PERLICK RESIDENTIAL INSTALLATION MANUAL FOR BEER DISPENSING EQUIPMENT

2 | perlick.com/residential

CONGRATULATIONS

Congratulaons on your purchase of a Perlick high quality

residenal Beer Dispenser. Perlick has proudly manufactured

beer dispensing systems for over 50 years for bars, restaurants,

stadiums, arenas and large venues around the world. That same

technology is used in each and every residenal beer dispenser

we produce, assuring you’ll pour fresh, cold beer as the brewery

intended it to be enjoyed.

All Perlick products are built with commercial grade stainless

steel, providing you with the beauty and durability for a lifeme

of use. This installaon guide will show you how to properly

install the dispensing equipment on your Perlick Beer Dispenser.

We dedicate considerable me to ensure that our products

provide the highest level of customer sasfacon. If, however,

service is required, call Perlick at 800.558.5592. For your own

protecon, never return merchandise for credit without our

approval.

We thank you again for selecng a high quality Perlick Beer

Dispenser. Cheers!

C

US

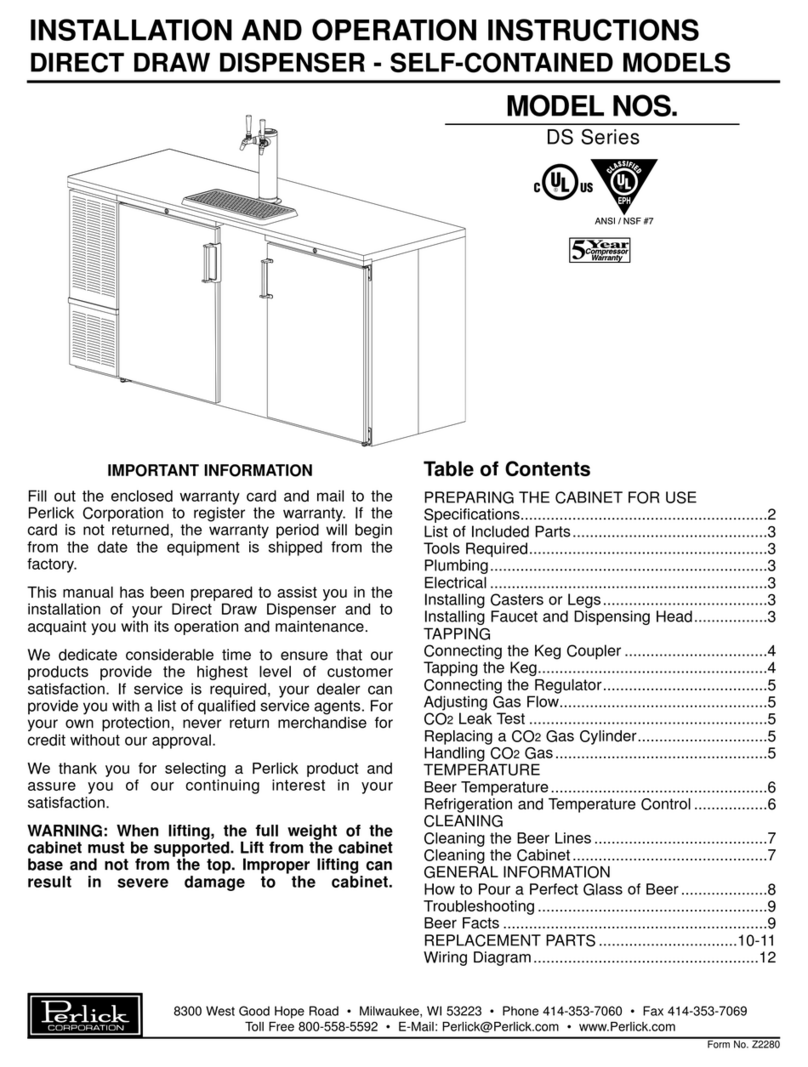

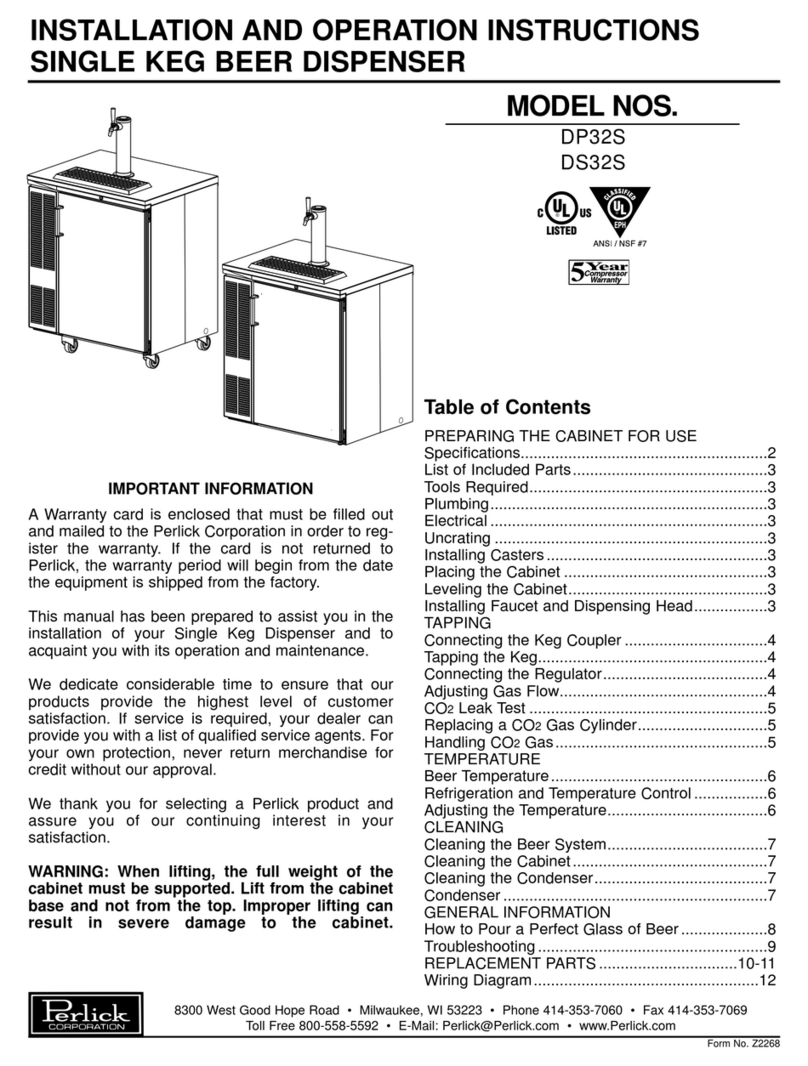

IMPORTANT!

The installation of the actual beer dispenser

cabinet should happen prior to installing

the dispensing equipment. Refer to the

Installation Manual that accompanied the

Beer Dispenser for step-by-step installation

of the cabinet.

Keep CO2 cylinder away from heat. Rupture

disc vents at 122°F maximum.

Allow only properly trained and experienced

personnel to handle high pressure gas.

Do not drop or throw regulator or CO2

cylinder.

Do not apply oil to the regulator!

PLEASE NOTE

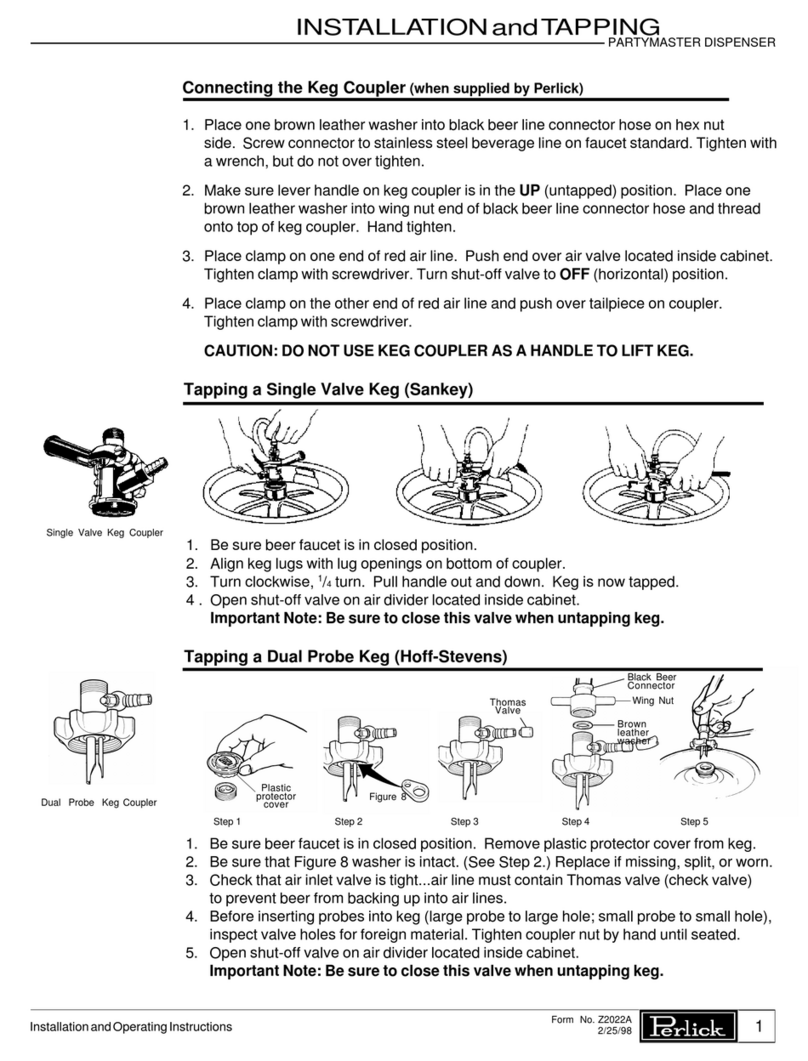

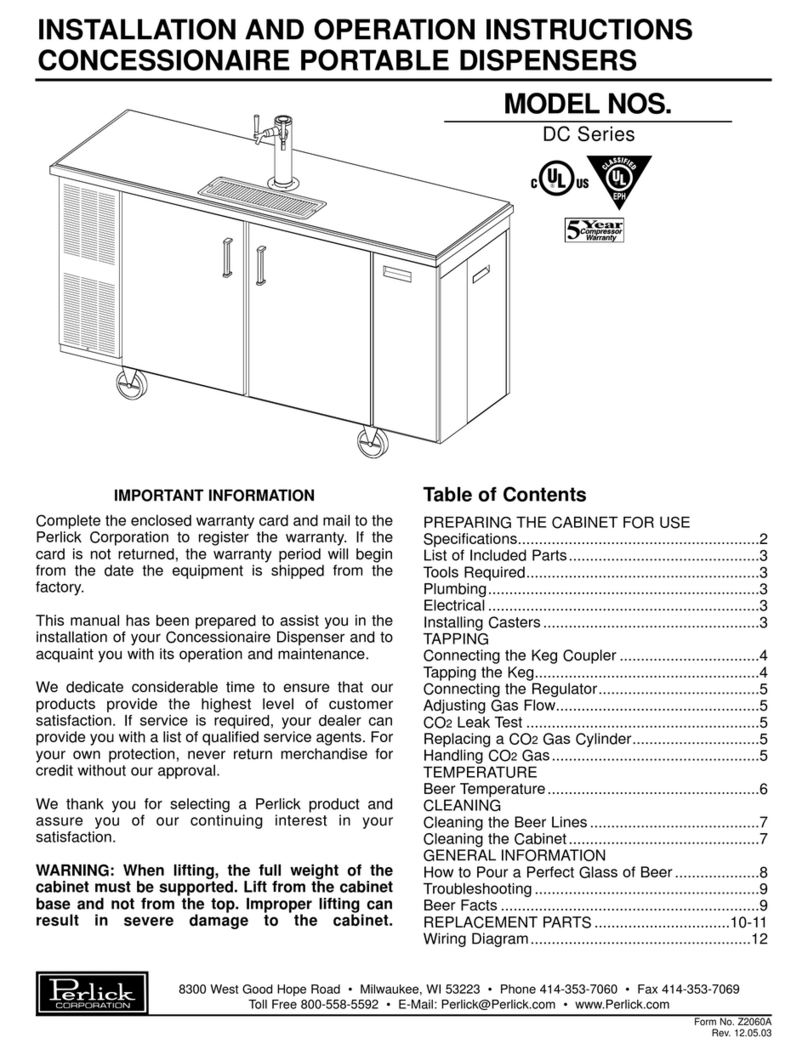

The following instructions are for both the

Draft Arm (standard tower) and the Adara

Signature Beer Tower. Some photos and

drawings may only show the Draft Arm, but

the instructions will also apply to the Adara

Signature Beer Tower unless noted.

INTRODUCTION

DANGER

!

DANGER

!

CAUTION

CAUTION