7

Operation & maintenance

1. Choose the correct nozzle according to requirements, and use tools to lock the

nozzle screw to prevent it from falling off suddenly during work;

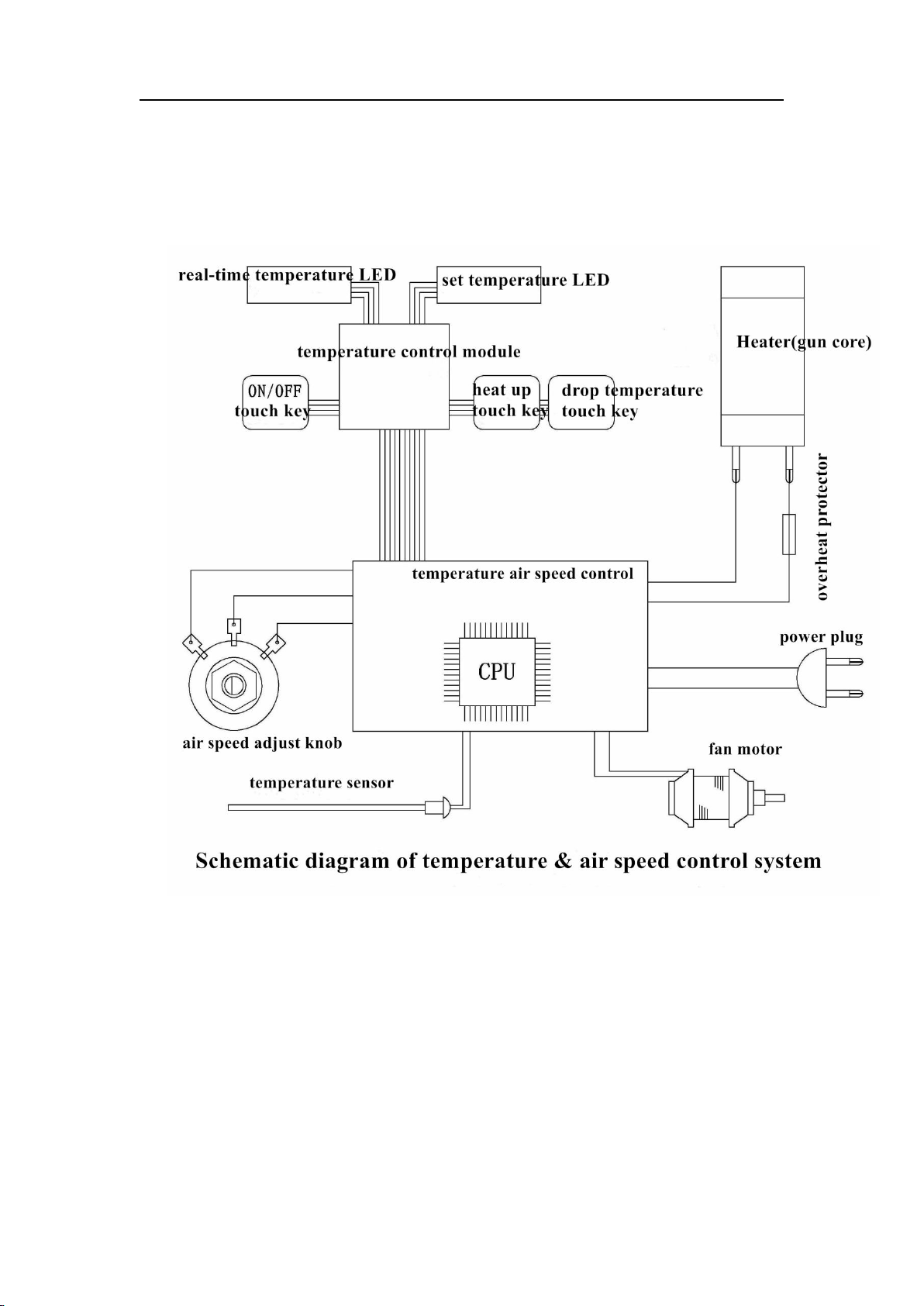

2. Plug in the power supply, check the safety of the environment and check whether

the working voltage of the welding gun meets the requirements of the rated voltage;

3. Long press the POWER button for three seconds, the LED indicator will light up

and display "ON", and the machine will enter the working state;

4. Press the up and down arrow keys to adjust the set temperature. Long press is the

quick adjustment mode; The value on the red light is the set temperature value; the

value on the yellow light is the real-time temperature value;

5. Adjust the air volume & knob to the required air volume;

6. After use, press and hold the POWER button for three seconds, the LED will

display "OFF" and enter the shutdown mode. The machine will automatically

continue to blow cold air until the nozzle temperature drops to the design temperature,

and then automatically shut down.

7. When it is turned on again, the machine will directly memorize the temperature

value set last time, which is convenient to use and operate;

8. Regularly clean the dust on the air inlet filter with a small brush, and keep the air

inlet clean at any time;

9. Frequently clean stainless steel air ducts and nozzles to prevent clogging of the

nozzles and corrosion of stainless steel;

10. When the carbon brush is consumed to the min. length, the machine will

automatically stop. The service life of the carbon brush is about 1600 hours. If the

carbon brush requires to be replaced due to the consumption, please hand it over to a

professional electrician or maintenance company to replace a qualified carbon brush;

11. Make accurate use of the machine's automatic delayed cooling shutdown function,

and don’t forcibly unplug the power supply during the automatic cooling.