Rev. D 27-06-11 P/N 474131

3

Contents

Section 1. Heater Identification Information (HIN) ............................................................. 4

Heater Data Rating Plate ..................................................................................... 4

Section 2. Introduction .......................................................................................................... 5

Important Notices ................................................................................................................................................................................. 5

Warranty Information ............................................................................................................................................................................ 5

Code Requirements .............................................................................................................................................................................. 6

Consumer Information and Safety Information ...................................................................................................................................... 6 - 8

General Specifications ......................................................................................................................................................................... 8

Section 3. Installation ............................................................................................................. 9

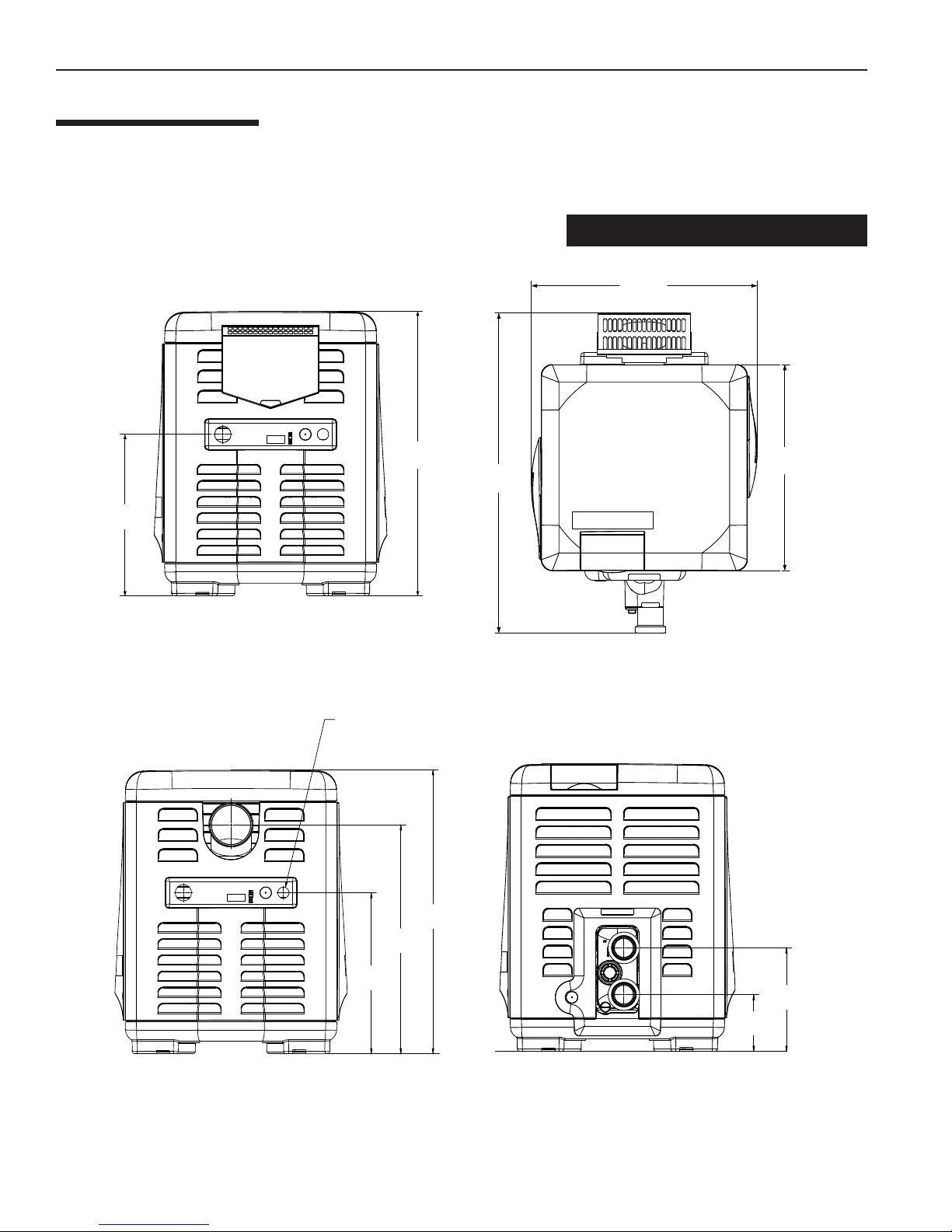

Heater Description ................................................................................................................................................................................ 9

Sequence of Operation ......................................................................................................................................................................... 9

Putting the Heater into Service ............................................................................................................................................................ 9

Specifications ...................................................................................................................................................................................... 10

Plumbing Connections .......................................................................................................................................................................... 11

Valves .................................................................................................................................................................................................. 11

Manual By-Pass .................................................................................................................................................................................. 11

Water Connections ............................................................................................................................................................................... 12

Below Pool Installation ......................................................................................................................................................................... 12

Gas Connections ................................................................................................................................................................................. 13

Gas Pipe Sizing ................................................................................................................................................................................... 13

Sediment Trap/Drip Leg ....................................................................................................................................................................... 13

Testing Gas Leaks and Gas Pressure .................................................................................................................................................. 14

Gas Pressure Requirements ................................................................................................................................................................ 14

Outdoor Installation / Heater Clearances .............................................................................................................................................. 15 - 16

Indoor Venting—General Requirements Heater Clearances / Outside Vent Removal ) .......................................................................... 17

Combustion Air Supply / Corrosive Vapors and Possible Causes ..................................................................................................... 18

Vent Installation (Indoor Installation or Outdoor Shelter) - Vertical Venting ........................................................................................ 18-21

Horizontal or Vertical Venting - Using Single-Wall Stainless Gas Vent ............................................................................................. 21

Connecting Single-Wall Stainless Steel Vent to the Heater .............................................................................................................. 22

Horizontal or Vertical Venting Flexible Duct (Flex-Vent) .................................................................................................................... 24

Corrosive Vapors and Possible Causes ................................................................................................................................................ 25

Control Panel Indexing ......................................................................................................................................................................... 25

Final Installation Check ........................................................................................................................................................................ 25

Electrical Connections .......................................................................................................................................................................... 26

Fireman’s Switch Connection/Remote Control Connections .................................................................................................................. 27

MasterTemp Wiring Diagram / Electrical Schematic Ladder Diagram .................................................................................................... 28 - 29

Section 4. Operation .............................................................................................................................................. 30

Basic System Operation / HSI (Hot-Surface Ignition) Lighting/Operation .............................................................................................. 30

Operating Instructions .......................................................................................................................................................................... 31

To Turn Off Gas to Appliance ............................................................................................................................................................... 31

Safety Controls (Air Flow Switch / Water Pressure Switch / Hight Limits / Operation of Ignitiion Module) ............................................ 32 - 33

Operating the Control Panel / Temperature Setting / Maximum Temperature Set Point ......................................................................... 33

Section 5. Troubleshooting ................................................................................................... 35

Initial Troubleshooting and Troubleshooting Chart ................................................................................................................................. 35

Heater Will Not Fire Troubleshooting (A, B, C, D) ................................................................................................................................ 36 - 39

LED Diagnostics (AGS, AFS, HLS, PS Thermistor) ............................................................................................................................ 40 - 41

Burner / Heat Exchanger Troubleshooting ............................................................................................................................................ 42

Section 6. Maintenance ..........................................................................................................43

Care and Maintenance .......................................................................................................................................................................... 43

Pressure Relief Valve ........................................................................................................................................................................... 43

After Start-Up ...................................................................................................................................................................................... 44

Spring, Fall (Autumn) and Winter Operation ........................................................................................................................................ 44

Maintaining Pool Temperature / Energy Saving Tips ............................................................................................................................. 45

Chemical Balance ................................................................................................................................................................................ 45 - 46

Replacement Parts .............................................................................................................................................................................. 47 - 51