Contents ..................................................................................Page

1Adjustment ........................................................................................................................... 6

1.01 Tools, gauges and other accessories .................................................................................... 6

1.02 Abbreviations ......................................................................................................................... 6

1.03 Explanation of the symbols.................................................................................................... 6

1.04 Adjusting the basic machine .................................................................................................. 7

1.04.01 Needle position in sewing direction (on the PFAFF 571 and 591) ......................................... 7

1.04.02 Needle position in sewing direction (on the PFAFF 574)........................................................ 8

1.04.03 Preliminary adjustment of the needle height......................................................................... 9

1.04.04 Needle rise, hook clearance, needle height and needle guard (on the PFAFF 571)................. 10

1.04.05 Needle rise, hook clearance, needle height and needle guard (on the PFAFF 574) .................12

1.04.06 Needle rise, hook clearance, needle height and needle guard (on the PFAFF 591).................14

1.04.07 Needle position crosswise to sewing direction (on the PFAFF 571).................................... 16

1.04.08 Needle position crosswise to sewing direction (on the PFAFF 574) .................................... 17

1.04.09 Needle position crosswise to sewing direction (on the PFAFF 591).................................... 18

1.04.10 Height and stroke of the bobbin case opener...................................................................... 19

1.04.11 Height of the feed wheel (on the PFAFF 571)...................................................................... 20

1.04.12 Height of the feed wheel (on the PFAFF 574) ...................................................................... 21

1.04.13 Height of the feed wheel (on the PFAFF 591)...................................................................... 22

1.04.14 Stitch length control eccentric ............................................................................................. 23

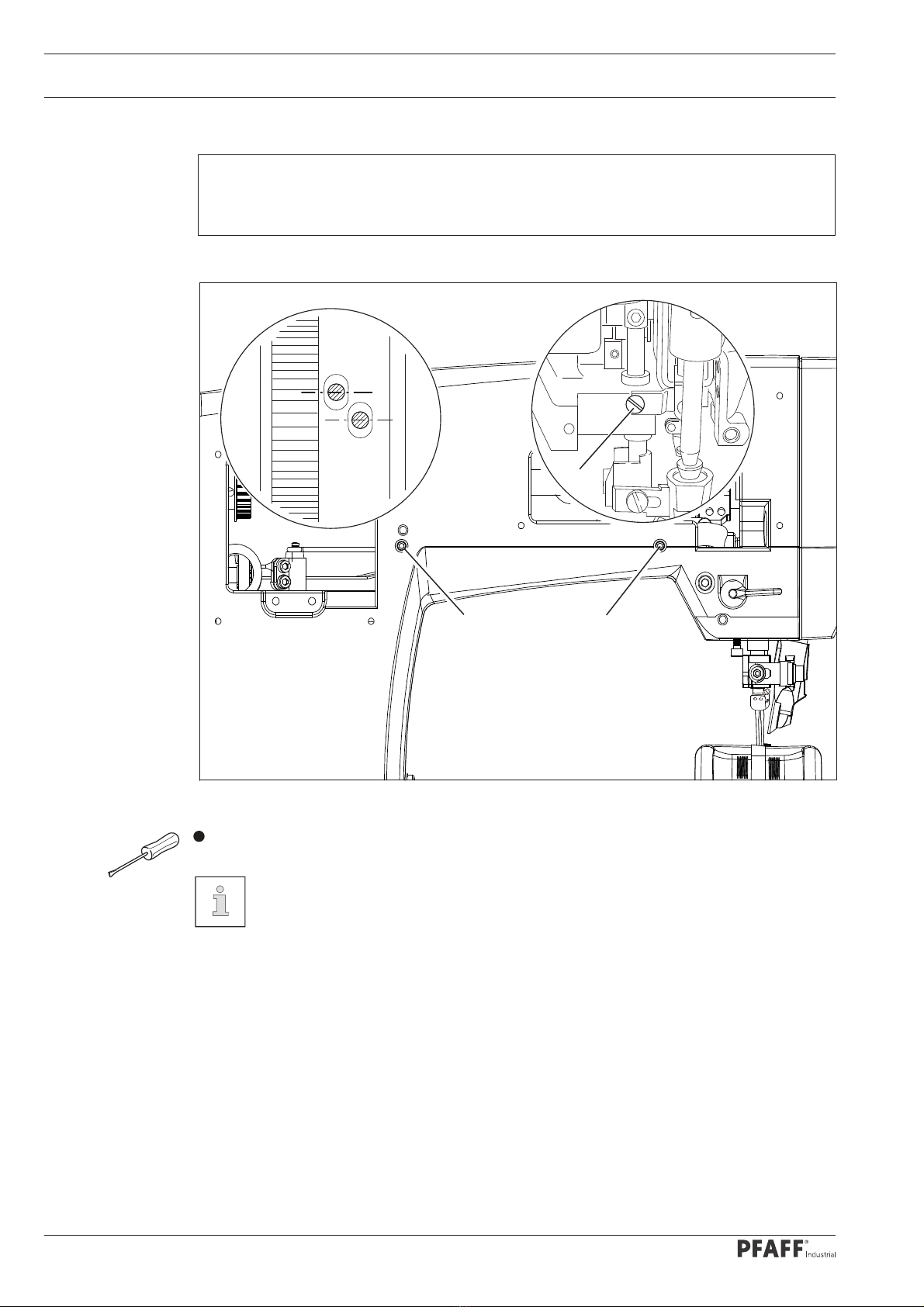

1.04.15 Stitch length scale disk ........................................................................................................ 24

1.04.16 Shaft crank to feed wheel drive ........................................................................................... 25

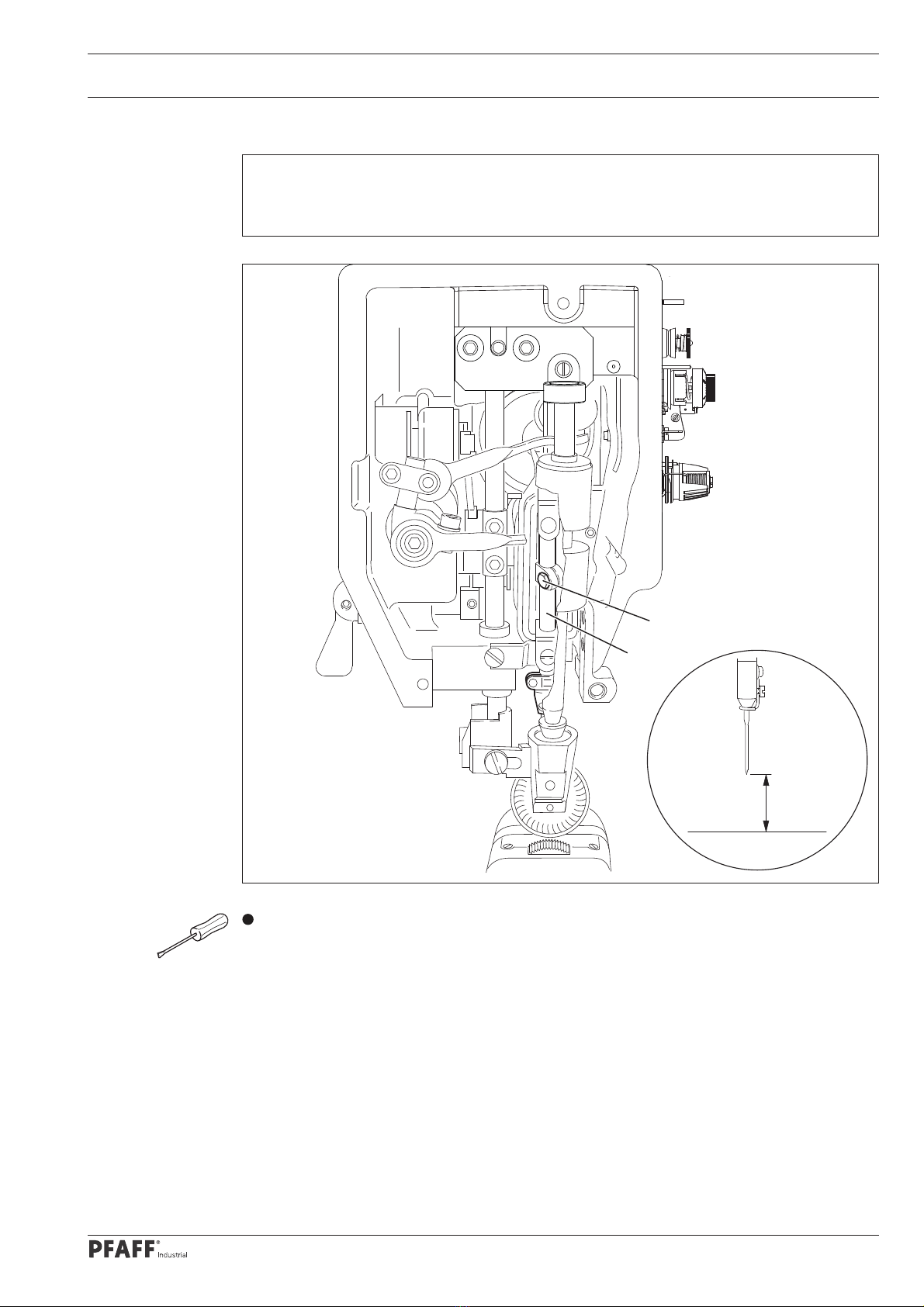

1.04.17 Shaft crank to roller presser drive ........................................................................................ 26

1.04.18 Clearance between roller presser and feed wheel .............................................................. 27

1.04.19 Roller presser....................................................................................................................... 28

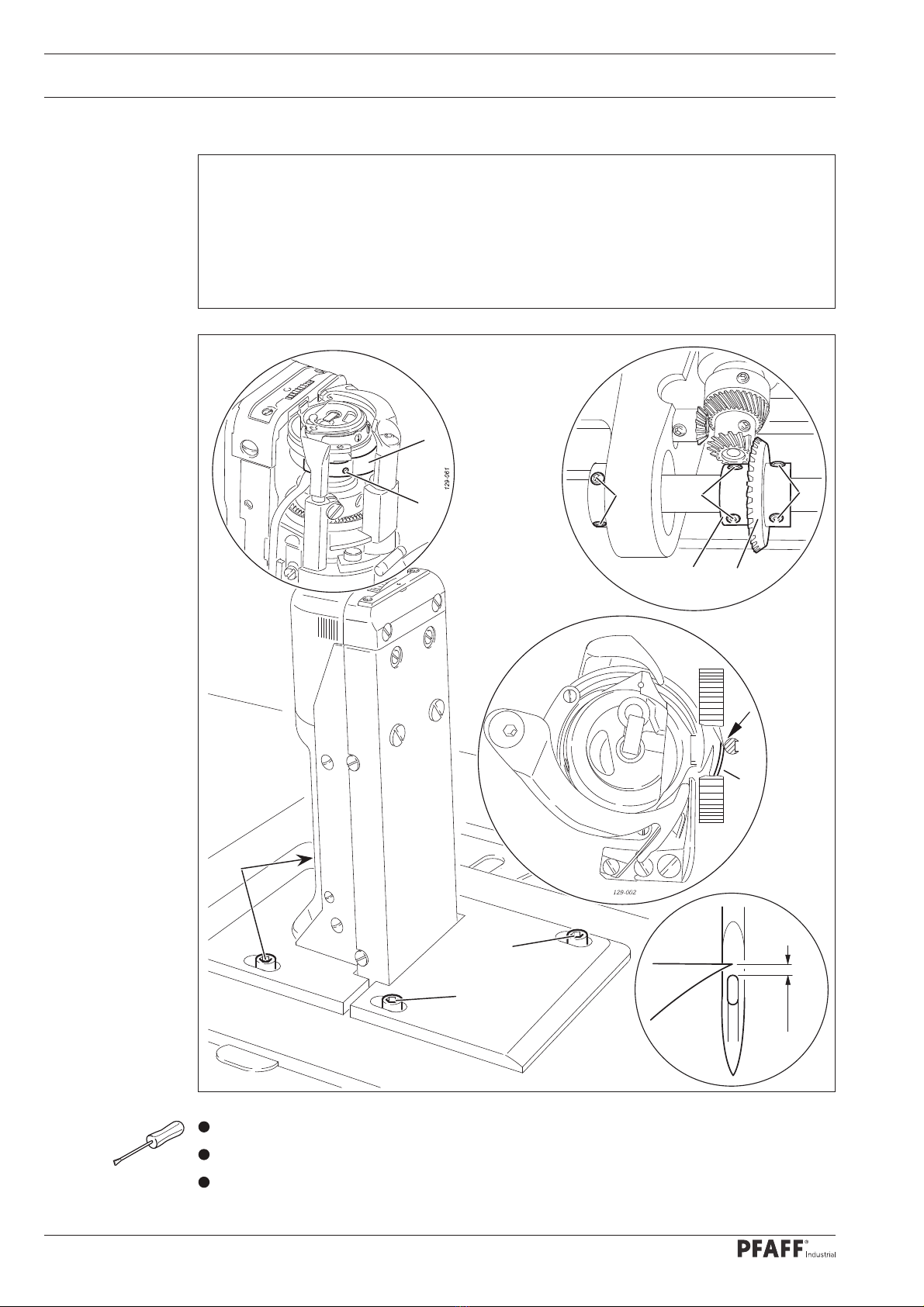

1.04.20 Stitch length on stitch length scale ...................................................................................... 29

1.04.21 Synchronization of roller presser and feed wheel ................................................................ 30

1.04.22 Retainer (only on model 574) ............................................................................................... 31

1.04.23 Knee lever ............................................................................................................................ 32

Index