Column maintenance

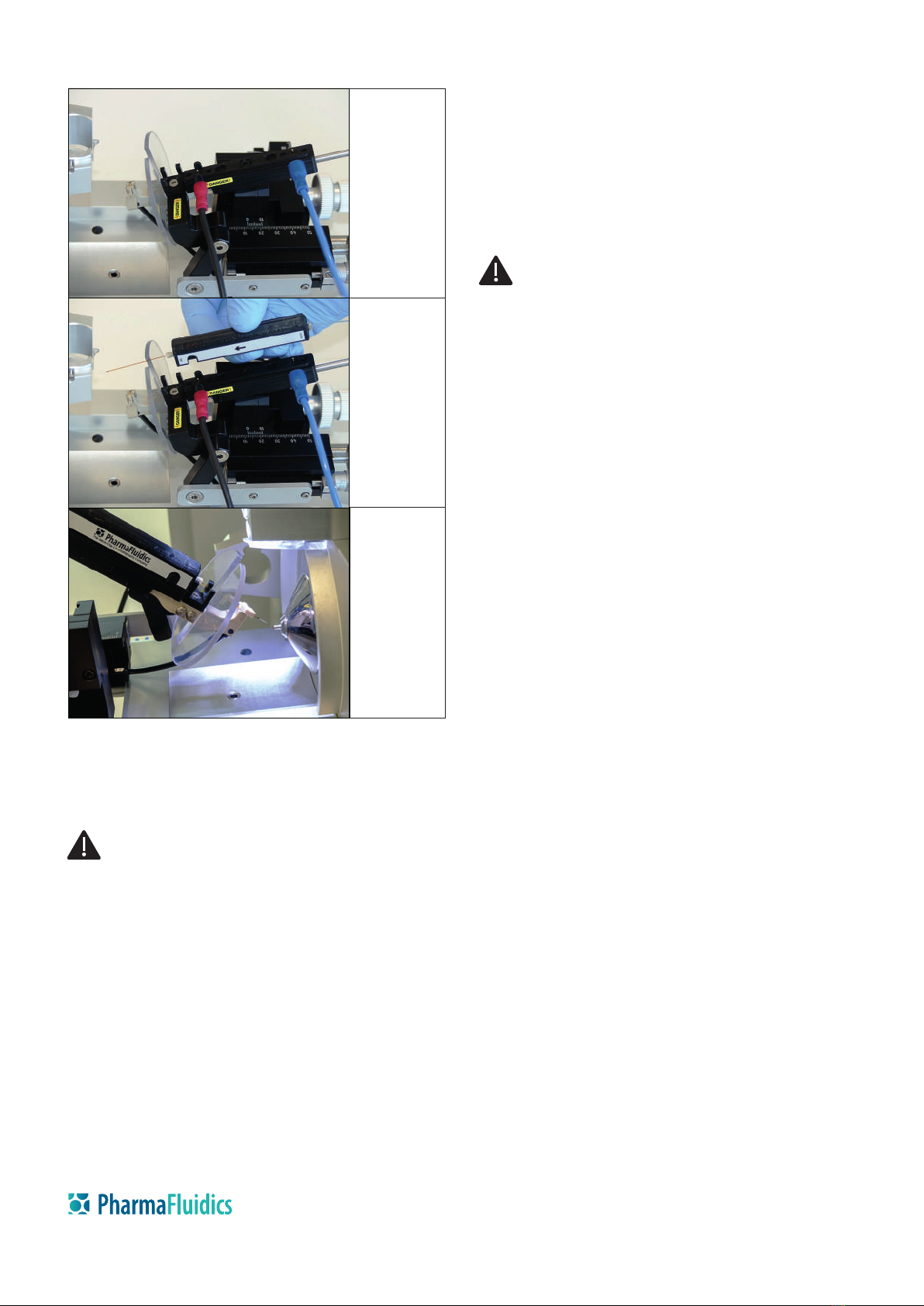

Figure 2. Installation of the µPAC™ Flex iON Connect on a ThermoFisher

Scientic Nanospray Flex™ ion source. Upper panel: mounting the docking

unit; middle panel: mounting the spray unit; lower panel: adjusting the

position of the emitter.

The µPAC™ Flex iON Connect MS interface is designed to be used in the nanoLC ow

range of 50 to 1,000 nL/min, with a maximum ow rate of approximately 1,500

nL/min. Selecting the appropriately-dimensioned emitter tip opening is crucial in

obtaining optimal spray quality for your specic application. In general, analyses at

a higher nanoLC ow rate (500-1500 nL/min) will benet from emitters with larger

tip openings (20-30 µm). Emitter tip openings ≤ 10 µm will give the best results for

analyses in the lower nanoLC ow range (50-500 nL/min). Although smaller tip

openings generate an optimal spray for reduced sample volumes, the risk of

blockage increases and, subsequently, more frequent exchange of the emitter is

inevitable.

www.pharmafluidics.com

Technologiepark-Zwijnaarde 82

B-9052 Ghent (Zwijnaarde)

Belgium

For research use only

Mounting the docking unit Mounting the spray unit Adjusting emitter tip posotion

CAUTION Avoid contact with high voltage. Before installing the µPAC™

Flex iON Connect interface, ensure that the mass spectrometer is in

stand-by and fully retract the DirectJunction™ adaptor to the end of

the sliding rails on the source. Then disconnect the HV cable from the

bottom of the NanoSpray Flex™ source.

Mobile phase

•

•

µPAC™ Flex iON Connect routine operation

•

•

•

Disconnecting the µPAC™ Flex iON Connect

•

•

Part numbers for spares and consumables

PharmaFluidics grounding cable ACC-groundcable

PharmaFluidics µPAC™ Flex iON Connect EMI-exion

VICI one-piece PEEK tting for 360 µm O.D. tubing C360NFPKG

VICI one-piece PEEK tting plug C360PPK

VICI ZDV union end plug ZU.5FPK

ESI emitter consumables

Fossil Ion Tech 360 O.D. x20 µm I.D. x5 cm FIT-20-5

Fossil Ion Tech 360 O.D. x10 µm I.D. x5 cm FIT-10-5

New Objective PicoTip emitter 10 µm tip, 5cm FS360-20-10-N-20

New Objective PicoTip emitter 15 µm tip, 5cm FS360-50-15-N-20

Further information

For column specications, pressure limits, pH range, tips and tricks including

operational instructions, visit:

https://www.pharmafluidics.com/products/

For technical support visit:

https://www.pharmafluidics.com/contact/

Turn o the spray voltage on the mass spectrometer.

Stop the HPLC ow and wait until the backpressure of the µPAC™ column has

decreased and stabilised.

Once the upper pressure limit of the HPLC has been adjusted to a maximum

of 350 bar, start the ow through the µPAC™ column and µPAC™ iON Flex

Connect.

Once the back pressure stabilises, apply the ow rate used to analyse

samples, e.g., 300 nL/min.

When the pressure has again stabilised, apply 1.5 kV to the emitter and wait

until the spray stabilises. If the spray does not stabilise, gradually increase

the voltage.

Only use ltered and degassed LCMS-grade mobile phases.

To prevent crystallisation and/or precipitation of solutes, alternate between

miscible mobile phases, e.g., acetonitrile (ACN), methanol (MeOH),

isopropanol (IPA), triuoroacetic acid (TFA), formic acid (FA).

CAUTION Avoid personal injury. Before removing an emitter, ensure

that the LCMS system is fully depressurised and disconnect the HV

cable from the bottom of the source. Else, the emitter may eject at

high speed and cause personal injury to you or someone in the near

vicinity.