switch, still typically both signal and idle pins are in

the center.

4. Add the alligator clips and connect the RED

clip to the sensors POWER pin.

5. Connect the BLACK clip to the sensors

GROUND pin.

6. Turn meters range selector to 20K

Ω

range.

7. View and record the reading displayed.

The results should show a small amount of

resistance. If the meter shows over range the

circuit is open and the sensor is defective.

8. Move the RED alligator clip to the sensors

SIGNAL pin.

9. Find the linkage on the Throttle Position Sensor,

manually move the throttle linkage cycling from

closed to fully open.

10. Watch the meter display, the reading will either

increase or decrease resistance.

Some throttle position sensors include a WOT, Wide

Open Throttle switch. These switches are tested like

the other switches in the Fuse/Switch section.

11.

Find the vane on the Vane Air Flow Sensor,

typically on or near the multiport electronic fuel injector.

12. Slowly open the butterfly valve from closed to

open by pushing on it. This is the normal function of

the valve and will not harm the sensor.

13. Watch the meter display, the reading will either

increase or decrease resistance.

Some vane air flow sensors have an idle switch and

an intake air temperature sensor in addition to a

potentiometer. If so equipped these switches are

tested like the other switches in the Fuse/Switch

section.Refer to vehicle service manual for

recommended resistance outputs.

EGR Valve Position Sensor

1. Find the vacuum port on the EGR Valve

Position Sensor.

2. Remove the vacuum hose from EGR valve.

3. Connect a hand vacuum pump (W87030) to the

EGR valve.

4. Add the alligator clips and connect the RED

clip to the sensors signal pin (typically the center).

5.

Connect the BLACK clip to a good body GROUND.

6.

Slowly apply vacuum to the EGR valve. Typically,

6 - 10 inches of Hg. should fully open the valve.

7.

Watch the meter display, the reading will either

increase or decrease resistance. Refer to vehicle

service manual for recommended resistance outputs.

• A good sensor should show an increase or

decrease in the resistance as the sensor is opened

and closed.

• A bad sensor will have no change in resistance.

ENGINE SENSORS TESTS CONT.

MAF vs MAP

Manifold Absolute Pressure (MAP) is a sensor to

measure vacuum, the computer calculates the

engine air flow based on the vacuum, throttle

position, and intake air temperature.

Mass Air Flow (MAF) is a sensor that measures the

actual air flow going into the engine

MAP/BARO Sensors

These sensors send signals to the ECU indicating

atmospheric pressure and/or engine vacuum. There

are two different types of MAP sensors. The first,

depending on the vehicle manufacturer may be a

frequency generator used by Ford. The other type

MAP may send a DC voltage signal to the ECU.

This is the most common used by Honda, Toyota,

Honda, GM etc. Refer to your vehicle service

manual for the type MAP sensor your vehicle uses.

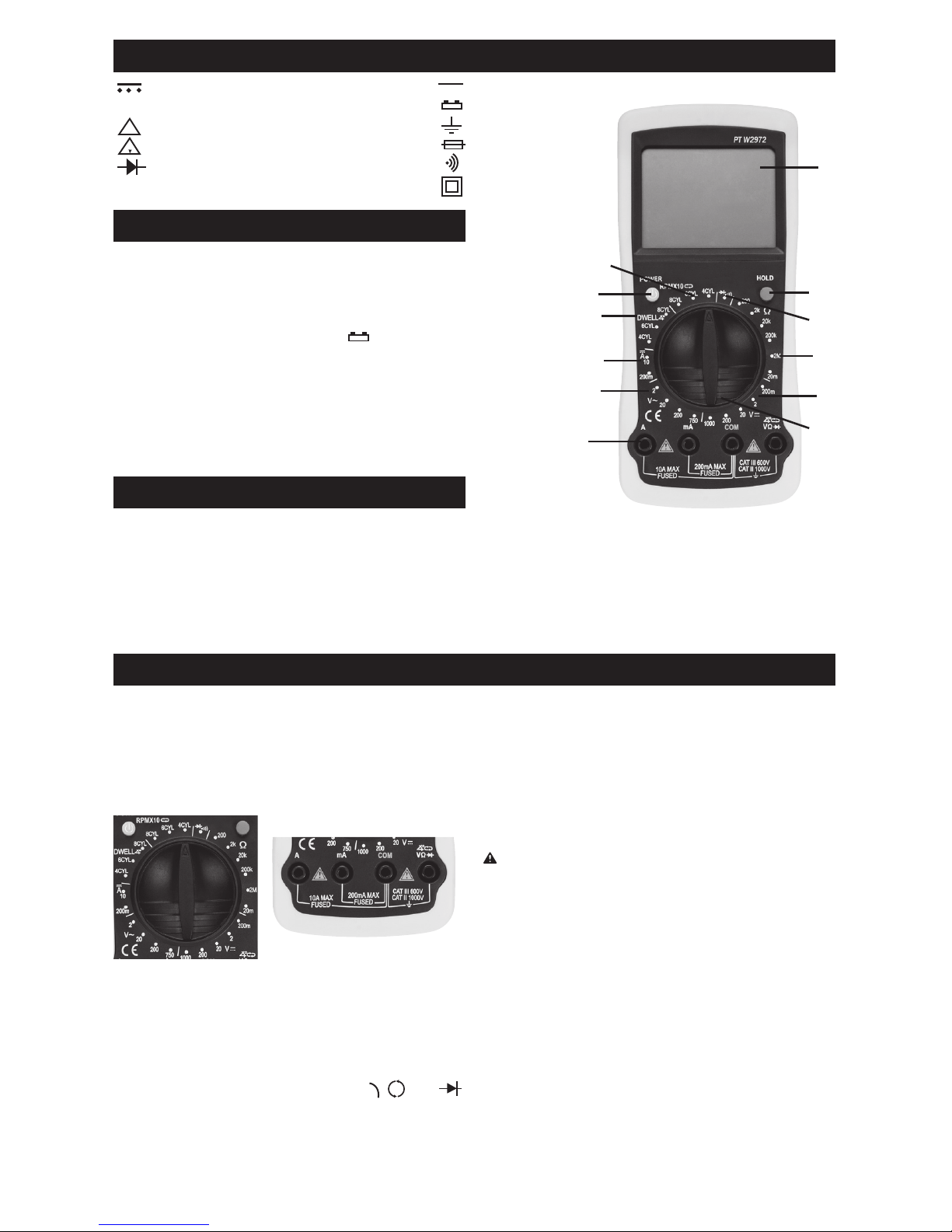

1. Insert BLACK test lead into COM test lead jack.

2.

Insert RED test lead into

test lead jack.

3. For this test you’ll need to back probe or add

jumper leads from the A and C pin in the harness. If

adding jump leads disconnect the MAP from the

wiring harness and the vacuum line from the sensor.

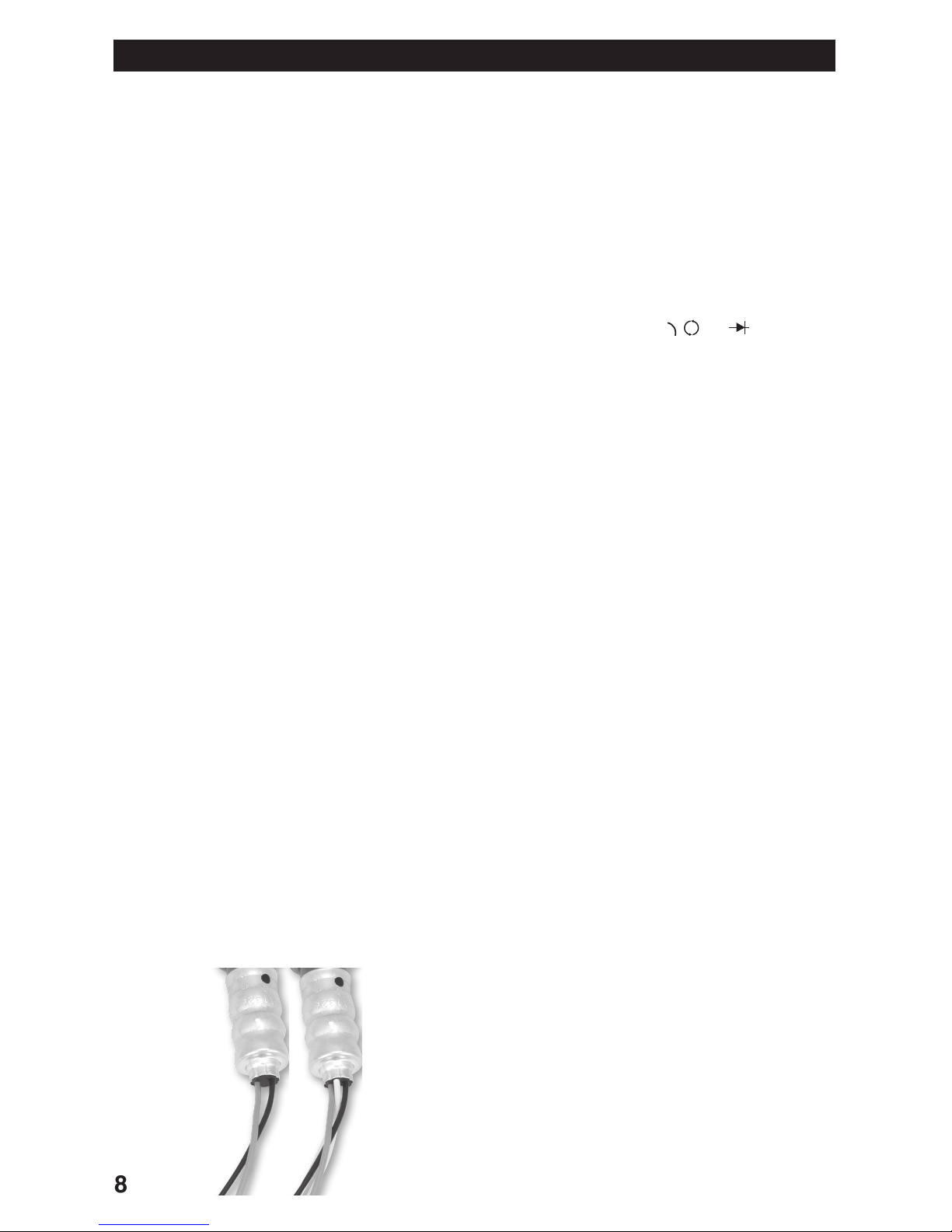

Special back probe lead attachments are available

from most electronic stores (not included).

4. Connect a hand held vacuum pump to vacuum

port on MAP sensor, our model W87030.

5. Identify the A, B, and C pin/wire location on the

MAP harness connection. Connect a jumper wire

between Pin A on wiring harness and sensor.

6. Connect another jumper wire between Pin C

on wiring harness and sensor.

7. Add the alligator clips and connect RED clip to

lead to sensor Pin B.

8.

Connect the BLACK clip to a good vehicle

body ground.

Jumper leads/back probes should be

isolated so they can’t touch each other.

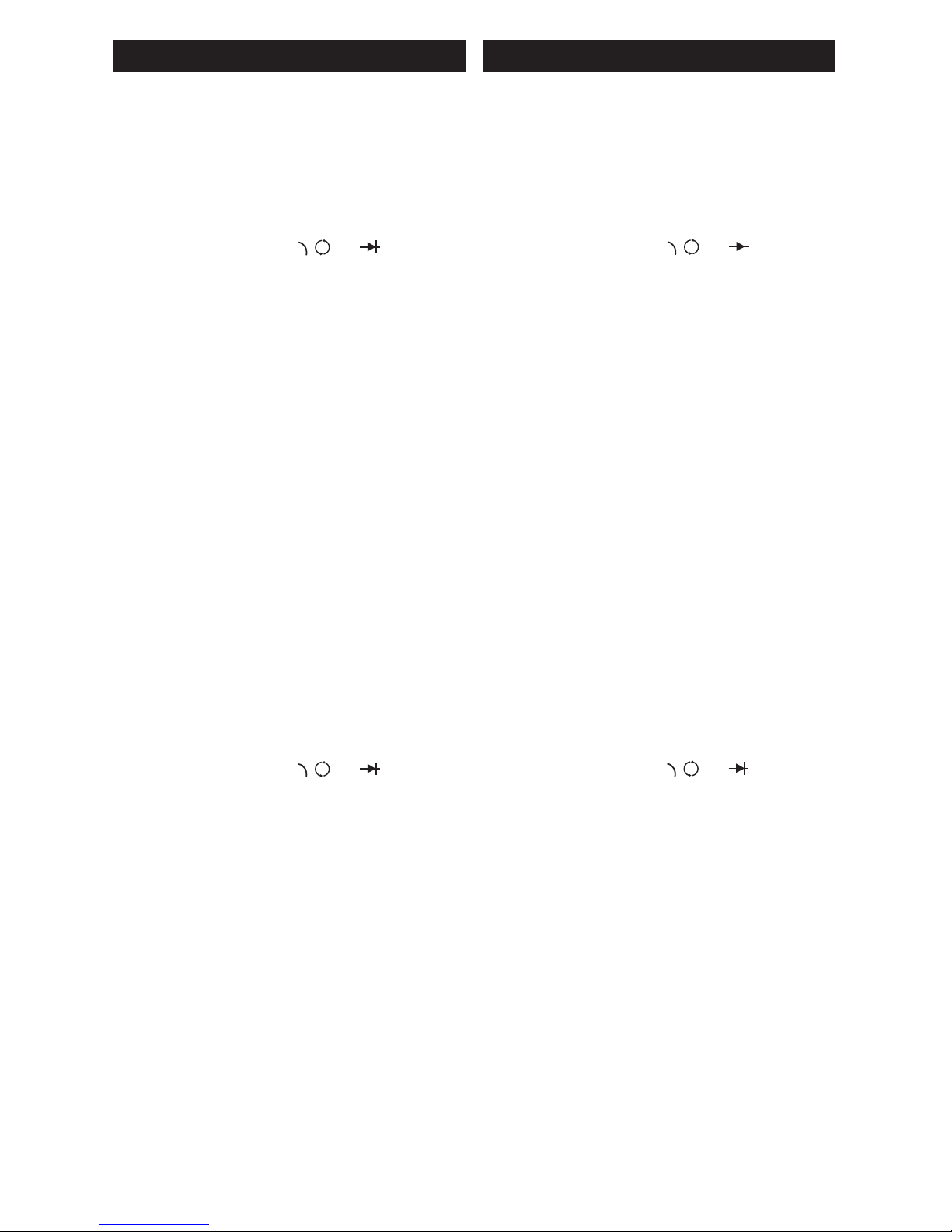

9. Turn the Ignition to the ON position but do not

start the engine.

10.

Turn the meters range selector to 20V DC range

for DC signals, and 4CYL for Frequency signals.

11. With vacuum at 0 in. Hg. your DC volts should

be approximately 3V or 5V. With a Frequency MAP,

when testing a Ford, your display reading should be

between 4532 to 5021 RPM’s, (Display RPM x 10)

For other frequency type MAP sensors refer to your

vehicle service manual for MAP sensor specifications.

12. With the Vacuum pump attached to the MAP

slowly apply vacuum. Do not exceed 20 in. Hg or

you’ll damage the MAP sensor. Voltage and RPM

readings should decrease as vacuum increases.

Refer to your vehicle service manual for voltage and

frequency drops to increasing engine vacuum.

Ʊ

Ⅴ

Ʌ

°

7