Work Area

TO AVOID RISK OF PERSONAL INJURY, EQUIPMENT DAMAGE, FIRE AND SHOCK, MAKE SURE YOUR

WORK AREA IS:

Free of damp, wet or rainy conditions.

Free of children (never let them handle tools or machinery).

Well-lit.

Clean and uncluttered.

Before Operating

Before using any tool, any part that appears damaged should be carefully checked to determine that it will

operate properly and perform its intended function.

Before operating your Swivel Vise check for damaged parts.

Assembly

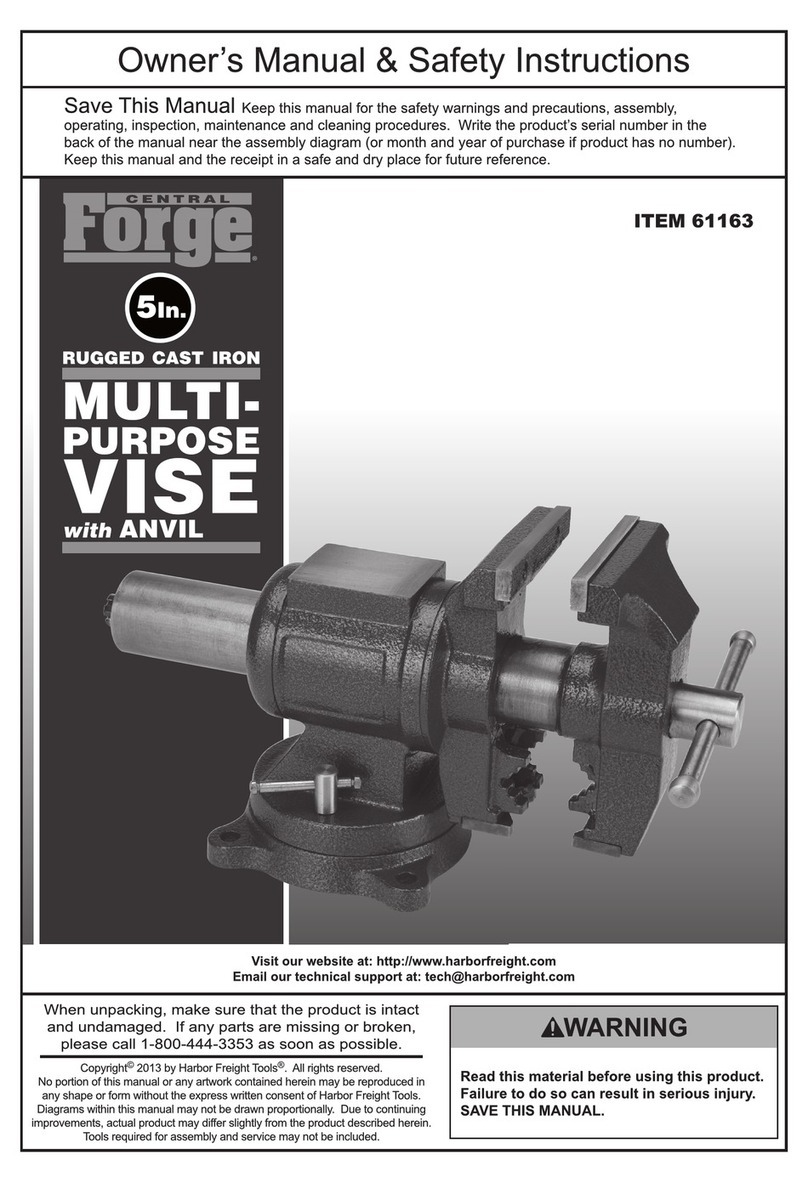

Your Vise comes completely assembled. Before proceeding, wipe down your vise with a degreasing solution

or dish soap and water to remove any packaging grease.

Your Swivel Vise comes with mounting holes on the Base Foot. Use the appropriate hardware to secure the

vise to your workbench. Make sure the vise is securely mounted before using.

It is important that your read the entire manual to become familiar with the unit BEFORE you use the Swivel

Vise. Before assembling your Swivel Vise, be sure that you have all parts described in the Parts List.

Assemble attachments based on the intended use of the tool.

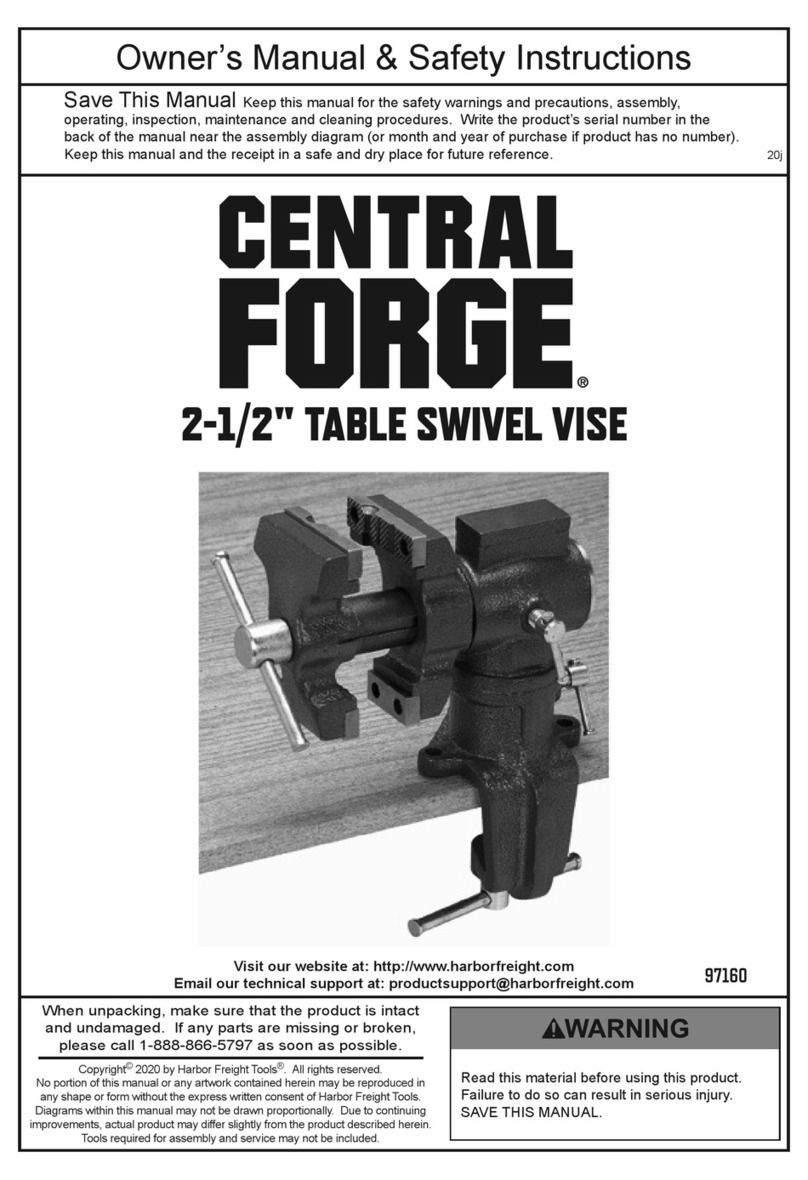

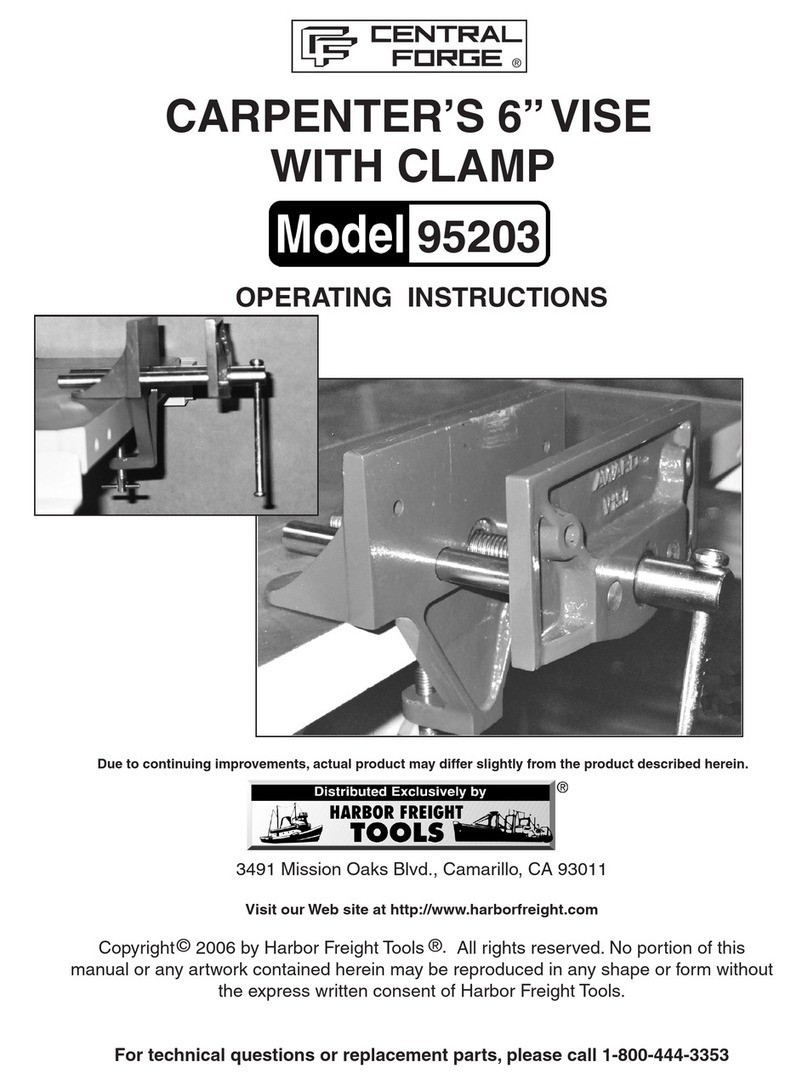

Mounting the Vise to a Wooden Workbench (See Figure 1 )

Step 1) Measure the thickness of your workbench. To securely mount your vise to a

wooden workbench, mount 2” W x 2” H x 2” L lengths of wood underneath the

mounting points for the vise in order to add strength.

Step 2) Purchase three bolts, nuts, and flat washers the appropriate length of your

workbench and add one inch (1”) of length to the bolts to make up for the extra

inch of the vise.

Step 3) Mark and drill the holes through the workbench, using the base as a template, for the

mounting tabs on the base of the vise.

Step 4) Position the vise on the workbench and line up the holes drilled in Step Three with the holes

in the mounting tabs.

Step 5) Insert the Bolts into the mounting tabs and through the workbench as shown in Figure 1.

#32114 Page 3Rev 10/99

Brought To You By Augusta Flint