Rev. B 2-26-10 P/N 474131

3

Table of Contents

Section 1. Heater Identification Information ....................................................................... 4

Section 2. Introduction .......................................................................................................... 5

ImportantNotices................................................................................................................................................................................. 5

WarrantyInformation ............................................................................................................................................................................ 5

CodeRequirements.............................................................................................................................................................................. 6

ConsumerInformationandSafetyInformation ...................................................................................................................................... 6 - 8

GeneralSpecifications ......................................................................................................................................................................... 8

Section 3. Installation ............................................................................................................. 9

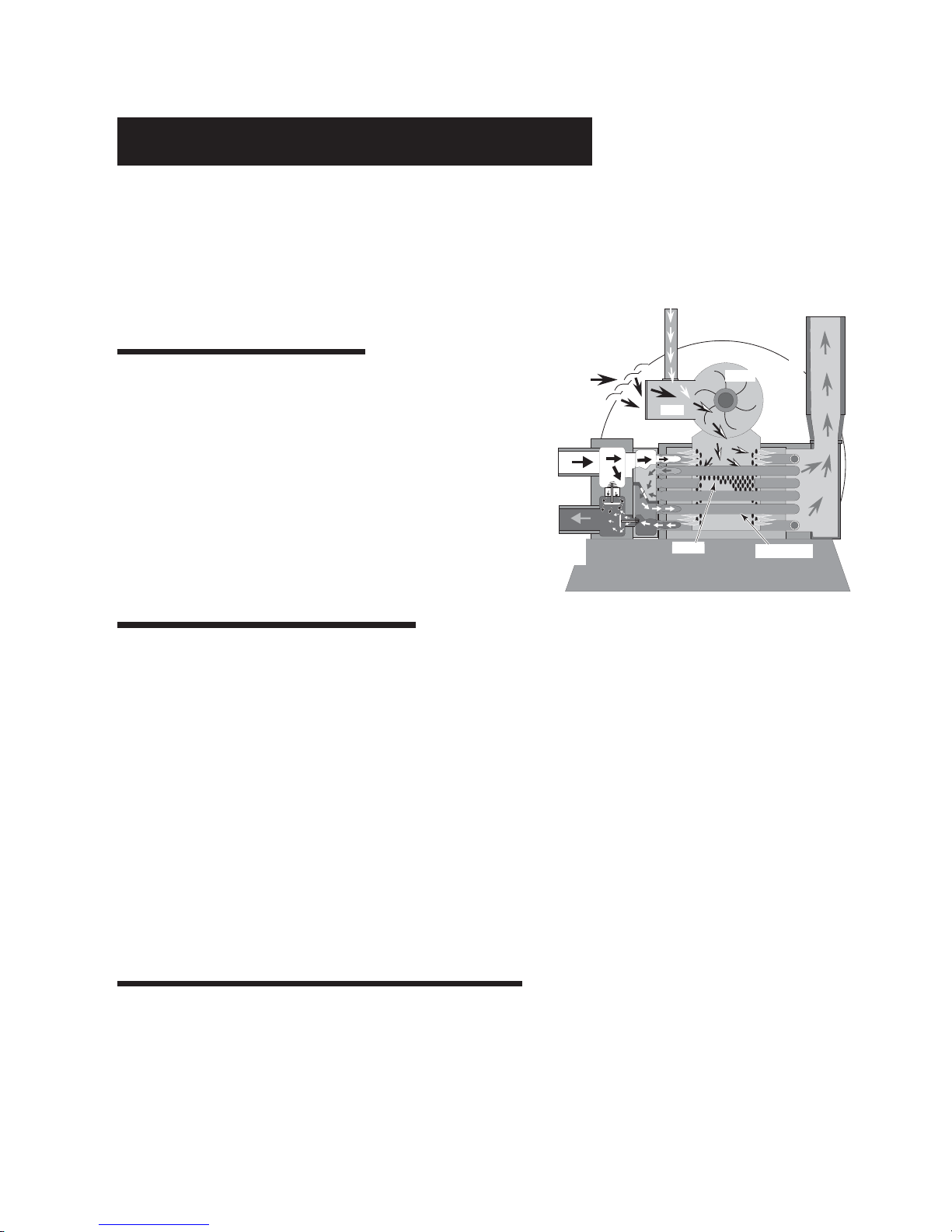

HeaterDescription................................................................................................................................................................................ 9

SequenceofOperation......................................................................................................................................................................... 9

Puttingthe HeaterintoService ............................................................................................................................................................ 9

Specifications ...................................................................................................................................................................................... 10

PlumbingConnections.......................................................................................................................................................................... 11

Valves .................................................................................................................................................................................................. 11

ManualBy-Pass .................................................................................................................................................................................. 11

Water Connections ............................................................................................................................................................................... 12

BelowPoolInstallation ......................................................................................................................................................................... 12

GasConnections ................................................................................................................................................................................. 13

Gas Pipe Sizing ................................................................................................................................................................................... 13

SedimentTrap/DripLeg ....................................................................................................................................................................... 13

Testing GasLeaks andGas Pressure .................................................................................................................................................. 14

GasPressureRequirements ................................................................................................................................................................ 14

OutdoorInstallation .............................................................................................................................................................................. 15

HeaterClearances................................................................................................................................................................................ 15

OutsideInstallationVentingGuidelines ................................................................................................................................................. 16

CorrosiveVaporsandPossibleCauses ................................................................................................................................................ 17

ControlPanelIndexing ......................................................................................................................................................................... 17

FinalInstallationCheck ........................................................................................................................................................................ 17

ElectricalConnections.......................................................................................................................................................................... 18

Fireman’sSwitchConnection/RemoteControlConnections.................................................................................................................. 19

MasterTempWiringDiagram................................................................................................................................................................. 20

ElectricalSchematicLadderDiagram ................................................................................................................................................... 21

Section 4. Operation............................................................................................................... 22

BasicSystemOperation ...................................................................................................................................................................... 22

HSI(Hot-SurfaceIgnition)Lighting/Operation ....................................................................................................................................... 22

OperatingInstructions .......................................................................................................................................................................... 23

To Turn Off Gas toAppliance............................................................................................................................................................... 23

SafetyControls .................................................................................................................................................................................... 24 - 26

Section 5. Troubleshooting ................................................................................................... 27

InitialTroubleshootingandTroubleshootingChart ................................................................................................................................. 27

HeaterWillNotFireTroubleshooting .................................................................................................................................................... 28- 31

LEDDiagnostics .................................................................................................................................................................................. 32- 33

Burner/HeatExchangerTroubleshooting ............................................................................................................................................ 34

Section 6. Maintenance.......................................................................................................... 35

CareandMaintenance.......................................................................................................................................................................... 35

PressureReliefValve........................................................................................................................................................................... 35

After Start-Up ...................................................................................................................................................................................... 36

Spring,FallandWinterOperation ......................................................................................................................................................... 36

MaintainingPoolTemperature ............................................................................................................................................................... 37

EnergySavingTips.............................................................................................................................................................................. 37

ChemicalBalance ................................................................................................................................................................................ 37 - 38

ReplacementParts .............................................................................................................................................................................. 39 - 43