Models:

PX-7 1/2-HF

PX-10-HF

PX-15-HF

Materials:

A - CPVC

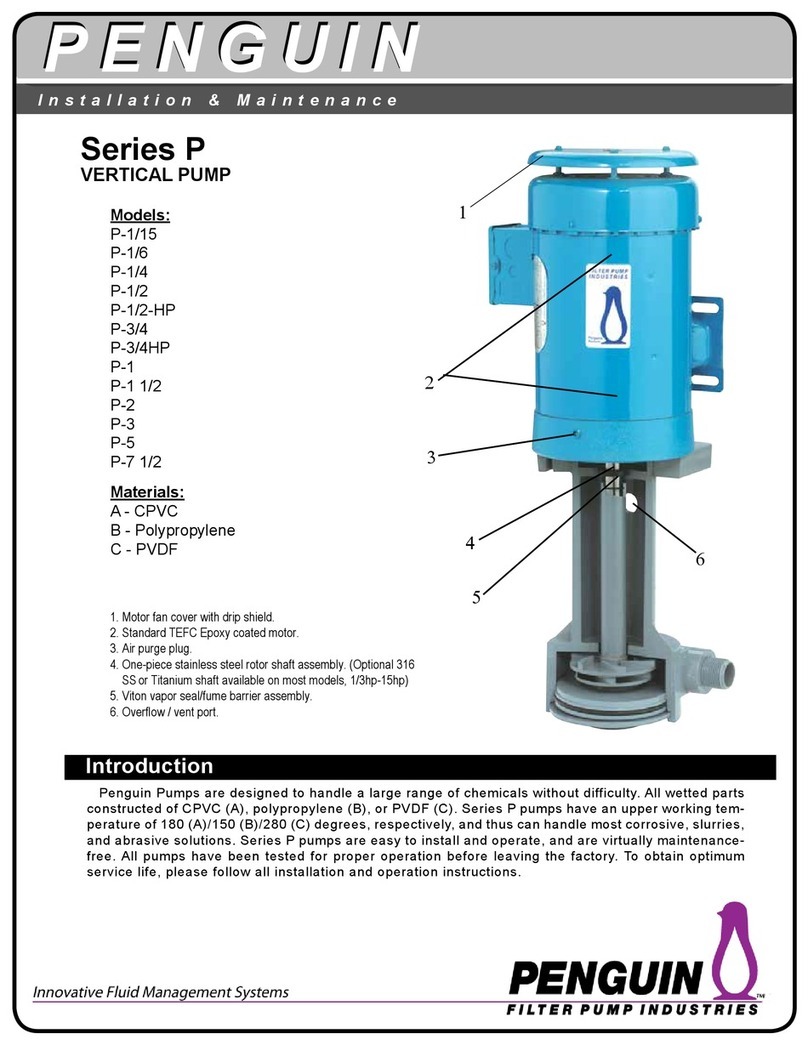

Penguin Pumps are designed to handle a large range of chemicals without difculty. Completely

constructed of CPVC where in contact with the solution being pumped, Series PX pumps have an

upper working temperature of 180 degrees and thus can handle slurries, and most corrosive and

abrasive solutions. Series PX pumps are easy to install and operate, and are virtually mainte-

nance-free. All pumps have been tested for proper operation before leaving the factory. To obtain

optimum service life, please follow all installation and operating instructions.

Series PX-HF

ELECTRICAL

PLUMBING

LIQUID LEVEL

PRIMING

All models are supplied with three phase dual voltage, 208-230/460V,

50/60c motors, which are not wired at the factory. When changing from

230V wiring to 460V wiring, follow the motor manufacturer’s wiring

instructions, which can generally be found either on or in the motor

junction box. Check rotation of external fan by removing splash shield,

fan spins clockwise. It is imperative that the motor rotation be checked

before operation. Attach leads to motor and bump start for a maximum

of a couple of seconds as if you were turning a light switch on/off as fast

as possible. Do not leave motor running. As viewed from the suction

entrance of the pump, check for counterclockwise rotation. If clockwise

rotation, change any two hot leads and again check rotation. Replace

fan splash shield. Many options are available on the PX Series motors

including explosion-proof, larger horsepowers to 15, and 575V motors.

If any of these options are required, please check the motors carefully

or consult the factory.

The suction side piping of the pump is extremely important.

Mistakes can usually be compensated for if made on the discharge

piping. However, piping problems on the suction side can be, and

usually are, the source of ongoing problems. If a suction line

or suction extension is required, enlarge the suction line/exten-

sion by one size larger than the suction entrance. Never reduce

plumbing on the suction. Avoid 90-degree elbows and never use

a 180-degree elbow. The suction piping needs to be arranged in

such a way as to allow a straight, even ow of liquid into the eye

of the impeller. This requires that all elbows, valves, or strainers

be located at a straight and uninterrupted distance equal to at

least 5-10 times the pipe diameter. Remember, elbows create

turbulence and air entrapment. Make sure every suction coupling/

connection is airtight. The bottom of the suction extension should

always be at least 2 pipe diameters above the bottom of the tank.

In either ooded suction or non-ooded suction conditions the use

of a check valve on the discharge of the pump is recommended. In

The correct liquid level is very important. A liquid level which is too high

could cause motor damage. A liquid level that is too low, below the wear

ring, may cause severe impeller damange, THIS PUMP CANNOT RUN

DRY. CHECK THE LIQUID LEVEL. The correct liquid level is halfway

between the bung hole and the centerline of the discharge nozzle.

Under ooded conditions, open all the valves in the suction and

discharge lines. Wait a few minutes to let entrapped air out. Throttle the

discharge valve 2/3 closed. Leave suction valves wide open. A closed

suction or discharge valve could cause damage to the impeller and the

shaft. Start the pump and open the valve to the desired ow. Under

non-ooded conditions, ll up the pump slowly from the T-connection

and valve. See recommended installation. Then throttle the discharge

valve 2/3 closed. Start the pump and continue as ooded conditions.

Installation & Operating Instructions

PLUMBING CONTINUATION

the case of a non-ooded suction, a apper check valve on the end of

the submerged suction line must be installed. To facilitate priming the

pump, install a T-connection with a small valve between the pump case

and check valve. It is advisable to use a discharge valve after the check

valve. All plumbing and accessories must be supported other than by

the pump, in order to prevent possible distortion of the pump case. The

use of some hose in the discharge plumbing close to the discharge

nozzle of the pump will absorb any movement of the solid plumbing if

vibrations exists. Also a good rule of thumb is that the source solution

tank volume should be three times the ow rate of the pump.

EXTENDED VERTICAL HIGH FLOW

Installation & Maintenance

PENGUIN

PENGUIN