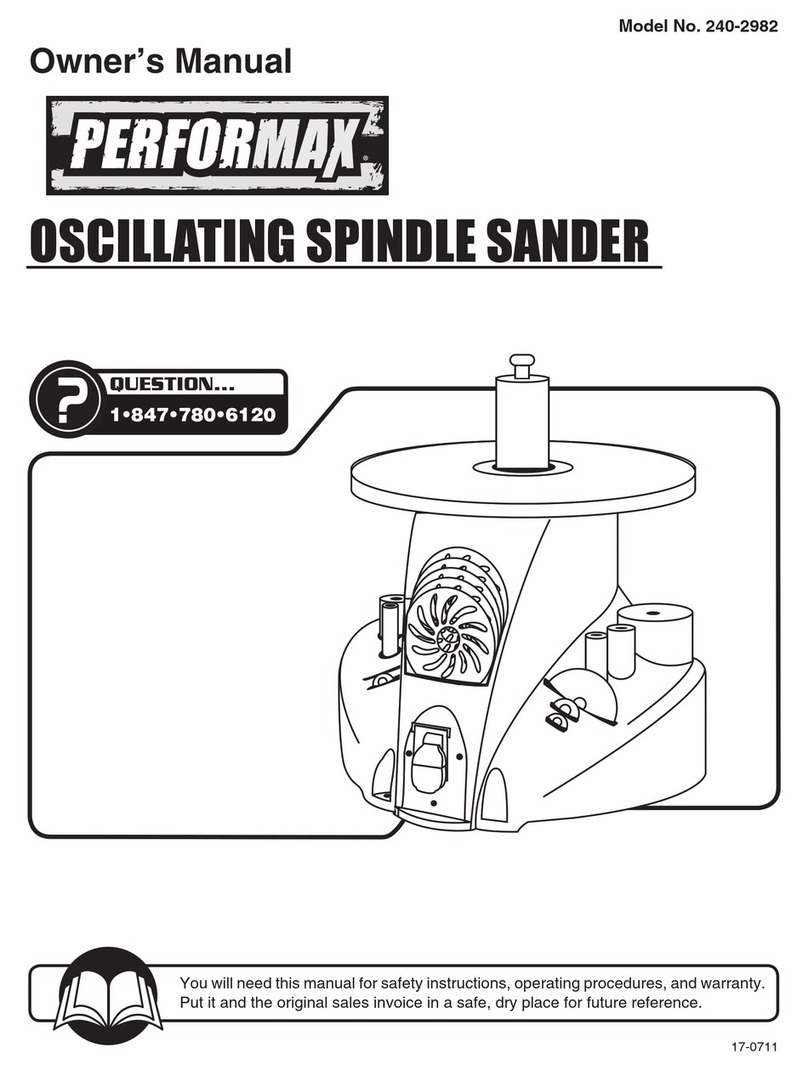

Specific safety rules for the spindle sander

WARNING: Do not operate the spindle sander until it is fully assembled and you

have read and understood the following instructions and the warning labels on the

spindle sander.

1. Know the condition of the spindle sander. If any part is missing, bent, or does not operate

properly, replace the part before using the sander.

2. Determine the type of work you are going to be doing before operating the spindle sander.

3. Secure your work. Support the workpiece securely on the table, and hold it with both hands.

4. Be aware of the direction of feed. Feed the workpiece into the sanding sleeve against the

direction of rotation of the sanding sleeve.

5. Always keep your hands out of the path of the sander and away from the sanding sleeves.

Avoid hand positions where a sudden slip could cause your hand to move into the spindle. Do

not reach underneath the workpiece or around the sanding sleeve while the spindle is rotating.

6. Disconnect the sander after turning off the power switch. Wait for the spindle to stop rotating

before performing maintenance. The sander must be disconnected when not in use or when

changing accessories, sanding sleeves, rubber spindles, or other items.

7. Make sure there are no nails or other foreign objects in the area of the workpiece to be sanded.

8. Never use this sander for wet sanding. Failure to comply may result in electric shock causing

serious injury or worse.

9. Use only identical replacement parts when servicing this spindle sander.

10. Make sure the spindle has come to a complete stop before touching the workpiece.

11. Take precautions when sanding painted surfaces. Sanding lead-based paint is NOT

RECOMMENDED. The contaminated dust is too difficult to control, and could cause lead

poisoning. When sanding paint:

Protect your lungs. Wear a dust mask or respirator.

Do not allow children or pregnant women in the work area until the paint sanding job is

finished and the clean-up is completed.

Do not eat, drink, or smoke in an area where painted surfaces are being sanded.

Use a dust collection system when possible. Seal the work area with plastic. Do not track paint

dust outside of the work area.

Thoroughly clean the area when the paint sanding project is completed.