2

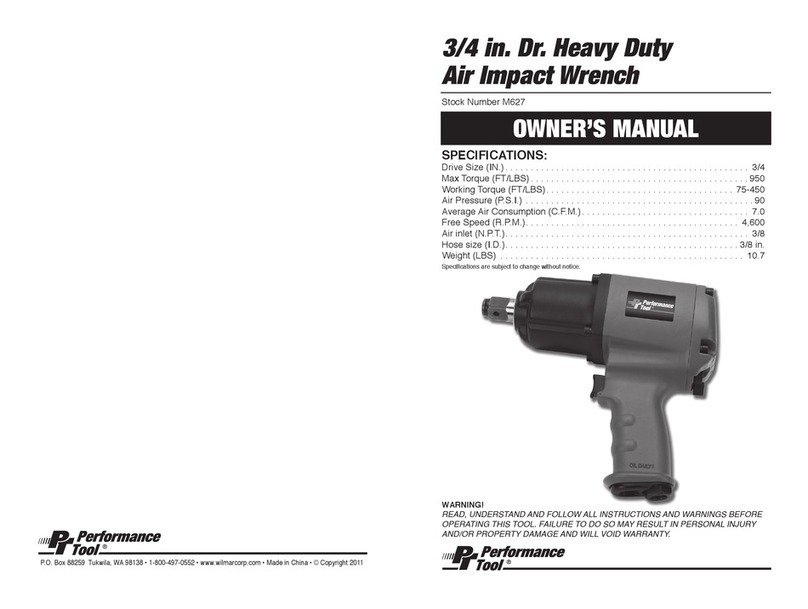

SPECIFICATIONS

Specifications are

subject to change

without notice.

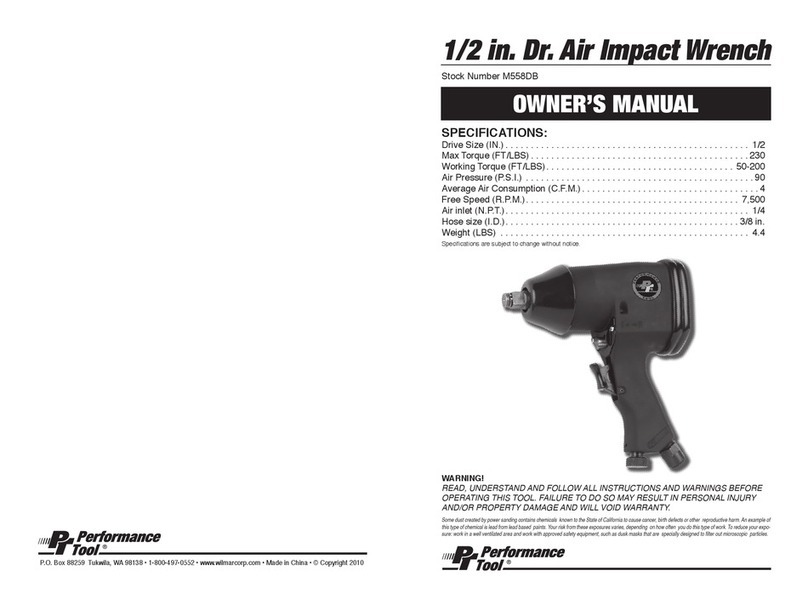

Square Drive: ........................................... 1/2 in.

Max. Torque (FT/LBS): .................................230

Working Torque (FT/LBS): ..................... 50-200

Air Pressure (PSI):..........................................90

Avg. Air Consumption (CFM): .........................7

Free Speed (RPM).......................................7800

Air Inlet (NPT): ......................................... 1/4 in.

Hose Size (ID): ......................................... 3/8 in.

Specifications are subject to change without notice.

SAFETY GUIDELINES / DEFINITIONS

UNPACKING AND INSPECTION

WARNING: Read and understand this entire instruction manual before attempting to assemble,

install, operate or maintain this product. Failure to comply with the instructions may result in serious

personal injury and/or property damage! The following signal words are used to emphasize safety warn-

ings that must be followed when using this product:

This instruction manual is intended for your benefit. Please read and follow the safety, installation,

maintenance and troubleshooting steps described within to ensure your safety and satisfaction. The contents

of this instruction manual are based upon the latest product information available at the time of publication.

The manufacturer reserves the right to make product changes at any time without notice.

DANGER Indicates an imminently hazardous

situation that, if not avoided, WILL result in

death or serious injury.

WARNING Indicates a potentially hazardous

situation that, if not avoided, COULD result in

death or serious injury.

CAUTION Indicates a potentially hazardous

situation that, if not avoided, MAY result in

minor or moderate injury.

NOTICE Indicates important information,

which if not followed, MAY cause damage to

equipment.

After opening the carton, unpack your new product and related parts & accessories. Please inspect it

carefully for any damage that may have occurred during transit. Please check it against the photograph

on carton. If any parts are missing, please call customer service at 1-800-426-1262 between 6 a.m. and 5

p.m. Pacific time.

WARNING: DO NOT operate this product if damaged during shipment, handling or misuse. Do not

operate the product until the parts have been replaced or the fault rectified. Failure to do so may result in

serious personal injury or property damage. All damaged parts must be repaired or replaced as needed

prior to operating this product. Check to see that all nuts, bolts and fittings are secure before putting this

product into service. If you have any questions, or require assistance with damaged or missing parts,

please contact our factory customer service department at: 1-800-426-1262. Please have the serial

number, model number, and date of purchase available for reference when calling.

WARNING: Some dust created by power sanding contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive harm. An example of this

type of chemical is

-lead from lead based paints,

-Crystalline Silica from bricks and cement or other masonry,

-Arsenic and Chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure: work in a well ventilated area and work with approved safety equip-

ment, such as dusk masks that are specially designed to lter out microscopic particles.