4

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Operation Instructions – Glass Frosters

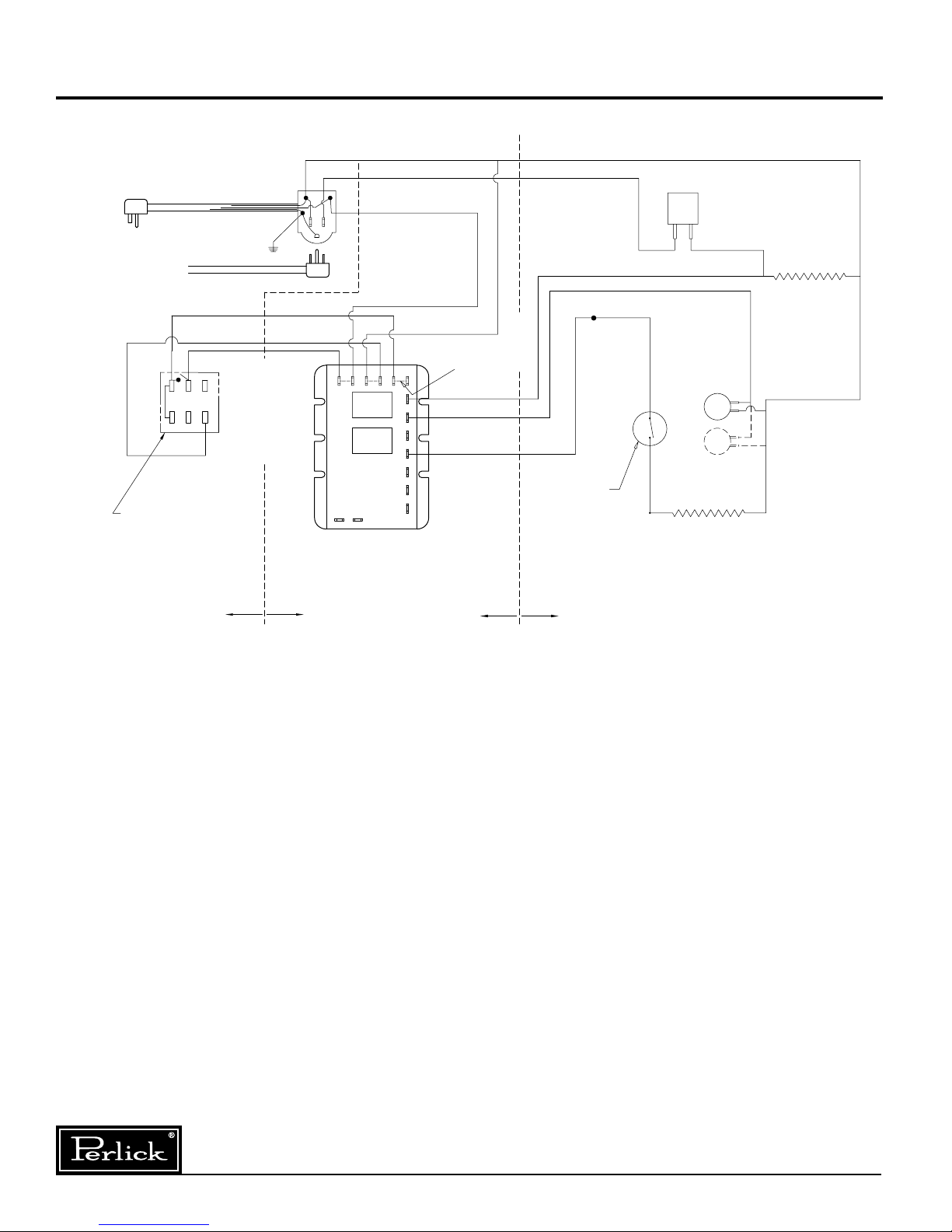

Defrost System

This system consists of a six-hour, as well as a four

hour defrost cycle. The six hour defrost cycle is

manually activated and automatically terminated,

while the four hour cycle is completely automatic.

The Six Hour Solid-State Defrost Timer

This timer shuts off the power to the condensing

unit, door frame heater, evaporator heater, and the

automatic four hour defrost timer, while it supplies

power to the evaporator fan.

To activate the six hour defrost system, depress

the defrost switch located on the front grill of the

cabinet. An amber light will illuminate and the

defrost cycle will begin. When the defrost cycle

ends, the light goes off and the cabinet resumes

normal operation. To manually cancel the defrost

cycle, momentarily turn off the electricity to the

machine.

The Four Hour Defrost Timer

This timer ensures that frost will not buildup on the

evaporator coil. Every four hours it shuts down the

condensing unit and evaporator fan and supplies

power to the defrost element clamped to the bot-

tom of the evaporator. The defrost cycle lasts for

approximately 20.

During normal operation it is recommended that

the doors are not left open to prevent excessive

frost buildup on the coil.

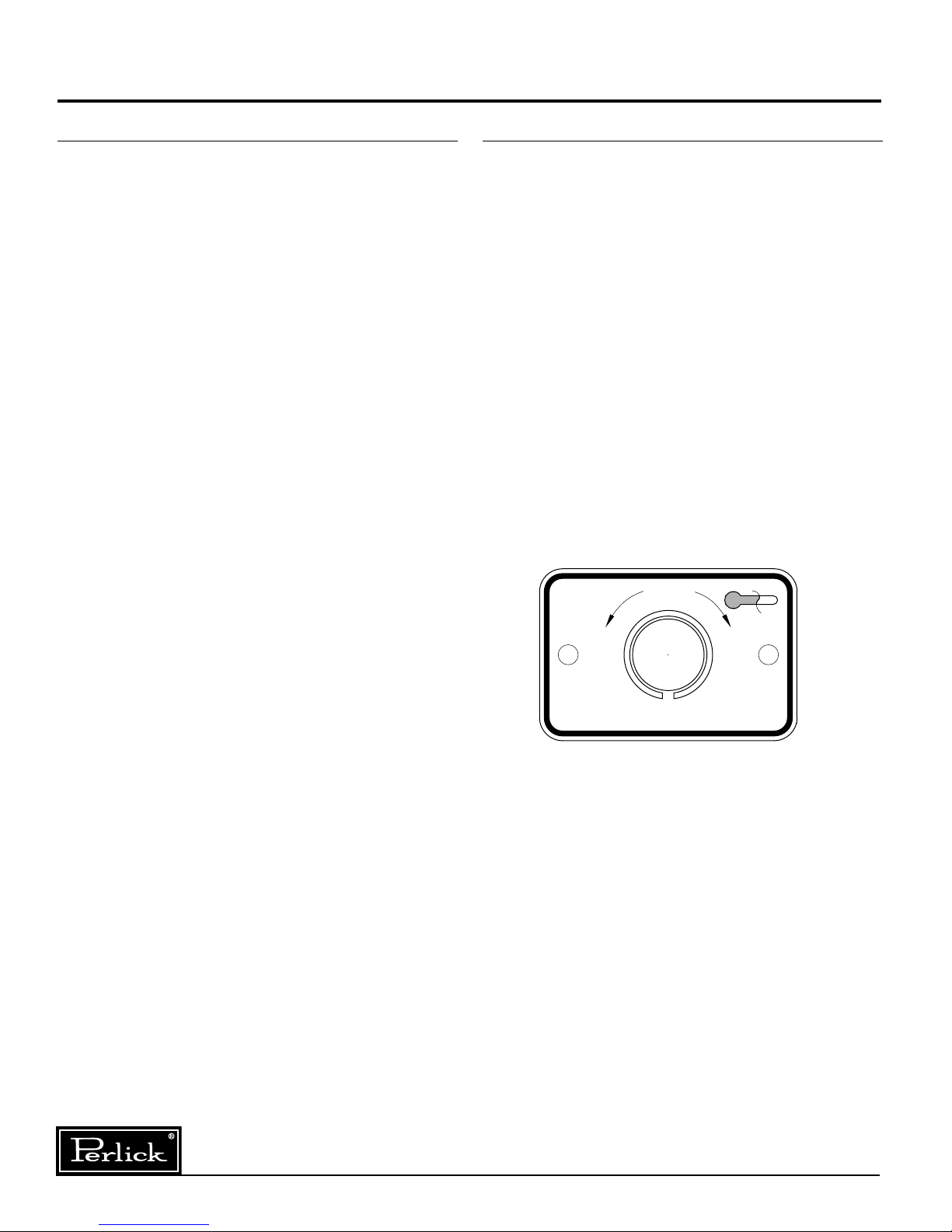

Temperature Control

An adjustable temperature control is located inside

the froster on the evaporator fan panel assembly.

Approximate temperature operating range: minus

15° F. minimum and plus 10° F. maximum. Make

adjustments as shown to attain the desired

temperature.

■Colder Temperatures: Turn the adjusting

screw clockwise (to the right).

■Warmer Temperatures: Turn the adjusting

screw counterclockwise (to the left).

■Temperature Control “OFF”: Turn the

adjusting screw completely counterclock-

wise to the “O” position until a click is

noted.

The condenser fan motor turns off and on with

the compressor. The evaporator fan motor runs

continuously, except during the 20 minute

period of the four-hour defrost.

NORMAL

05

4

6

1

9

2

8

3

7

WARMER

COOLER

CONDENSING UNIT

Form No. Z2296

Rev. 12.05.09