6.0 INSTRUCTIONS FOR MERTIK MAXITROL GV60 GAS CONTROL

Ensure that the fuel supplied to the unit is clean and free from particles and moisture.

Before a gas supply pipe (new or existing) is connected to the main gas pipe at the gas meter and to the gas

control block of the unit, clean and dry compressed air should been blown through it. Cut copper pipes as well as

aluminium pilot pipes must be deburred and blown clean before they are connected. The dust filter at the

connection to the gas control block will only filter out the coarsest dirt from the system. Fine particles are still

able to reach the inside and may damage and/or adversely affect regulation in the gas control block.

Heat, moisture and dust are a threat to all electronic components.

Protect the electronic gas control until all construction, plastering and paintwork has been completed. If such

work cannot be avoided, then protect the control against dirt and moisture penetration by using, for example

plastic film.

Only place the batteries after wiring to the receiver, gas control block and pilot set is connected.

Premature connection to the energy source may damage the control’s CPU (central processor).

Ensure that the ignition cable is not near the antenna wire and that they do not cross each other.

The high voltage released at ignition may damage the sensitive receiver circuit. This may mean that the unit

becomes less responsive or not responsive at all to handset commands.

Prevent leakage of the ignition spark to other parts of the installation than the Ignition by the pilot.

Keep the ignition free of hull or other metal parts. If cable extension is used, see to it that connections are

additionally insulated with a silicone grommet.

For automatic start via the transmitter, the receiver and the control the gas control valve should be

switched.

The oval disk on the gas control block should be turned to the ON position. The I/0 switch should to be set to

"I". The ignition must be connected to the receiver box at the terminal SPARK.

The transmitter's contains the thermostat sensor system.

The transmitter operates best at 2 to 3m from the unit. Although the communication via short wave radio

signals takes place, it is recommended that the transmitter in the 'visibility' of to lay the gas apparatus in

a place where the user wants to experience a pleasant temperature. Place the hand transmitter in direct

sunlight or other hot places. The thermostat measures the temperature and regulates the flame size of the

gas in accordance.

Remove batteries only with the red ribbon which is under the battery, not with a metal tool.

Removing batteries with a metal object can permanently damage the electronic control.

IMPORTANT: Electronic components will become permanently faulty when exposed to temperatures higher

Than 60°C. Standard AA batteries will crack open at temperatures >54°C and the battery contents will

damage the electronic switches located underneath. Batteries last longest at <25°C. At >50°C the life span is

around 23 weeks, this makes the use of the gas fire unnecessarily expensive.

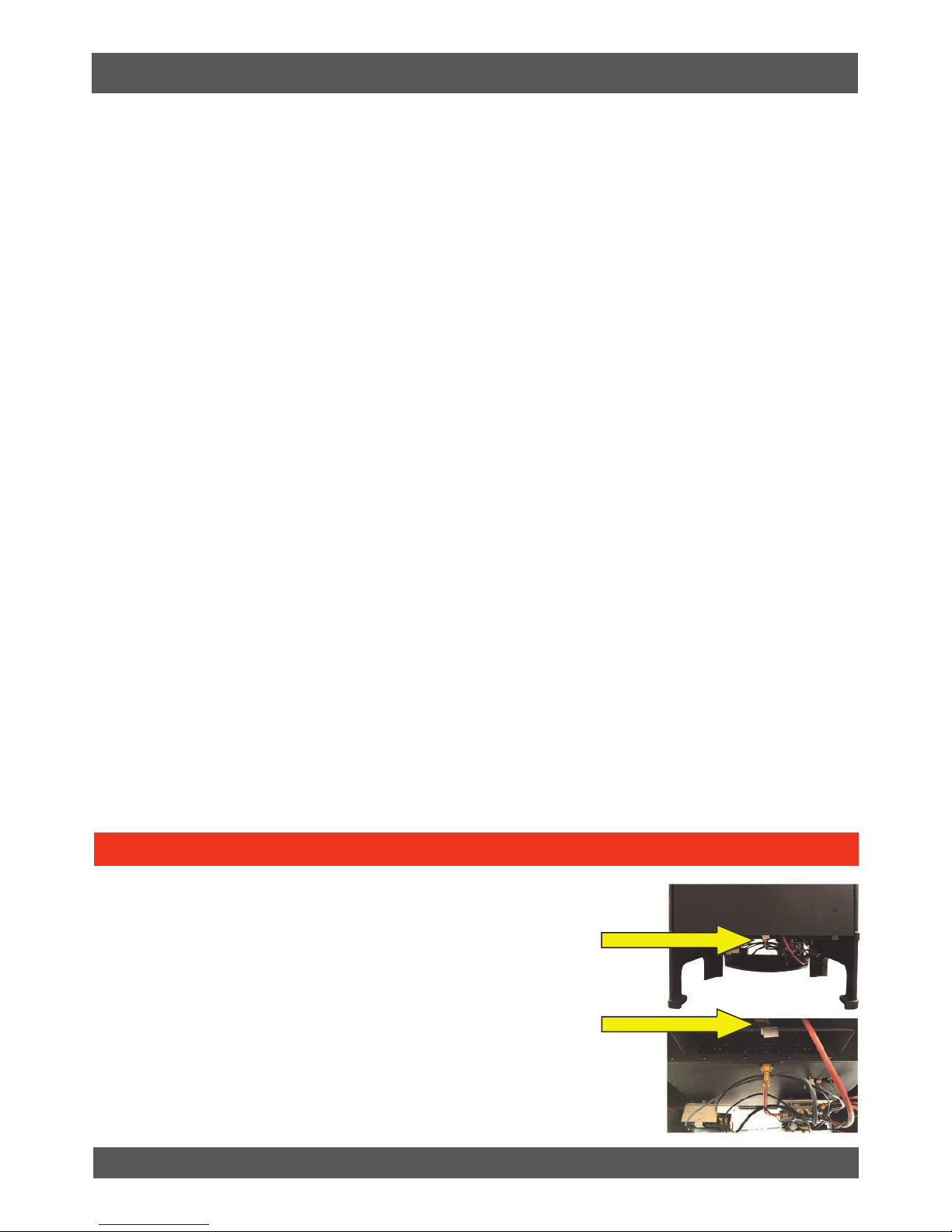

Only install the gas control block and receiver as pre-installed at the factory.

Remember that components may have to be replaced or that repairs may have to be performed at a later date.

This may be more difficult if the control is installed using a method that is different from the instructions

provided here.

NOTE: Do not tighten the contact breaker and the thermocouple connection too tightly on the gas

control block or to each other. It is sufficient to tighten by hand and add a half a turn with an open-end

spanner. Tightening too much will break the connection to the magnetic coil below and/or the insulation

around the aluminium contact pin in the contact breaker. This may lead to the magnetic coil not opening the

gas supply to the pilot and the unit not working.

PAGE 10

IMPORTANT: Do not start up the unit if the window is not present or broken.