iii | P a g e

CAUTION: Long leads between the unit and the motor with an unfiltered PWM voltage can lead

to dangerous voltage rise from reflected harmonics. Very long leads, such as in deep well

submersible pump applications, may require the use of a sine wave filter to remove most of the

harmonics from the waveform. Consult the factory or a knowledgeable source on motor

protection filters if your motor is more than 50 feet from the drive.

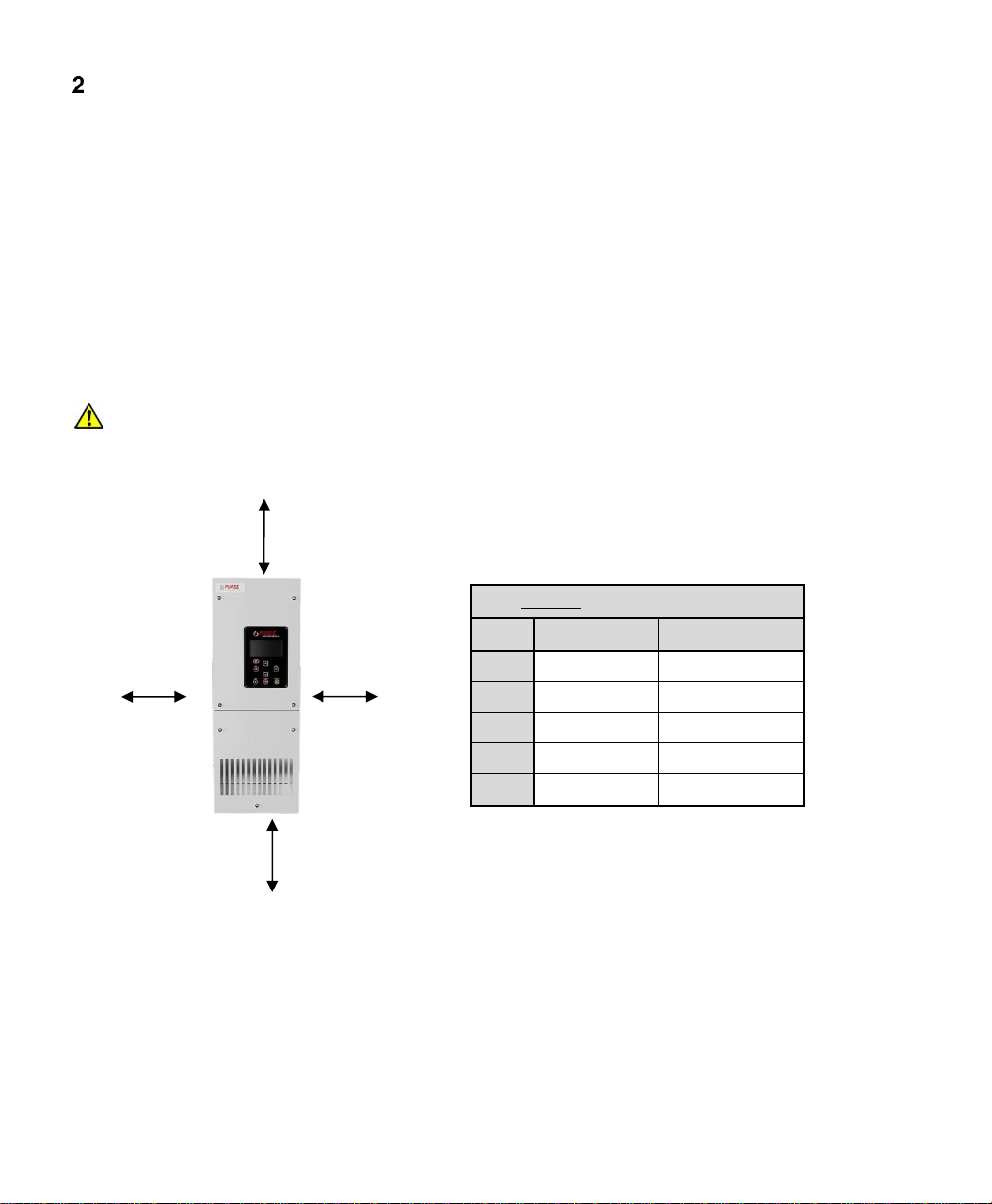

CAUTION: Failure to maintain adequate clearance for free flow of cooling air may lead to

overheating of the unit and cause damage or fire.

WARNING: Suitable for use in a circuit capable of delivering not more than 65 kA RMS

symmetrical amperes, 460 VAC.

WARNING: Wire used within the motor circuit and all field wiring terminals must be rated at least

60 °C.

WARNING: Use wire size suitable for Class 1 circuits.

WARNING: Input power connections should be made by a qualified electrician into a nominal

460V circuit for models with 460V input, with adequate current carrying capacity. Branch circuit

protection to the drive should be provided by appropriate size fuses or circuit breaker. Circuit

breaker and fuse ratings for each model are listed in Table 2, Table 3, and Table 4.

WARNING: These devices are equipped with integral solid-state short circuit protection. Integral

solid-state short circuit protection does not provide branch circuit protection. Branch circuit

protection must be provided in accordance with the National Electrical Code and any additional

local codes.

CAUTION: Use 600 V vinyl-sheathed wire or equivalent. The voltage drop of the leads needs to

be considered in determining wire size. Voltage drop is dependent on wire length and gauge.

Use copper conductors only.

CAUTION: Wires fastened to the terminal blocks shall be secured by tightening the terminal

screws to a torque value listed in Table 2, Table 3, and Table 4.

CAUTION: The maximum wire gauge for the input and output terminals are listed in Table 2,

Table 3, and Table 4.

CAUTION: Never allow bare wire to contact the metal surfaces.

CAUTION: Never connect AC main power to the output terminals U, V, and W.