1About this Document 1

1.1 Objective and Target Audience of this User Manual.................................................. 1

1.2 Symbols and Typographic Conventions...................................................................... 1

1.3 Definition.................................................................................................................... 2

1.4 Figures ........................................................................................................................ 2

1.5 Other Applicable Documents ..................................................................................... 3

1.6 Downloading Manuals................................................................................................ 3

2Safety 5

2.1 Intended Use .............................................................................................................. 5

2.2 General Safety Instructions ........................................................................................ 5

2.3 Organizational Measures............................................................................................ 6

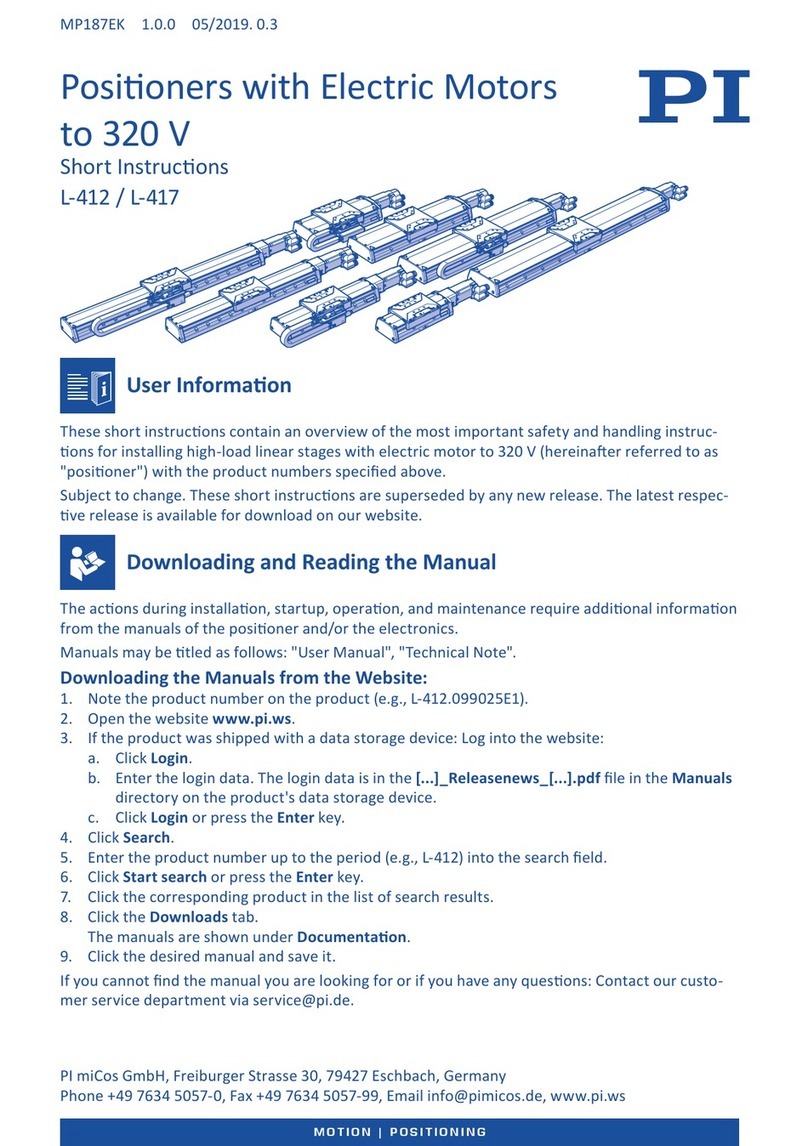

3Product Description 7

3.1 Model Overview ......................................................................................................... 7

3.2 Product View .............................................................................................................. 9

3.3 Direction of Motion.................................................................................................... 9

3.4 Product Labeling....................................................................................................... 10

3.5 Scope of Delivery...................................................................................................... 11

3.6 Accessories ............................................................................................................... 12

3.7 Suitable Controllers .................................................................................................. 12

3.8 Technical Features.................................................................................................... 13

3.8.1 Encoder........................................................................................................ 13

3.8.2 Limit Switches.............................................................................................. 13

3.8.3 Reference Point Switch................................................................................ 13

3.8.4 Integrated PWM Amplifier .......................................................................... 13

4Unpacking 15

5Installation 17

5.1 General Notes on Installation................................................................................... 17

5.2 Mounting the L-509 onto a Surface ......................................................................... 19

5.3 Connecting the L-509 to the Protective Earth Conductor........................................ 22

5.4 Affixing the Load to the L-509 .................................................................................. 24

5.5 Setting Up a Multi-Axis System ................................................................................ 25

5.5.1 General Information on Setting Up a Multi-Axis System ............................ 25

5.5.2 Setting Up an XY System.............................................................................. 26

5.5.3 Setting Up a Z System.................................................................................. 28

5.6 Connecting the L-509 to the Controller.................................................................... 31

5.7 Connecting the Power Supply to the L-509.............................................................. 32

Contents