PX-3A and PX-5A

DISASSEMBLY

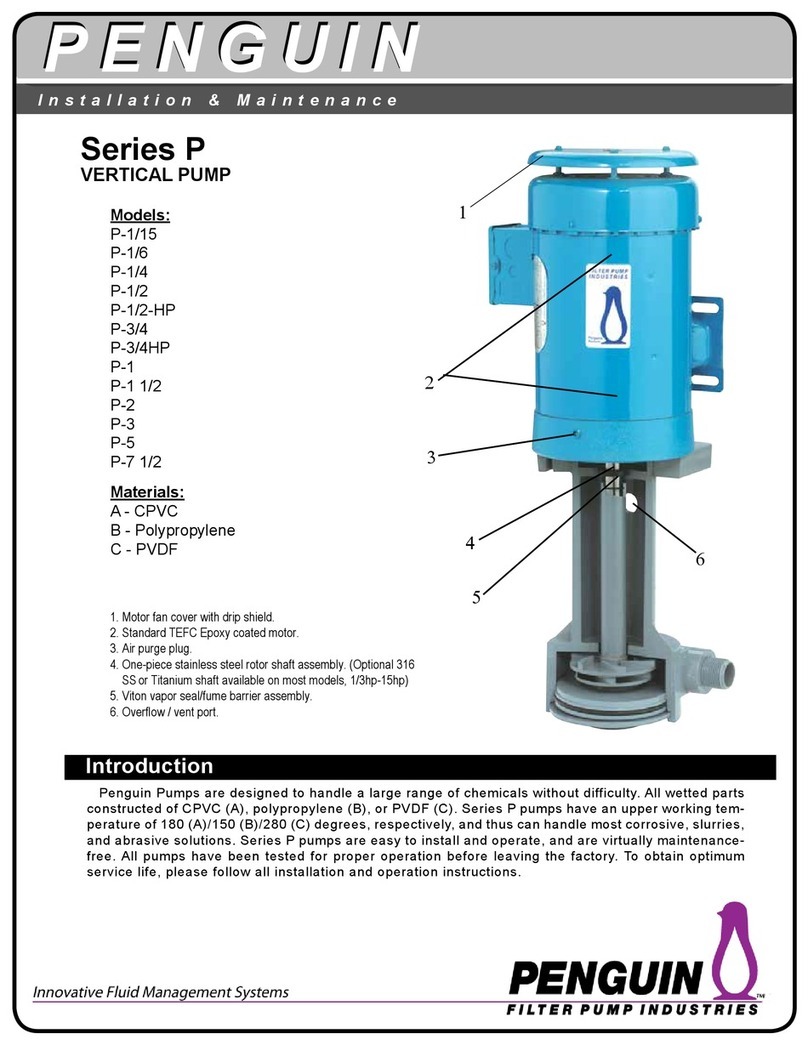

1. Remove the four (4) snap ring screws. Now the snap ring can be removed using a screwdriver or a pair of pliers.

2. Insert a 2 inch threaded pipe through the center hole at the end of the housing to remove the head. Pull with a rocking motion to remove. Caution

must be used because of the close tolerance between the impeller and wear O-ring. Head O-rings can easily be replaced.

3. Unscrew the fan cover screws and remove the fan cover and drip shield. Place the screwdriver between fan blades and unscrew the impeller nut

using a 3/4 inch open wrench in a counterclockwise rotation. Impeller nut O-ring can be replaced.

4. With the pump in a vertical position, impeller up, place a screwdriver through the discharge port, wedging between the impeller top and the

housing. Carefully lift the impeller and remove. If impeller does not remove easily, proceed to step 5.

5. Remove the four (4) motor bolts located beneath the motor bracket. Motor and housing are now separated. Do not try to remove shaft as this is an

integral piece with the motor rotor. Slinger and lip seal can be replaced. Using a rubber mallet, hit the pump bracket lightly, top side facing motor,

until the impeller and keyway pop loose.

ASSEMBLY

1. With the motor in a vertical position, shaft upwards, place the four motor spacers over the motor bolt holes. Place housing over shaft, lining up

motor bolt holes in the mounting bracket with holes in the motor. Be sure the V-Seal slinger is properly in place. Screw the motor bolts into the

holes beneath the mounting bracket in a diagonal sequence.

Be sure motor screws are tight.

2. Insert the impeller into the housing until it bottoms out. Do not hammer the impeller and sleeve down on the shaft. Line up the keyway and insert

key by lightly tapping it with a hammer. Screw the impeller nut clockwise holding impeller. Be sure impeller nut O-ring is properly in place. After

handtight, turn with wrench 180 degrees.

DO NOT OVERTIGHTEN.

3. Replace the fan cover and drip shield. Insert the fan cover screws and tighten. Be sure fan is not rubbing against fan cover.

4. Place the pump upright resting on the motor. Look down into the housing and, while rotating the impeller, check to see that the impeller is

centered. The impeller must not be touching the side of the housing.

5. Wet head and head O-rings. Be sure head O-rings are properly in place. Insert 2 inch threaded pipe into the head and replace in housing. The

threaded pipe should be tapped with a mallet, pushing the head into the housing until the snap ring groove is exposed. Remove pipe and replace

snap ring. Line up through holes in snap ring with the threaded holes in the head by rotating the snap ring counterclockwise. Insert and tighten the

four (4) snap ring screws.

PX-7 1/2A-HF thru PX-15A-HF

DISASSEMBLY

1. Unscrew and remove discharge piping. Remove the six (6) snap ring screws. Now the snap ring can be removed using a screwdriver or a pair of

pliers.

2. With a rubber mallet, gently hit the back of the suction casing, alternating blows from one side to the other until the suction casing comes off.

Suction casing O-ring can easily be replaced.

3. Unscrew the impeller nut using a 3/4 inch socket wrench in a counterclockwise rotation. Impeller nut O-ring can be replaced.

4. Thread a 3/4-10UNC bolt into the hole in the center of the impeller eye. Holding the impeller, using an appropriate wrench turn the bolt clock-

wise until the impeller slips off the shaft.

ASSEMBLY

1. Unscrew the fan cover screws and remove the fan, fan cover, and drip shield assembly.In order for the motor to stand on end, the fan shaft must be

placed in a hole deep enough for it to sit flat on the end bell. With the motor in a vertical position, shaft upwards, place the four motor spacers

over the motor bolt holes. Place housing over shaft, lining up motor bolt holes in the mounting bracket with holes in the motor. Be sure the slinger

is properly in place. Screw the motor bolts into the holes beneath the mounting bracket in a diagonal sequence.

Be sure motor screws are tight.

2. Using loctite or other type of threadlocker, secure key into keyway on shaft. Insert the impeller into the housing. Rotate to engage key and slide or

lightly tap into place until it bottoms out. Do not hammer the impeller and sleeve down on the shaft. Screw the impeller nut clockwise holding

impeller. Be sure impeller nut O-ring is properly in place.After handtight, turn with wrench 180 degrees.

DO NOT OVERTIGHTEN.

4. Place the pump upright resting on the motor. Look down into the housing and, while rotating the impeller, check to see that the impeller is

centered. The impeller must not be touching the side of the housing.

5. Lubricate support casing and casing O-ring. Be sure casing O-ring is properly in place. Slide suction casing over support casing, lining up timing

marks to assure proper fit. Using a soft mallet, tap suction casing down onto support casing until snap ring groove is exposed. Line up through

holes in snap ring with the threaded holes in the support casing by rotating the snap ring clockwise. Insert and tighten the six (6) snap ring screws.

Maintenance Instructions

Filter Pump Industries

7932 Ajay Drive • Sun Valley, CA91352

Voice: (818) 504-2391 • Fax: (818) 768-7590