1. To set the tool to desired torque, select a nut or screw of known tightness of the same

size, thread pitch and thread condition as those on the job.

2. Turn air regulator to low position, apply wrench to nut and gradually increase power (turn

regulator to admit more air) until nut moves slightly in the direction it was originally set.

The tool is now set to duplicate that tightness, note regulator setting for future use.

3. When tightening nuts not requiring critical torque values, run nut up flush and then

tighten an additional one quarter to one-half turn (slight additional turning is necessary if

gasket are being clamped).

4. For additional power needed on

disassembly work, turn regulator to its

fully open position. This impact wrench

is rated at 5/8 USS bolt size. Rating

must be down graded for spring U

bolts, tie bolts, long cap screws,

double depth nuts, badly rusted

conditions and spring fasteners as

they absorb much of the impact power.

When possible, clamp or wedge the

bolt to prevent spring back.

5. Soak rusted nuts in penetrating oil and

break rust seal before removing with

impact wrench. If nut does not start to

move in three to five seconds use a

larger size impact wrench. Do not use

impact wrench beyond rated capacity

as this will drastically reduce tool life.

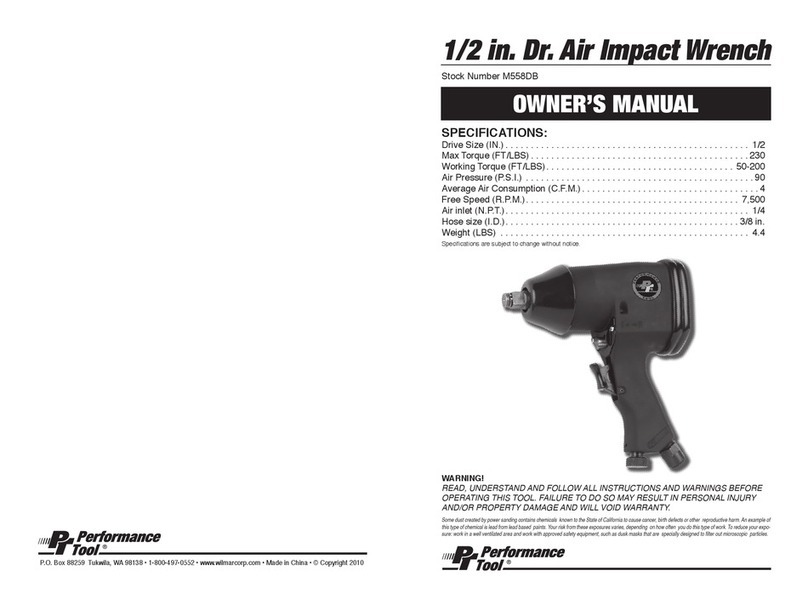

Oil tool before each use. 4 to 5 drops of a good grade Air Tool Oil placed in the air inlet is

sufficient. Use proper air pressure and CFM rating listed for this tool.

Drain water from hoses and compressor tank. Water in the air supply line will cause

gumming and loss of power. Clean the air filter on the supply line and flush the tool with

gum solvent or a 50/50 mix of air tool oil and kerosene. It may be necessary to

disassemble the tool to properly clean and re-lubricate.

LUBRICATION & MAINTENANCE

Motor

Oil

Trans.

Fluid

Brake

Fluid

Water

Whip

hose

Air Tool

Oil

YesNo

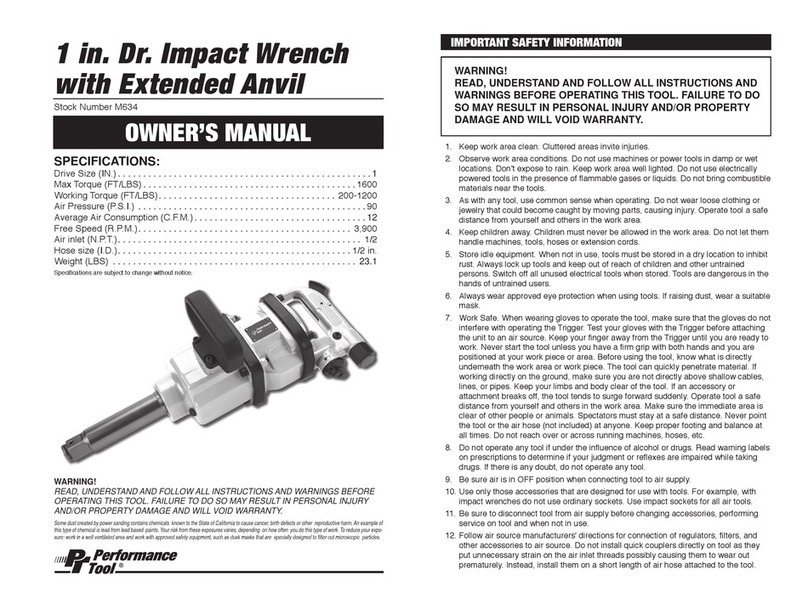

IMPORTANT SAFETY INFORMATION

ASSEMBLY / INSTALLATION

1. You will need to prepare the 1/4" Quick-disconnect Coupler Plug to connect to the air

inlet on the impact wrench. Wrap the Coupler Plug with pipe thread seal tape before

threading it into the Air Inlet. Connect the a Quick-Disconnect coupler on a 3/8 in. ID Air

Source Hose to the tool.

Note: If you are not using an automatic oiler system, before operation, add a few drops of

Pneumatic Tool Oil to the airline connection. Add a few drops more after each hour of

continual use.

2. Set the air pressure on your compressor to 90 PSI. Do not exceed the recommended air

pressure of 90 PSI.

3. Check the air connection for leaks. Once you are satisfied there are no leaks, turn off the

air compressor and disconnect the tool.

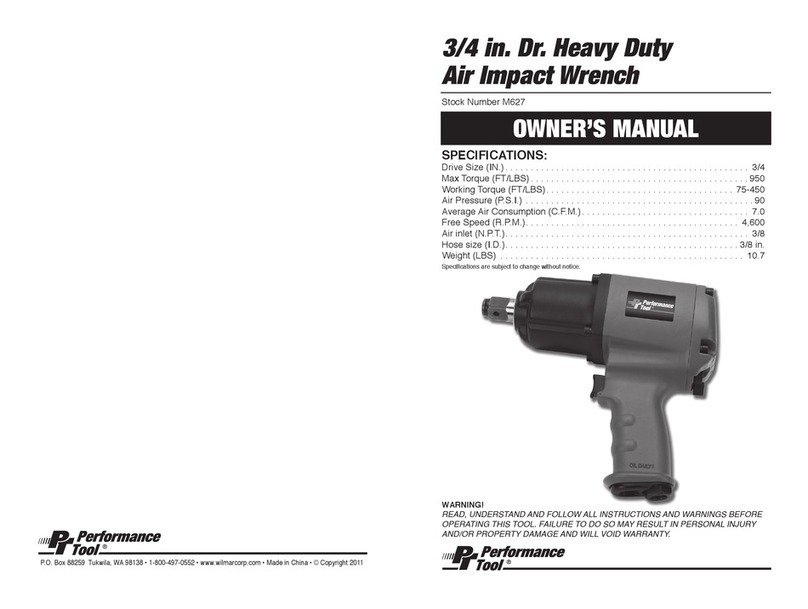

Clean air of correct air pressure is recommended for the power supply for this tool. A

maximum of 90 PSI at the tool is recommended for most air tools of this class. Check

specifications section for recommended pressure. (Depending on length of air hose and

other circumstances, air pressure at compressor may need to be increased to 100 PSI to

ensure 90 PSI at the tool.)

Water in the air hose and compressor tank contributes to reduced performance and

damage of the air tool. Drain the air tank and filters before each use and as necessary to

keep the air supply dry.

Hose length over 25 ft. causes loss in line pressure. Increase hose I.D. or increase

compressor pressure to compensate for the pressure loss. Use an in-line pressure

regulator with gauge if air inlet pressure is critical.

AIR SOURCE

13. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any

part that is damaged should be properly repaired or replaced by a qualified technician.

14. Maintenance. For your safety, maintenance should be performed regularly by a

qualified technician using original PERFORMANCE TOOLS® replacement parts.

Failure to do so can lead to accidents for the operator. Use of any other parts will void

the warranty. Only use accessories intended for use with this tool. Approved

accessories are available from Performance Tool®. Use only accessories that are

recommended by the manufacturer for your model. Accessories that may be suitable

for one tool may become hazardous when used on another tool.

WARNING: Repetitive motions or exposure to vibration may be harmful to your hands and arms.

WARNING: This product and its packaging contain a chemical known to the State of California

to cause cancer, birth defects, or other reproductive harm.

WARNING: The warnings, cautions, and instructions discussed in this instruction manual cannot

cover all possible conditions and situations that may occur. It must be understood by the

operator that common sense and caution are factors which cannot be built into this product, but

must be supplied by the operator. Read and understand all of the instructions provided in the

instruction manual of this product, as well as, any other tool (s) used with this product.

OPERATION

Air Inlet

Air

Regulator

Trigger