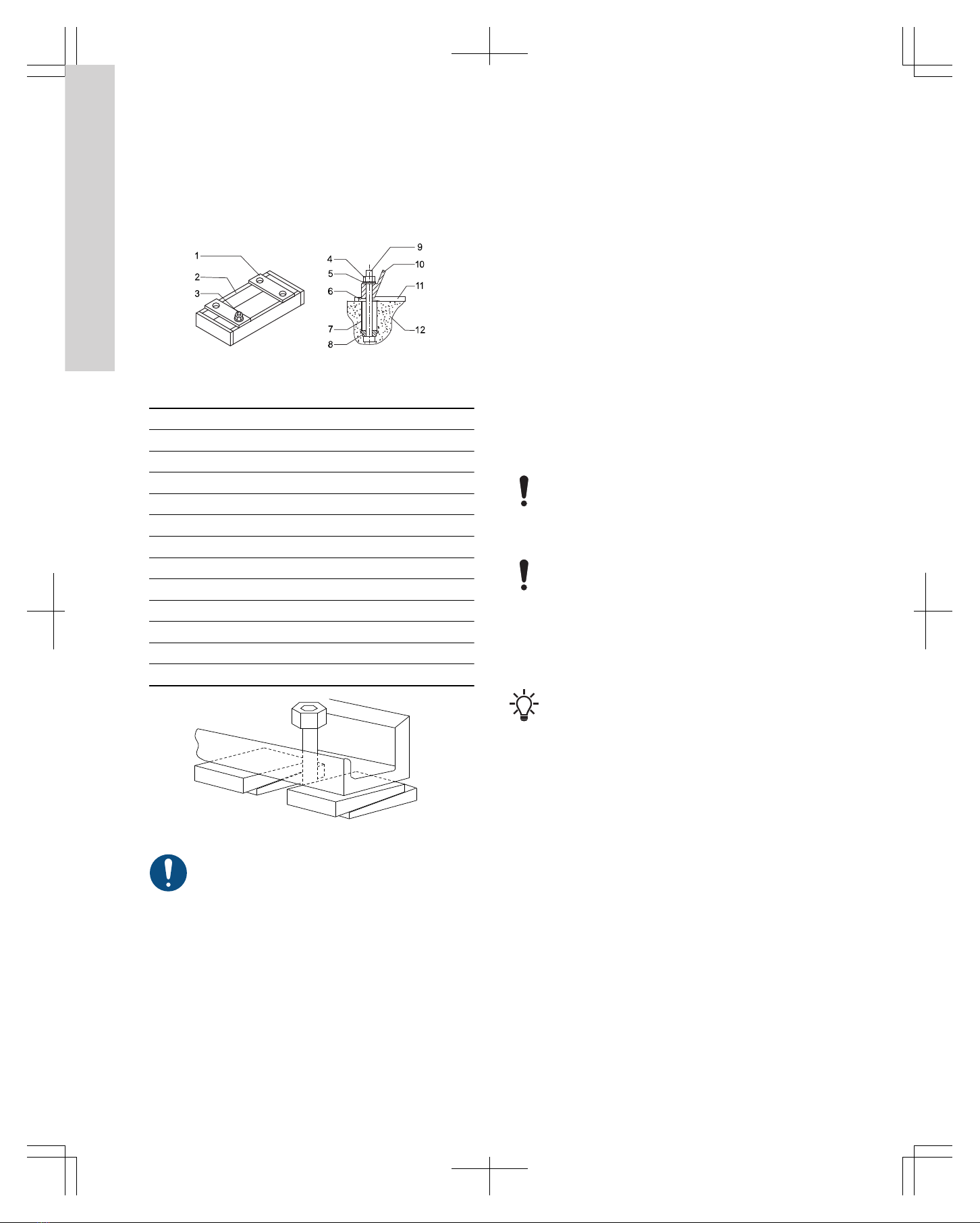

4.3 Foundation .............................10

4.4 Installation preparations. .....................10

4.5 Mechanical installation ......................12

4.6 Pipes and connections ......................12

4.7 Lubrication, priming and cooling systems ...........13

4.8 Electrical installation ........................13

4.9 Control, monitoring, and alarm equipment. ..........13

5. Starting up the product .....................13

5.1 Lubricating the pump .......................13

5.2 Checking rotation. .........................14

5.3 Check list ..............................14

5.4 Starting up the product ......................14

6.Service ...............................15

6.1 Maintenance ............................15

6.2 Maintenance schedule ......................15

6.3 Recommended spare parts ...................16

6.4 Consumables ............................16

6.5 Tightening torques .........................16

6.6 Dismantling the pump .......................16

6.7 Wear ring ..............................17

6.8 Replacing the wear ring ......................17

6.9 Inspecting the product. ......................17

6.10 Repairing the product .......................17

6.11 Assembling the pump .......................17

6.12 Accessories .............................18

7. Storage / handling the product ................18

7.1 Storage. ...............................18

7.2 Handling the product .......................19

7.3 Frost protection ...........................19

8. Fault finding / Fault finding the product ..........20

8.1 Parts list and sectional drawings ................22

9. Disposing of the product ....................22

1. General information

1.1 Limited warranty

New equipment manufactured by seller or service supplied by seller

is warranted to be free from defects in material and workmanship

under normal use and service for a minimum of twelve (12) months

from date of installation, eighteen (18) months from date of

shipment, unless otherwise stated in product warranty guide

(available upon request). In the case of spare or replacement parts

manufactured by seller, the warranty period shall be for a period of

twelve months from shipment. Seller's obligation under this

warranty is limited to repairing or replacing, at its option, any part

found to its satisfaction to be so defective, provided that such part

is, upon request, returned to seller's factory from which it was

shipped, transportation prepaid. Parts replaced under warranty shall

be warranted for twelve months from the date of the repair, not to

exceed the original warranty period. This warranty does not cover

parts damaged by decomposition from chemical action or wear

caused by abrasive materials, nor does it cover damage resulting

from misuse, accident, neglect, or from improper operation,

maintenance, installation, modification or adjustment. This warranty

does not cover parts repaired outside seller's factory without prior

written approval. Seller makes no warranty as to starting

equipment, electrical apparatus or other material not of its

manufacture. If purchaser or others repair, replace, or adjust

equipment or parts without seller's prior written approval, seller is

relieved of any further obligation to purchaser under this paragraph

with respect to such equipment or parts, unless such repair,

replacement, or adjustment was made after seller failed to satisfy

within a reasonable time seller's obligations under this paragraph.

Seller's liability for breach of these warranties (or for breach of any

other warranties found by a court of competent jurisdiction to have

been given by seller) shall be limited to: (a) accepting return of such

equipment exw plant of manufacture, and (b) refunding any amount

paid thereon by purchaser (less depreciation at the rate of 15% per

year if purchaser has used equipment for more than thirty [30]

days), and canceling any balance still owing on the equipment, or

(c) in the case of service, at seller's option, redoing the service, or

refunding the purchase order amount of the service or portion

thereof upon which such liability is based. These warranties are

expressly in lieu of any other warranties, express or implied, and

seller specifically disclaims any implied warranty of merchantability

or fitness for a particular purpose, and in lieu of any other obligation

or liability on the part of the seller whether a claim is based upon

negligence, breach of warranty, or any other theory or cause of

action. In no event shall seller be liable for any consequential,

incidental, indirect, special or punitive damages of any kind. For

purposes of this paragraph, the equipment warranted shall not

include equipment, parts, and work not manufactured or performed

by seller. With respect to such equipment, parts, or work, seller's

only obligation shall be to assign to purchaser the warranties

provided to seller by the manufacturer or supplier providing such

equipment, parts or work. No equipment furnished by seller shall be

deemed to be defective by reason of normal wear and tear, failure

to resist erosive or corrosive action of any fluid or gas, purchaser's

failure to properly store, install, operate, or maintain the equipment

in accordance with good industry practices or specific

recommendations of seller, including, but not limited to seller's

installation and operation manuals, or purchaser's failure to provide

complete and accurate information to seller concerning the

operational application of the equipment.

4