Contents

128 Series Line Stop Plug ......................................................................................................................................................................... ii

Important Safety Instructions.................................................................................................................................................................. 1

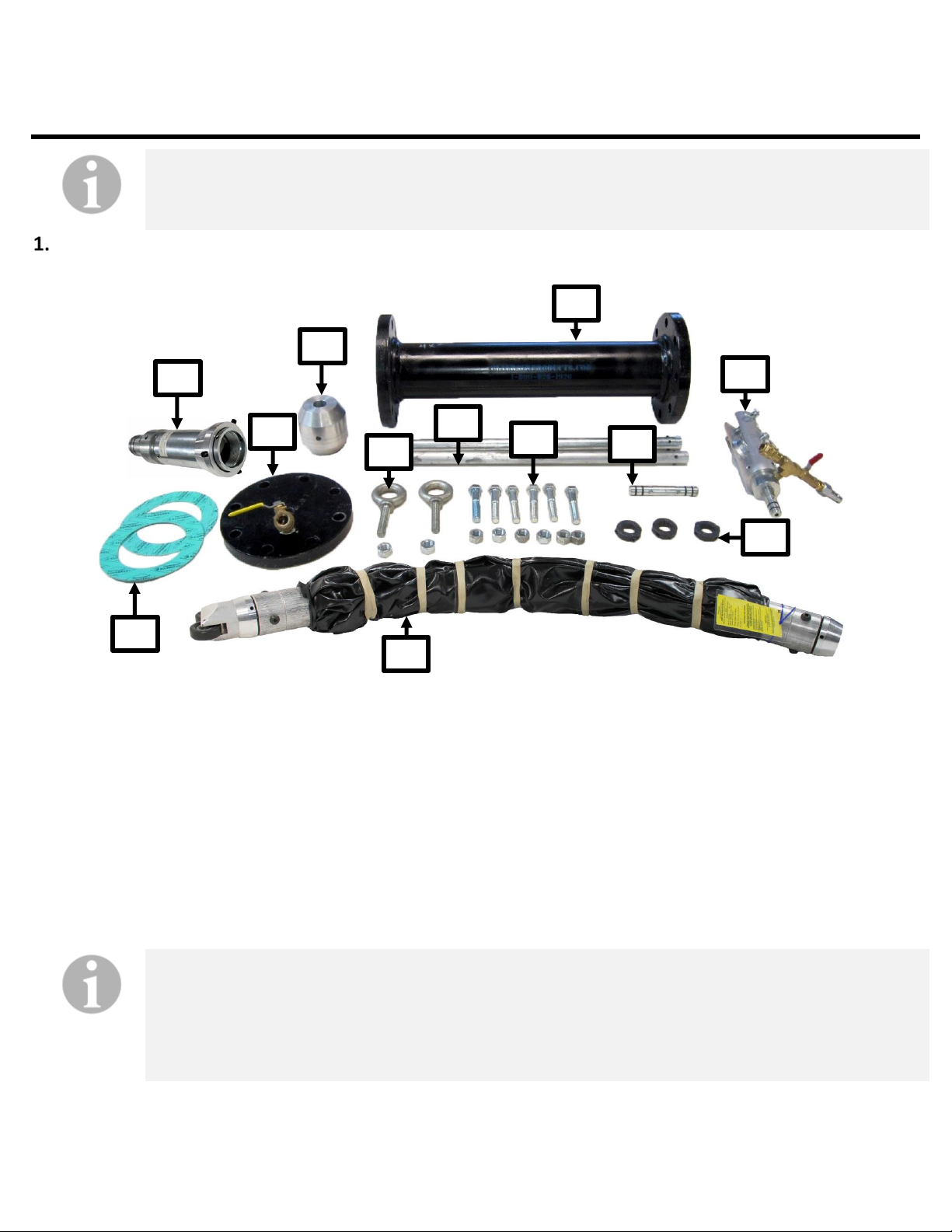

Pre-installation Inspection....................................................................................................................................................................... 2

Assembly Overview .................................................................................................................................................................................4

Hot Tap Insertion Tool Checklist .............................................................................................................................................................. 5

Overview.................................................................................................................................................................................................. 5

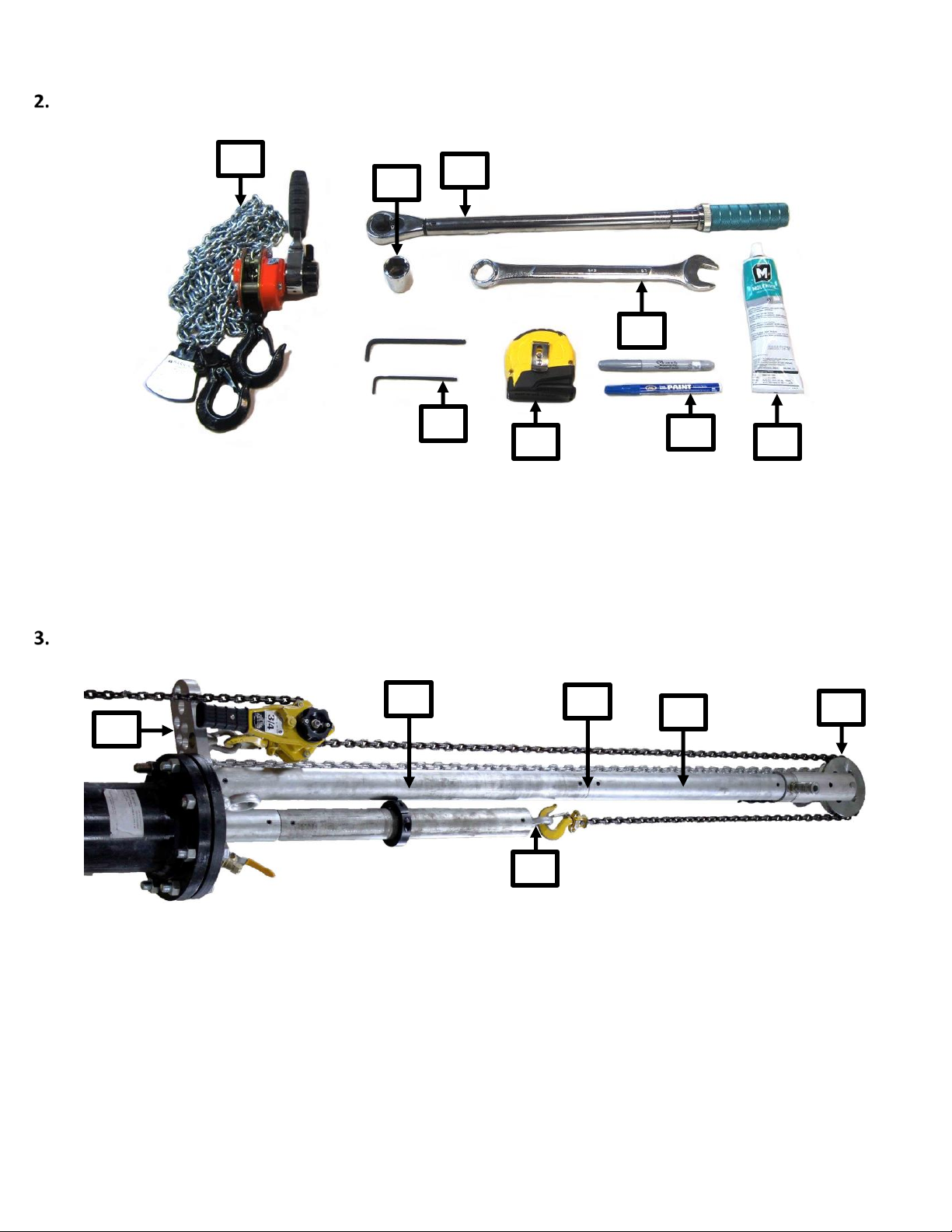

Tool List ...................................................................................................................................................................................................5

Launch Cylinder........................................................................................................................................................................................5

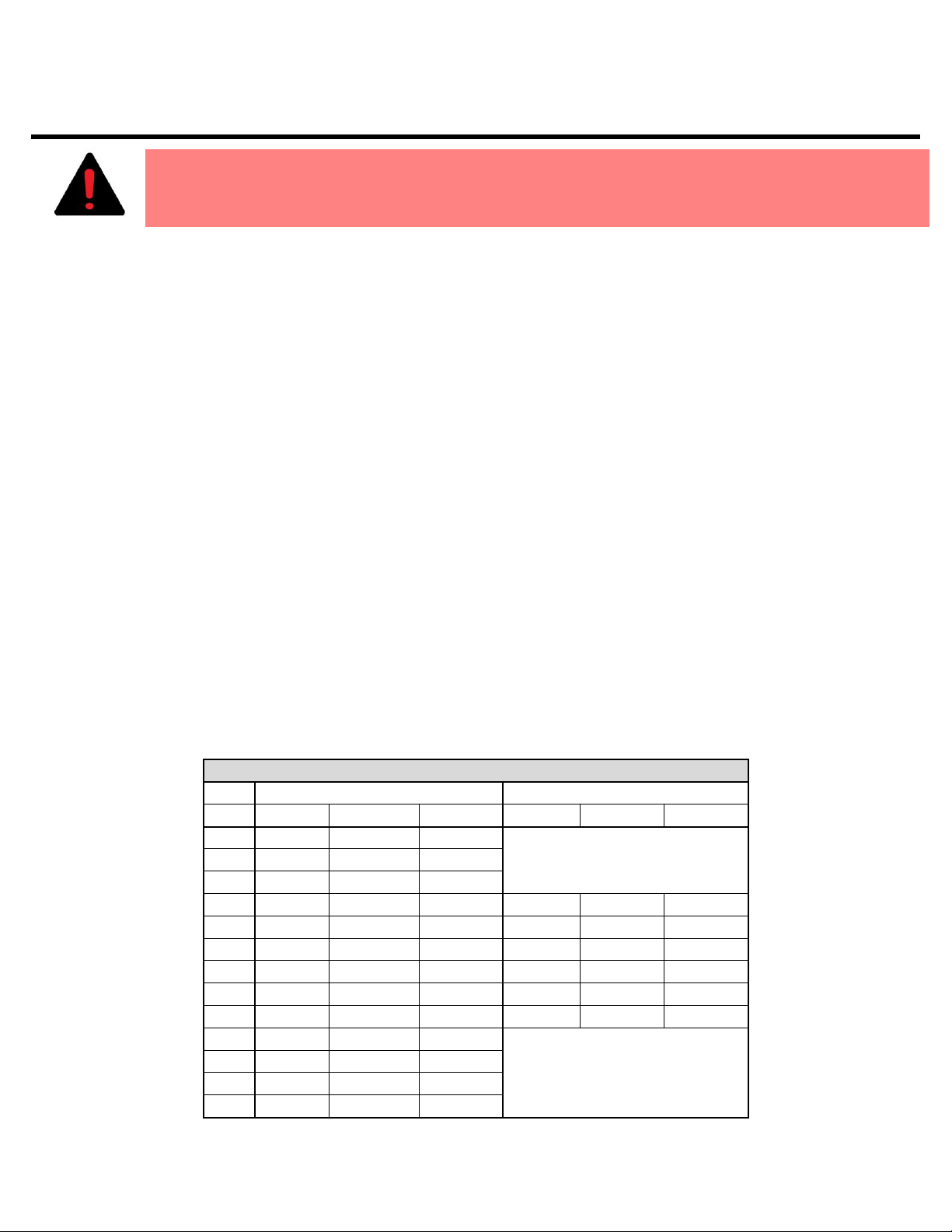

Torque Figures .........................................................................................................................................................................................5

Calculating the Head Pressure ................................................................................................................................................................. 6

Tapping the Pipe......................................................................................................................................................................................6

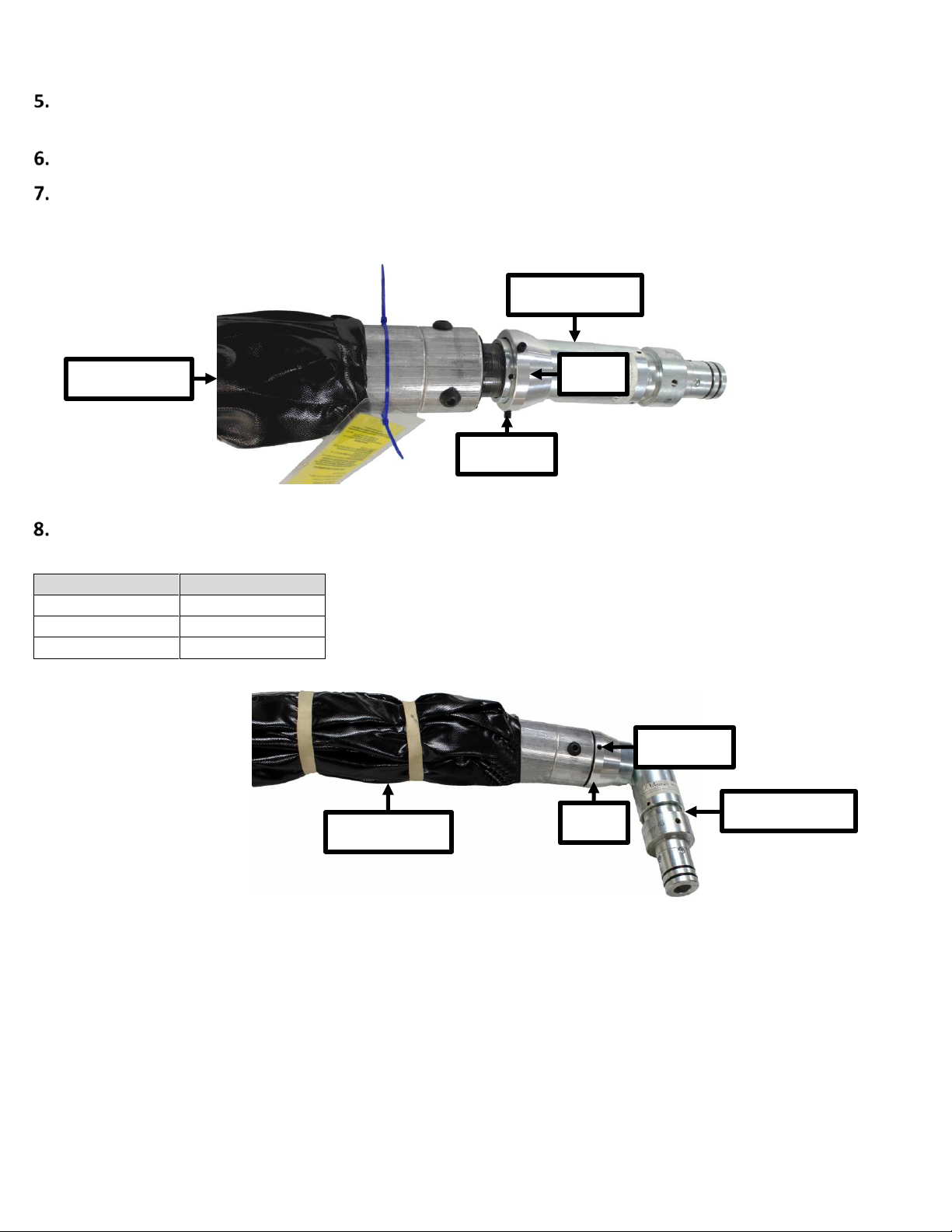

Attaching the Rotating Elbow Assembly .................................................................................................................................................. 7

Assembling the Launch Cylinder .............................................................................................................................................................. 9

Measuring the Assembly........................................................................................................................................................................ 10

Attaching the Main Stop Collar.............................................................................................................................................................. 12

Assembling the Insertion System........................................................................................................................................................... 13

Attaching the Insertion System.............................................................................................................................................................. 15

Inserting the Plug................................................................................................................................................................................... 18

Air Inflation Kit ...................................................................................................................................................................................... 20

Assembling the Air Inflation Kit ............................................................................................................................................................. 21

Deflating Air from the Line Stop Plugs ................................................................................................................................................... 23

Water Inflation Controller ..................................................................................................................................................................... 23

Overview................................................................................................................................................................................................ 23

Operating the Water Flow Totalizer:....................................................................................................................................................... 24

Assembling the Water Hoses and Pressure Monitoring Lines .................................................................................................................. 24

Inflating the Line Stop Plug with Water................................................................................................................................................... 26

Deflating Water from the Line Stop Plugs ............................................................................................................................................... 27

Removing the Line Stop Plug ................................................................................................................................................................. 29

Cleaning and Storing.............................................................................................................................................................................. 31