2019-02

10

Functional Safety M-LB-(Ex-)2000-System

Planning

3.2 Assumptions

The following assumptions have been made during the FMEDA:

• The device will be used under average industrial ambient conditions comparable

to the classification "stationary mounted" according to MIL-HDBK-217F.

Alternatively, operating stress conditions typical of an industrial field environment

similar to IEC/EN 60654-1 Class C with an average temperature over a long period

of time of 40 ºC may be assumed. For a higher average temperature of 60 ºC,

the failure rates must be multiplied by a factor of 2.5 based on experience.

A similar factor must be used if frequent temperature fluctuations are expected.

• The control loop is considered to be either isolated from ground (except i. e. components

within the protection module), or one of the protected lines is directly connected to ground.

In both cases, a failure mode leads to a safe reaction or has no effect, so the worst case

is assumed to be a no effect failure.

• Failure rate based on the Siemens standard SN 29500.

• Failure rates are constant, wear is not considered.

• The control loop has a hardware fault tolerance of 0and it is a type Adevice.

A SFF value for this device is not given, since this value has to be calculated in conjunction

with the connected field device, as described in the following section.

• The devices M-LB-(Ex-)2114(.SP) do not withstand conducted RF immunity tests

(10 V according to IEC/EN 61000-4-6).

The devices M-LB-(Ex-)2114(.SP) and M-LB-(Ex-)2144(.SP) do not withstand immunity

tests against conducted common mode disturbances at spot frequencies

(100 V according to IEC/EN 61000-4-16).

Cause is that the limit values of the protective elements for the application

are lower than the test limits required by the standards. The user has to decide whether

the devices are suitable for the application or whether the devices with higher voltage limits

must be used.

Application

The surge protection barrier and the connected device (transmitter, isolator or actuator)

have to be considered in combination. The PFDavg/PFH budget of the device categories

in the entire safety loop is:

• Actuator (valve) 40 %

• Transmitter (sensor) 25 %

• Isolator 10 %

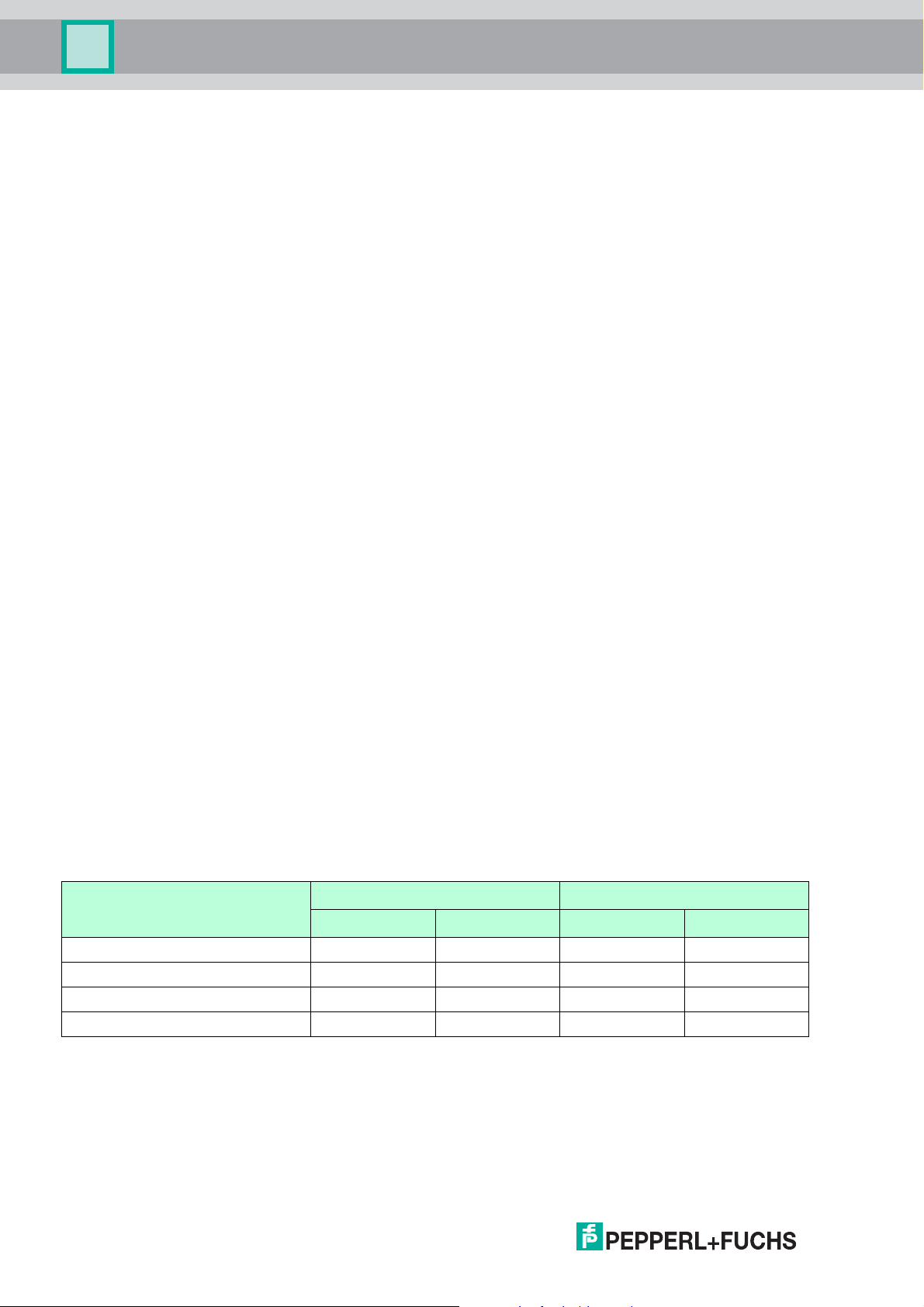

As an overview for the SIL2 or SIL3 safety loop this means:

Device category SIL2 SIL3

PFH PFDavg PFH PFDavg

Total 10-6 10-2 10-7 10-3

Actuator (40 %) 4 x 10-7 4 x 10-3 4 x 10-8 4 x 10-4

Transmitter (25 %) 2.5 x 10-7 2.5 x 10-3 2.5 x 10-8 2.5 x 10-4

Isolator (10 %) 10-7 10-3 10-8 10-4

Table 3.1 Overview PFDavg/PFH budget