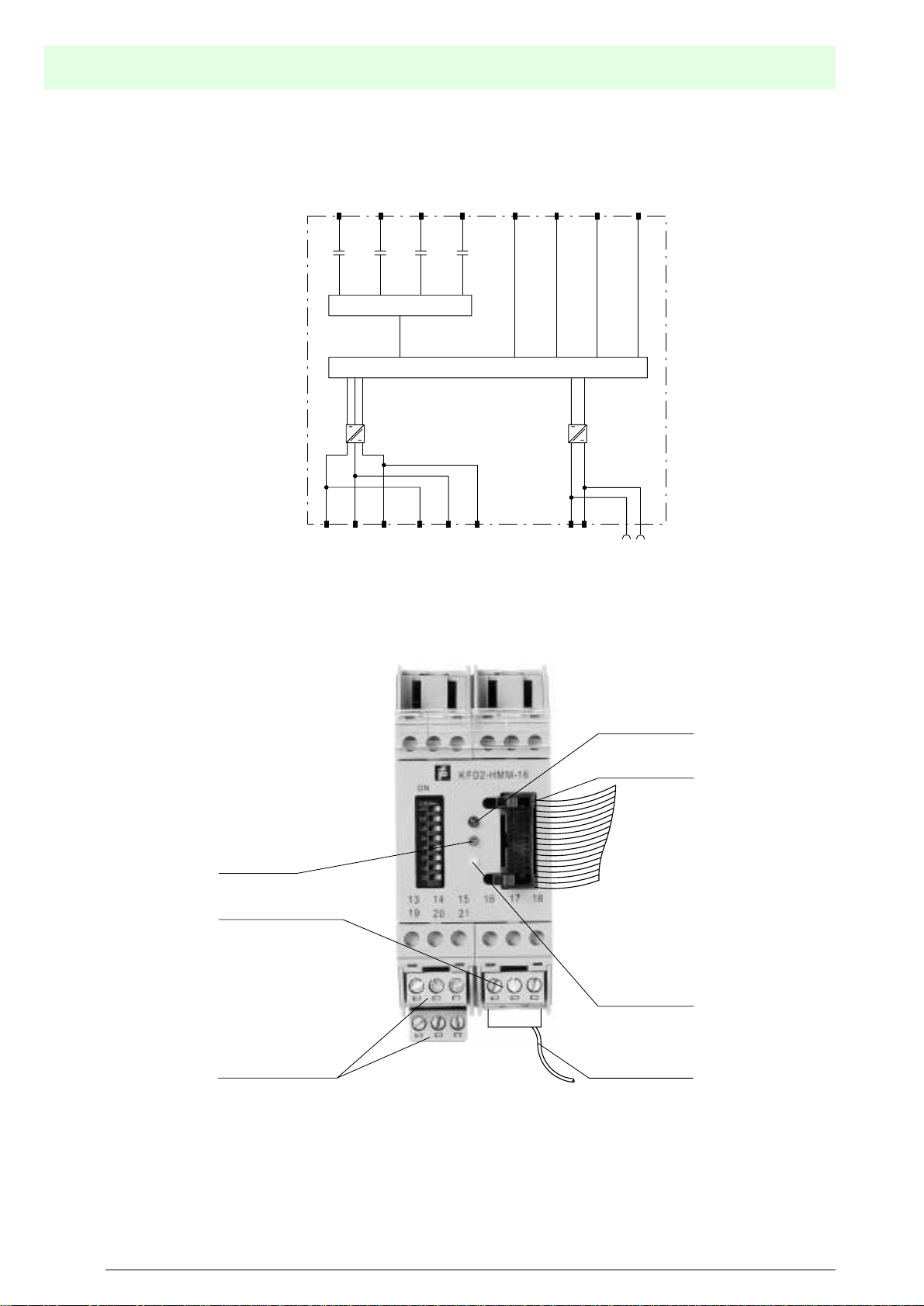

HART Multiplexer Master KFD2-HMM-16

Product description

10 Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group •Tel.: Germany (06 21) 7 76-0 •USA (330) 4 25 35 55 •Singapore 7 79 90 91 •Internet http://www.pepperl-fuchs.com

Part No.: 109143, Date of issue 29.11.2000

Interface

In this way, the multiplexer master acts as a transparent gateway between the service station (typically a

PC with suitable software, see section 2.3.2) and the field devices. The service station is able to communi-

cate with up to 31 multiplexer master via up to 38400 baud R S485 connection. Because each master is

able to communicate with 256 field devices, up to 7936 field devices are controlable over a singl e RS485

interface.

HART

As a digital communication system for servicing and configuration purposes, the HART protocol is suppor-

ted by many field devices with conventional analogu e 4m A. . .2 0mA current loops. The HART signal is

thus modulated on the analogue current as an FSK signal (see section 2.2). The modulator/demodulator

circuitry (Modem) required for this is integrated in the multiplexer. Only one HART transmitter can be con-

nected at each multiplexer HART connection (no "multidrop“functionality).

Special procedures in respect to HART communication:

•On the host side (RS 485) always the long frame address is used (except for command 0).

•On the field devices side, either the short address or the long frame address is used, depending on

necessity.

•The operating modes "Primary Master“and "Secondary Master" and the corresponding time responses

are supported on the field device side.

•On the host side, only the commands 0 ... 3 and 1 1. . .13 are accepted from the secondary host. Other

commands are not accepted/are ignored.

•Commands to connected field devices are only accepted by the primary host.

•Extended messages and messages in the Burst Mode are recognised and used, but not generated by

the multiplexer itself.

•An answer buffer is available for a delayed message response. This can be used to intermediately store

a message, the command for which requires a long execution time.

Loop construction/REBUILD (Software function)

On power-up, the device searches the multiplexers in the multiplexer table for the connected HART field

devices (commands 0 and 41) and generates the internally required access tables. This function can also

be carried out by the connected service station, as is necessary, for example, in communication with newly

connected HART field devices. The duration of this function depends on the number of connected multiple-

xer slaves and HART field devices and also on the type of loop search (see command 153) and the permis-

sible number of message repeats. With 16 HART devices (e.g. by using only one master without slaves) the

duration is between 1 5s and 3 0s. The number of permissible message repeats is set to "2" in the factory

setting and the loop search type to "single analogue".

During the REBUILD phase, only certain read commands are accepted from the service station (commands

0, 1, 2, 3, 11, 12, 13, 48, and 129). All other commands are followed by the response "Busy" (Code 32, see

section 5.3.2), until the REBUILD phase ends.

Cyclic data interrogation/SCAN (software function)

The multiplexer can read cyclic data from up to 31 transmitters. In this case the SCAN option must be set

for the transmitter (command 137) and the SCAN function activated in the multiplexer (command 149,

function 1). Which data is transferred is determined by the "SCAN command" option (command 147).

If the SCAN function is activated, the transmitters, on which the SCAN option is activated are regularly chek-

ked for data. In this case, the SCAN command is executed, with which one or more variables are read from

the transmitter. If a field device does not respond, it is designated as having "disappeared" (see command

129), but it remains in the search list (i. e., it is searched for again on the next run sequence). If a device

has disappeared, but responds correctly on the next search command, it is then listed as "appeared". If,

instead of this, another device has answered, then the status "mismatched" is assigned.

1. Command 4 is additionally used on transmitters which only support the old HART specifications up to 4.