MG125-4 PEGAS 200 AC-DC PULSE SERVICE MANUAL page 1

ALFA IN a. s. © 2012 SERVISNÍ TECHNICKÁ DOKUMENTACE

SERVISNÍ MANUÁL PEGAS 200 AC-

DC PULSE SERVICE MANUAL PEGAS 200 AC-

DC PULSE

1. VAROVÁNÍ WARNING

UPOZORNĚNÍ – Pouze osoba splňující

kvalifikaci danou zákonem je oprávněna

opravovat stroj.

PŘED OTEVŘENÍM KRYTU STROJE JEJ

ODPOJTE VYTAŽENÍM SÍŤOVÉ VIDLICE ZE

SÍTĚ.

Každé 4 měsíce otevřete stroj a jemněho

vyfoukejte stlačeným suchým vzduchem

POZOR, NEPOUŽÍVEJTE STLAČENÝ

VZDUCH O PŘÍLIŠ VYSOKÉM TLAKU, ABY

NEDOŠLO K MECHANICKÉMU POŠKOZENÍ

ELEKTROSOUČÁSTEK.

Každé 4 měsíce zkontrolujte řádný stav

svařovacích kabelůa síťových kabelů.

Není povolena žádná modifikace

svařovacího stroje.

Pro Vaši bezpečnost je nutné posečkat se

sundáním krytu ze stroje po odpojení ze sítě

po dobu minimálně5 minut, kdy klesne

napětí na kondenzátorech na hodnotu pod

36 V.

NOTE Only trained personnel are

permitted to work inside the machine.

BEFORE OPENING THE MACHINE, CUT

OFF ITS ELECTRICAL POWER BY

REMOVING THE PLUG FROM THE MAINS

SUPPLY SOCKET.

Every six months, open the machine and

clean it inside, using compressed

dehumidified air.

CAUTION. DO NOT USE COMPRESSED

AIR AT TOO HIGH A PRESSURE. YOU

COULD DAMAGE THE ELECTRONIC

COMPONENTS.

With the same frequency, check the

welding cables and the supply cables.

No modification, of any type, may be

made to the welding machine.

For safety while maintaining the machine,

please shut off the supply power and wait

for 5 minutes, until capacity voltage

already drops to safe voltage 36V.

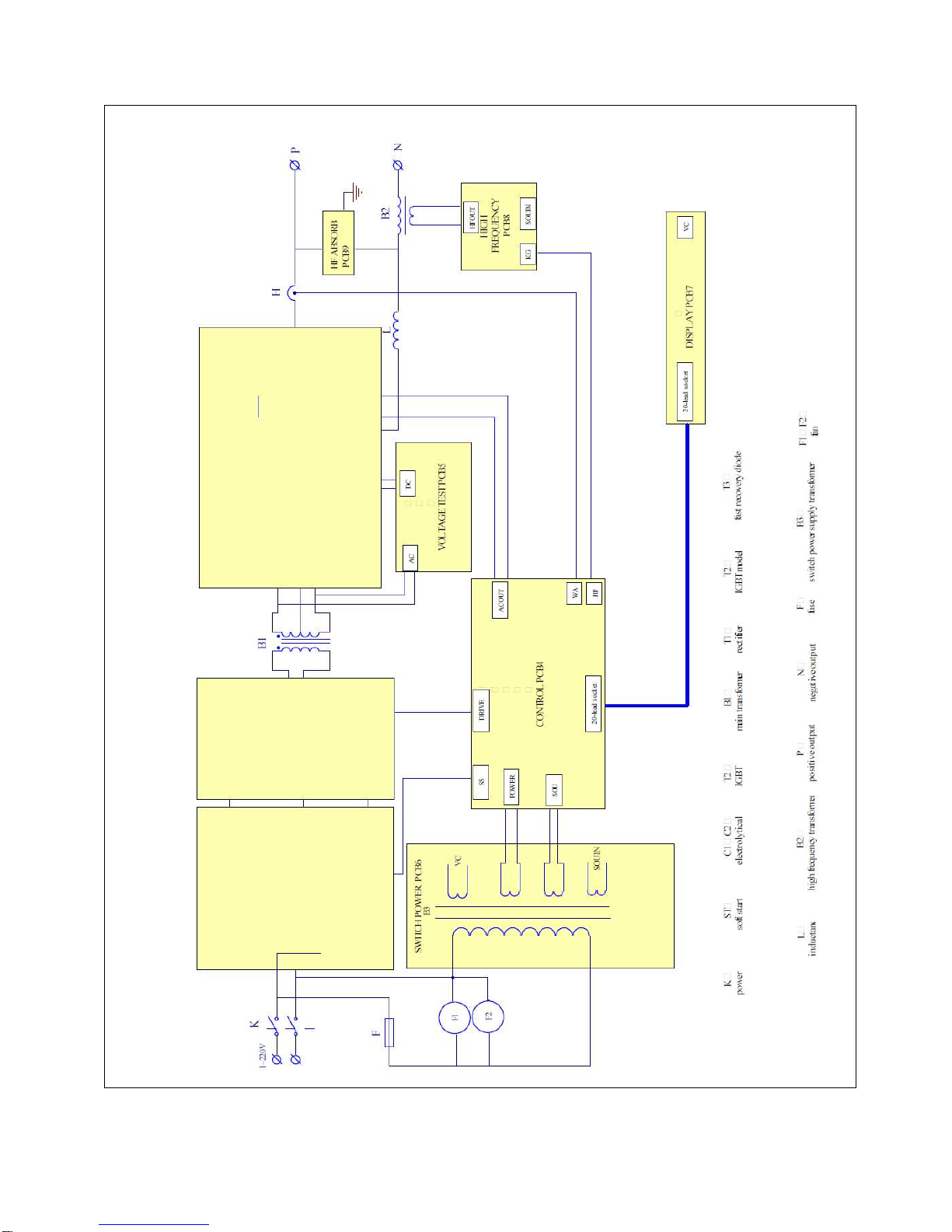

2. BLOKOVÉ SCHÉMA ELECTRICAL PRINCIPLE DRAWING