User Manual TOPACC-HC

1. INTRODUCTION

The bipolar Zero-fluxcurrent transformer System TOPACC-HC, developed by PM SMS for scientific

research, epitomise the concept of a

galvanic ally separated system for

measurement of direct and

alternating high currents up to 30 kA

with exceptionally high accuracy and

stability.

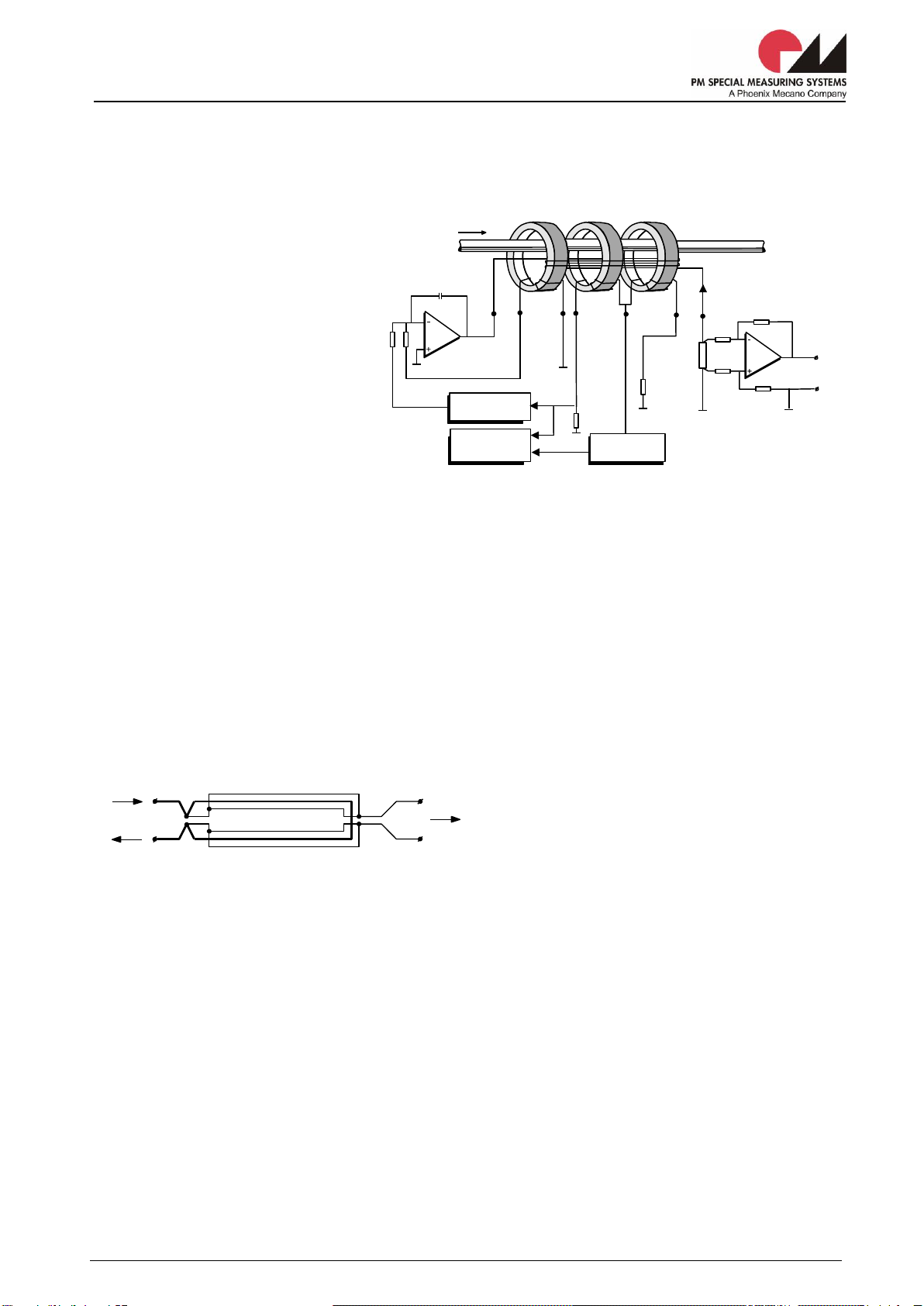

1.1 The basic principle

The principle of measurement is

based on obtaining a perfect balance

between the magnetic flux generated

by the current in the primary current

carrier and that generated by the

current in the secondary winding

situated in the measuring head. This

balance is known as the condition of

zero flux.

The current to be measured is sensed by a toroidal ring core which is mounted around the primary

conductor. A magnetic field is generated by the primary current Ip. The electronics module of the

TOPACC-HC produces a current in the secondary winding of the core in the measuring head, which

creates a counteracting magnetic field. When the magnetic fields balance each other this is known as the

condition of zero-flux. The TOPACC-HC has a magnetic modulator with a patented peak detector. It

continuously checks whether the secondary ampere-turns are in perfect balance with the primary. The

secondary current, which is an exact image of the primary current, is fed trough an external burden

resistor to make the signal available for further use. The TOPACC-HC’s unique design provides high

accuracy and stability without the need for special temperature control devices.

1.2 The burden resistor

Extremely high requirements hold for the burden resistor into which the secondary current is fed. After

amplification in the output circuit of the TOPACC-HC Zero-fluxcurrent transformer the voltage across

this resistor must be suitable to allow very

accurate readings to be made, whether they are

ultimately produced in analogue or digital form. In

view of the required measurement precision a

four-wire resistor is the best. Despite the fact that

high-quality resistors can be purchased on the

industrial market, for technical reasons, PM SMS

much prefers to make its own for the TOPACC-HC.

A special coating contributes to the long-term stability. To achieve a high bandwidth the current and

voltage conductors are put close together in a special way. These measures enable a bandwidth of 1 MHz

to be achieved. To reduce any thermocouple effects which might arise between the alloy of the resis-

tance wire and the copper of the voltage conductors good thermal coupling is made between the two

voltage pick-offs. The thermal stability of the burden resistor under nominal load conditions is, even over

the long term, ensured without the need of resorting to heating elements, Peltier elements or constant

temperature chambers.

1.3 The precision amplifier

The precision amplifier is a very stable differential amplifier, which delivers a highly accurate output

voltage of 10V when the secondary current through the burden resistor meets the rated value. To ensure

that the amplification factor remains constant, the most important point is that the temperature

coefficients of the four amplifier resistors are matched (TCR tracking). The offset error is minimised by

careful choice of the operational amplifier. The precision amplifier is fitted with sensing outputs to

compensate for voltage losses in the externally connected conductors upgrading the measurement

precision of the TOPACC-HC Zero-fluxcurrent transformer. Furthermore, sensitivity to HF interference is

much reduced by capacitive coupling of these outputs.

Fig.1 Basic diagram of the Zero-fluxcurrent transformer

Fig.2 Construction of burden resistor