Operator’s manual Pentruder®3P8 HF-wire saw and Pentpak - Original instructions 2

Operator’s manual for

Pentruder® 3P8 High Frequency Wire Saw and

Pentpak®high frequency power pack

Version: 7 Date: 2019-02-19

Support & Service document

Original instructions

Copyright © 1997-2019 Tractive AB.

Pentruder and Pentpak are registered trademarks belonging to Tractive AB.

Contents

1Introduction .............................................................................................................................. 3

Validity of this operator’s manual................................................................................................... 3

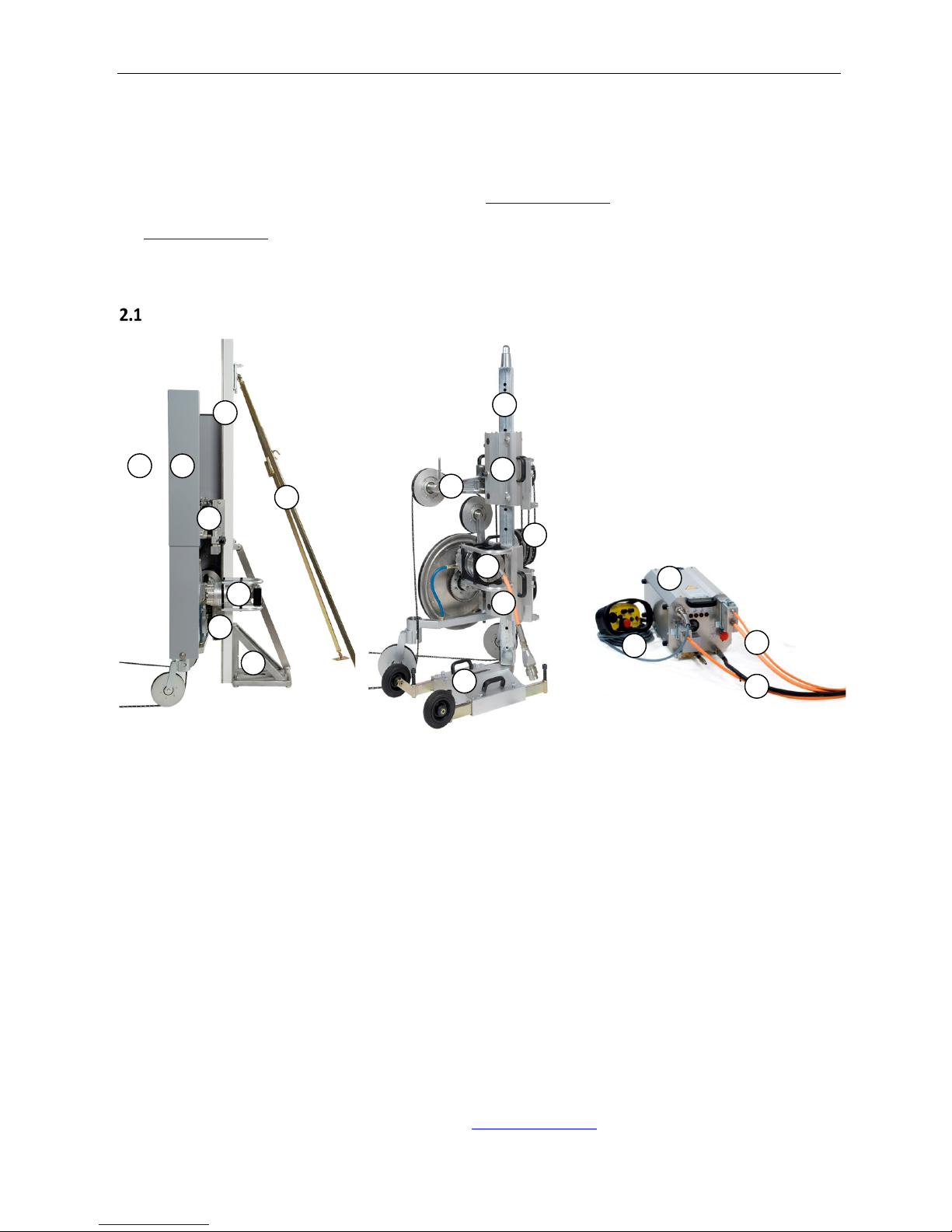

2Description of the machine ....................................................................................................... 4

List of complete machine................................................................................................................ 4

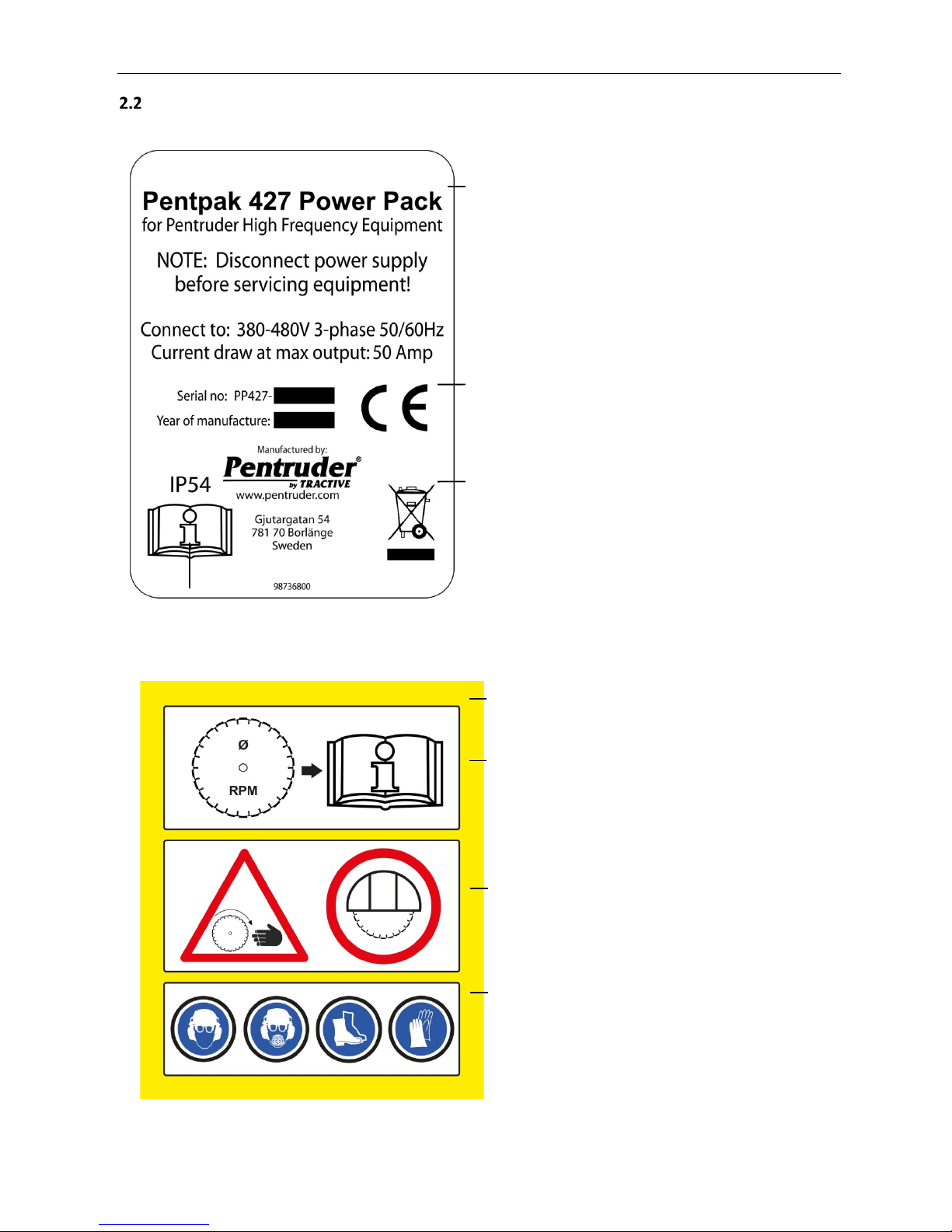

Signs and data plates on the machine............................................................................................. 5

3Safety instructions .................................................................................................................... 6

Safety instructions which are used in this operator’s manual.......................................................... 6

Intended use of the machine .......................................................................................................... 6

General safety instructions............................................................................................................. 7

Safety precautions at site ............................................................................................................... 8

4Preparations and mounting .................................................................................................... 11

Advice about the positioning of the Pentruder 3P8 wire saw........................................................ 11

Mounting the base plate .............................................................................................................. 11

Mounting 3P8 HF-wire saw with column system with cone coupling ............................................ 12

Mounting 3P8 HF-wire saw with with TS track ............................................................................. 16

Mounting the 3P8 wire saw modules............................................................................................ 21

Assembly of HF-motor, cords and hoses ....................................................................................... 24

Attach guards ............................................................................................................................... 25

Preparing the power pack............................................................................................................. 26

5Cutting.................................................................................................................................... 31

Preparations before starting to cut............................................................................................... 31

5.2 Starting the HF-machine ............................................................................................................... 32

6Troubleshooting...................................................................................................................... 38

Check list...................................................................................................................................... 38

LED type warning lights on the power pack .................................................................................. 39

7Maintenance........................................................................................................................... 42

Every day / week maintenance..................................................................................................... 42

Maintenance which should be performed by Pentruder authorized technician............................. 44

Transport and storage of the machine .......................................................................................... 44

8Technical Data Pentruder Modular Rig System ....................................................................... 45

Declaration of conformity ............................................................................................................. 46

Technical Director.......................................................................................................................... 46

Installation Certificate................................................................................................................... 47

Appendix for Wireless Remote Control: Hectronic User’s Manual