4-MS1002

MS 1002

1. Important notes

Before starting use your MS1002 please read

this instruction manual exactly. That will help you

to operate the device safe and without any

errors.

The MS1002 matches the relevant safety norms.

Only experts in electric are allowed to repair

electric-devices. By improper repair or use the

device not according to its original purpose

there can occure serious harms for your safety

and the safety of the persons around you. If the

cable for the power supply (230 V) is damaged

let it restore immediatly! If you notice any dama-

ge at the casing or at the plug of the MS1002,

send the device for an inspection to the manu-

facturer, to avoid damage to come.

The MS1002 is only to be used with a washing

machine for home use. Do not use the MS1002

for anything else! Never put the MS1002 in

water or similar liquids. You can clean the device

with a moist cloth. Please pull the plug (230 V)

before each cleaning. When a power failure hap-

pens the MS1002 will switch to its "emergency-

program" to guaranty that the washing machine

can finish its program. By pressing the "Stop"

button the device switches back into the normal

program.

If there is no hot water tap but a sink

with a hot water connection near to

the washing machine you can use

the hot water connection by a "Eck-

fix" piece. You can purchuase the "Eckfix"

piece by us.

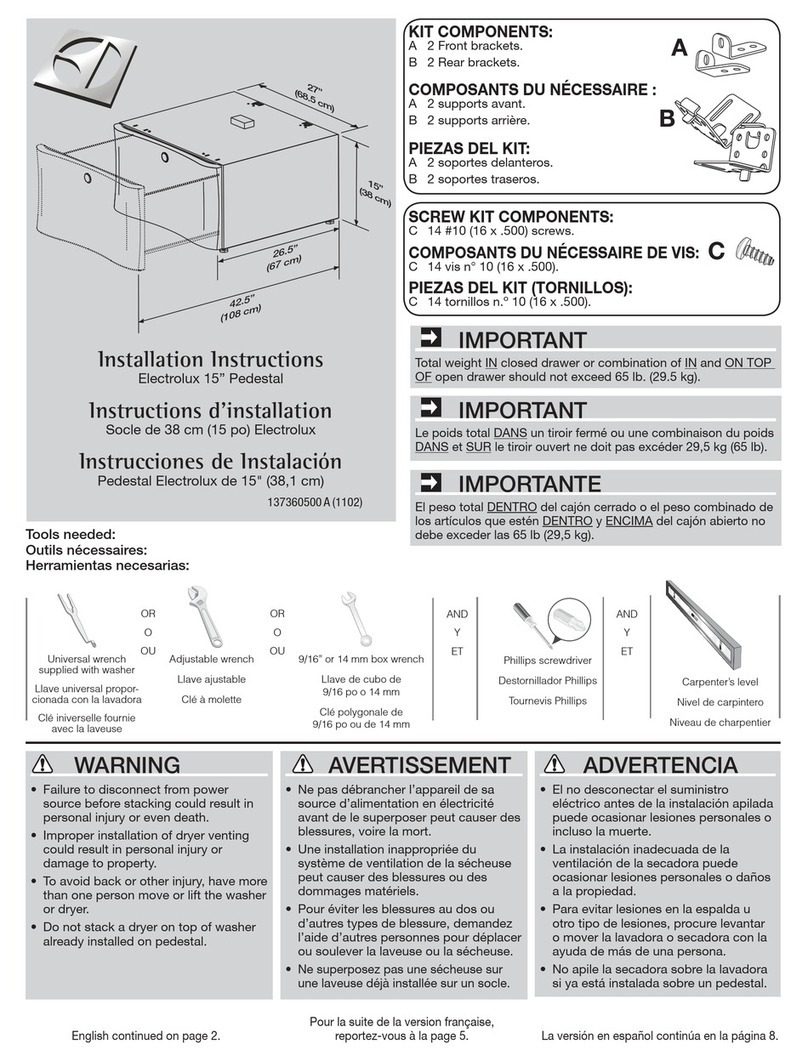

2. Assembly and connection

1. Pull the plug of your washing machine.

2. Unscrew the water hose of the washing

machine at the water tap and even at the was-

hing machine.

3. Remove the sieve, even if you use "Aqua-

Stop", or it could happen that the valve at the

return flow inhibitor can not open properly and

the inflow of cold water is handicapped.

4. Now you can screw the mixing chamber

together with the square hose and the Y-Piece

to your washing machine.

When using "Aqua Stop" remove the

square hose and put your Ypiece

together with the "Aqua Stop" piece

by using a hoseconnector (2 x ¾"

external screw thread). If you are using a

washing machine with "Aqua-Stop" you need

an additional hose.

5. The magnetic valve and the mixing chamber

have to be assembled, that the hose is faced

downwards. (If not it could happen that the

inflow is handicapped).

6. Screw the cold water hose and the hot water

hose each with the Ypiece of the mixing cham-

ber (see drawing Drilling Jig, on page 11).

7. Screw the existing washing machine hose to

the return flow inhibitor.

8. Mount the magnetic valve via the metallic

coupler and the return flow inhibitor (which is

pre-assembled) at the cold water tap. You can

disassemble the adaptor at the water tap (see

drawing on page 10 and 11).

9. Proceed alike with the hot water tap. You

must use the delivered hose.

Service note:

Calcareous or polluted water makes casual clea-

ning of the sieve in the magnetic valves neces-

sary.

The Water inflow temperature must not

exceed 60° C!