Index

Contents ................................................................................................. Page

1Proper use ........................................................................................................................... 4

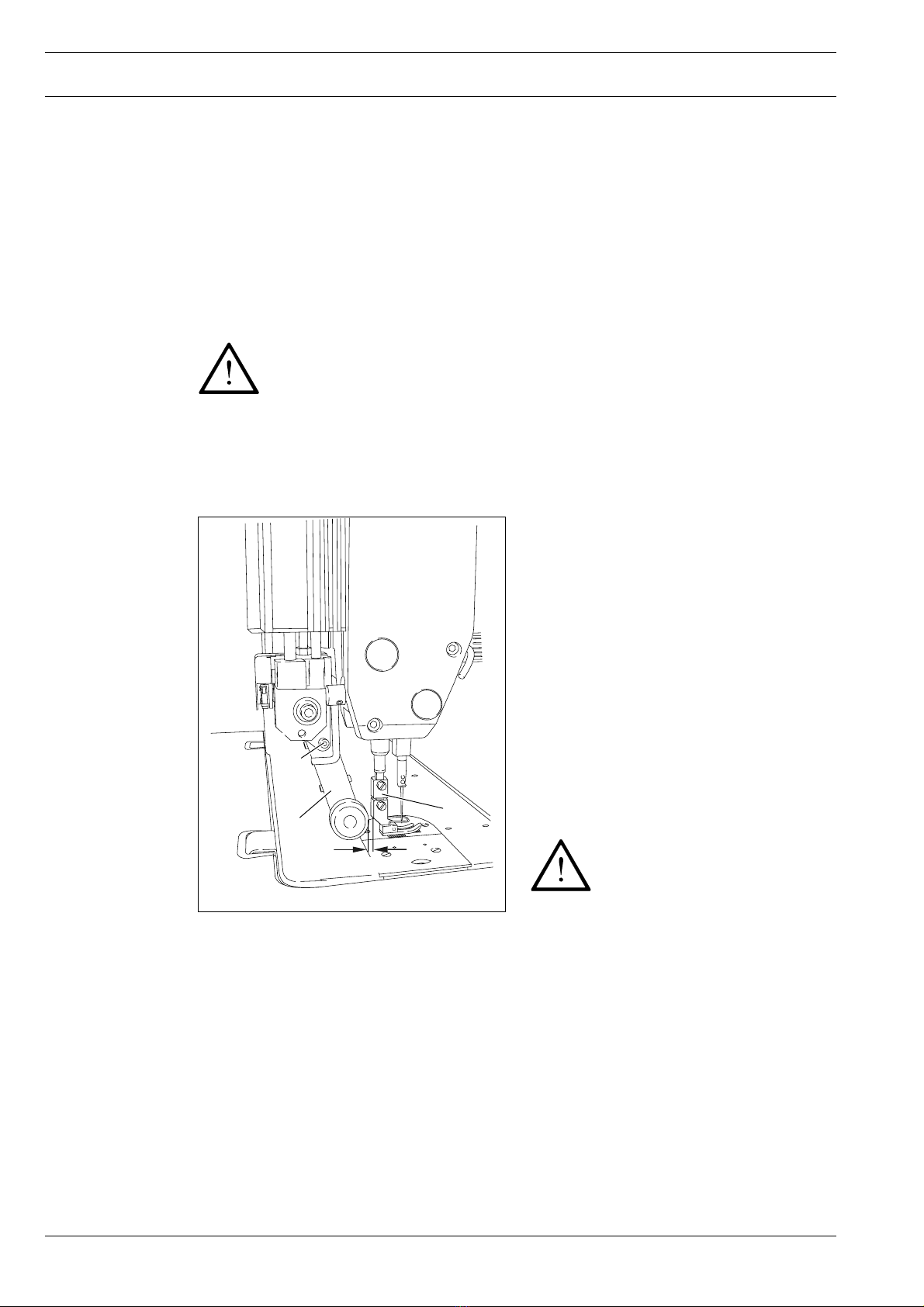

1.01 Using standard presser feet ................................................................................................. 4

2Controls .............................................................................................................................. 5

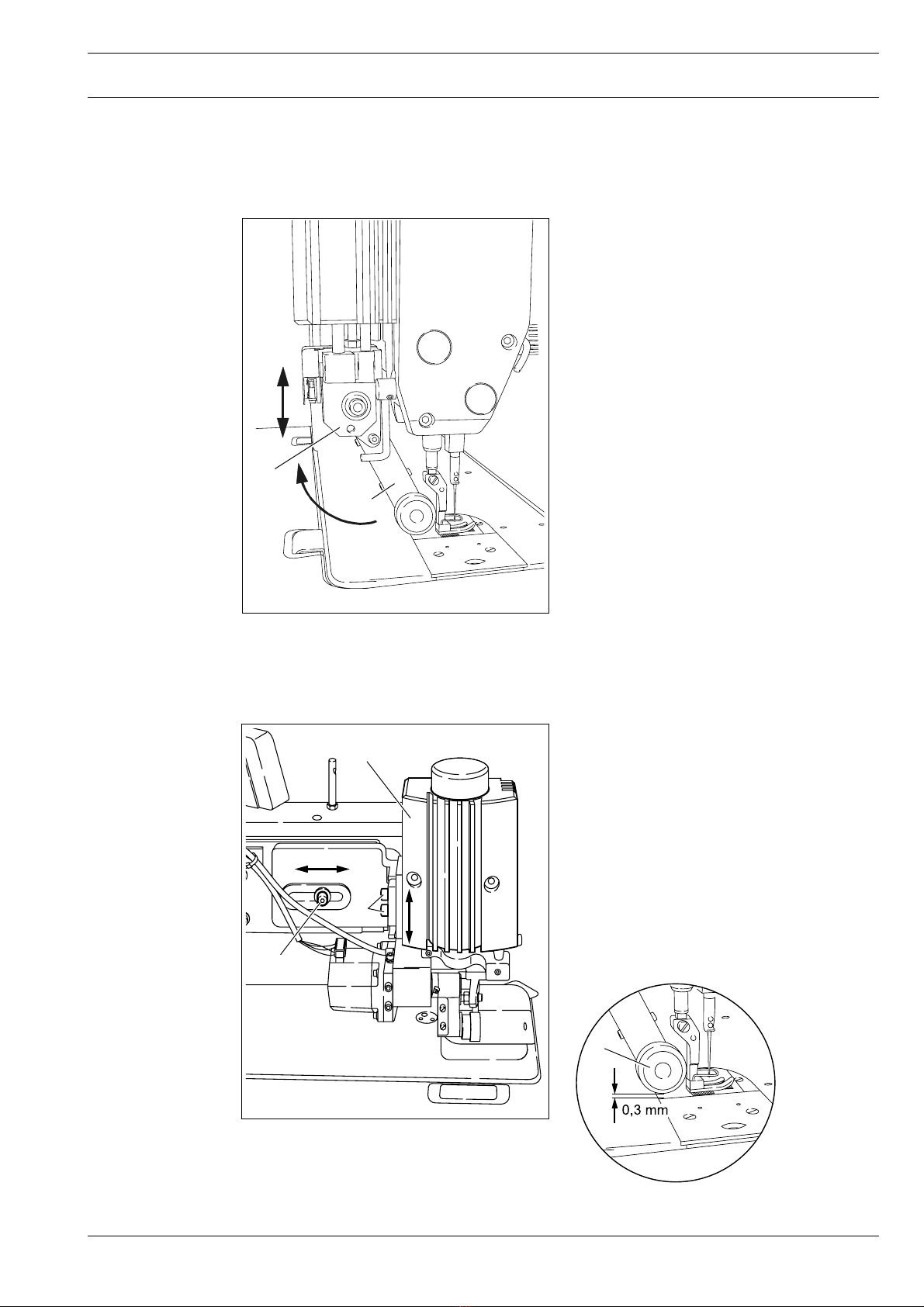

2.01 Puller functions .................................................................................................................... 5

2.02 Aligning the puller ................................................................................................................ 5

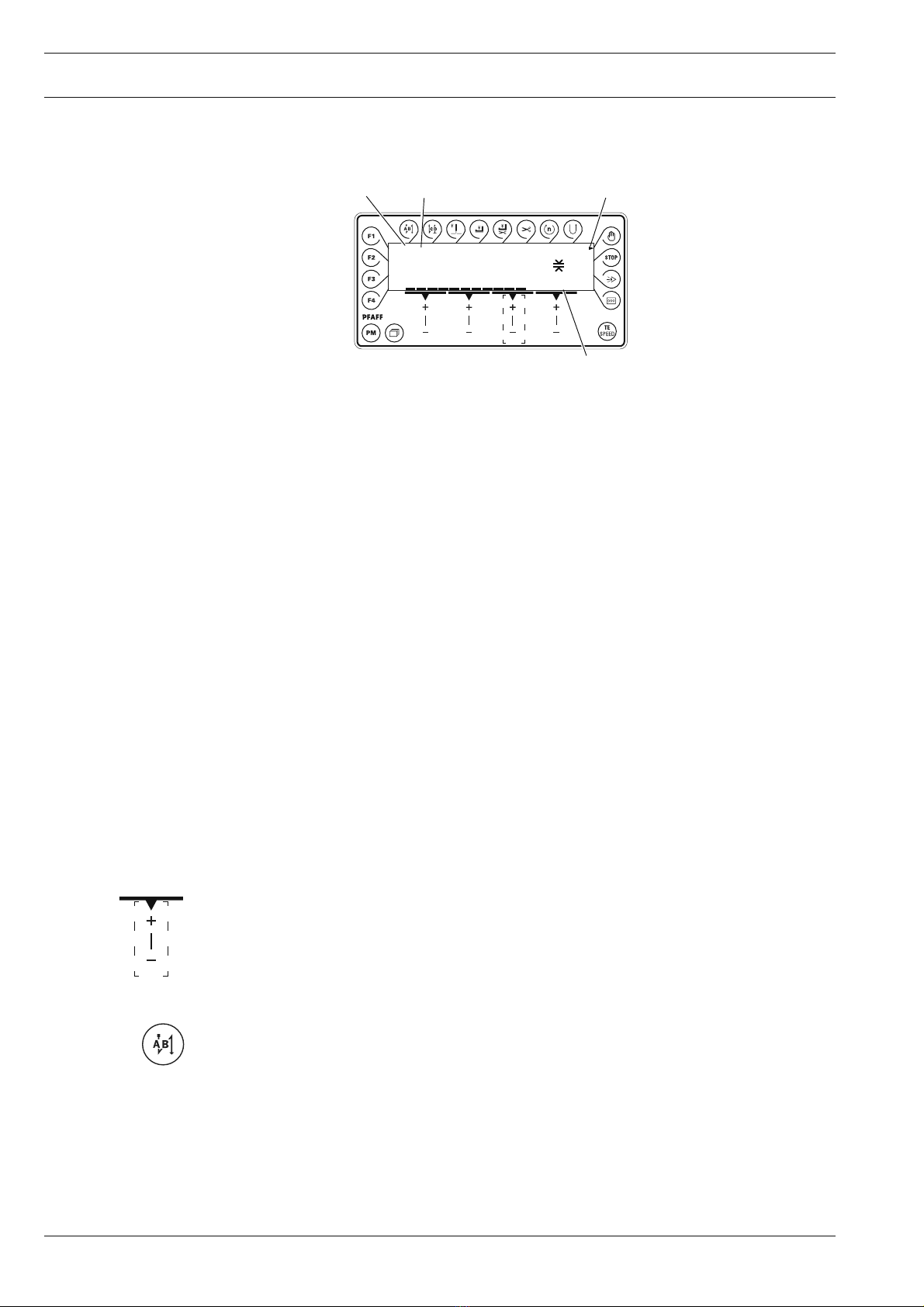

2.03 Control panel ........................................................................................................................ 6

2.03.01 Screen displays .................................................................................................................... 6

2.03.02 Function keys ....................................................................................................................... 6

2.03.03 Selecting and altering parameters ........................................................................................ 9

2.03.04 Selecting the user level ...................................................................................................... 10

3Commissioning ................................................................................................................ 11

3.01 Basic position of the machine drive ................................................................................... 11

3.02 Testing the function of the start inhibitor ........................................................................... 12

4Setting up ......................................................................................................................... 13

4.01 Entering the puller feed stroke (stitch length) .................................................................... 13

4.02 Setting the puller pressure ................................................................................................. 13

4.03 Entering the maximum speed ............................................................................................ 14

4.04 Entering the start and end backtacks ................................................................................. 14

4.05 Setting the stitch counting function for the bobbin thread control ..................................... 15

5Sewing ................................................................................................................................ 1

5.01 Manual sewing ..................................................................................................................... 1

5.02 Programmed sewing ............................................................................................................2

5.03 Error messages .................................................................................................................... 3

6Parameter Settings ........................................................................................................... 16

7Software-Update .............................................................................................................. 21

8Reset / Kaltstart ................................................................................................................ 22

9Partslist ............................................................................................................................. 23

10 Circuit diagrams ............................................................................................................... 24