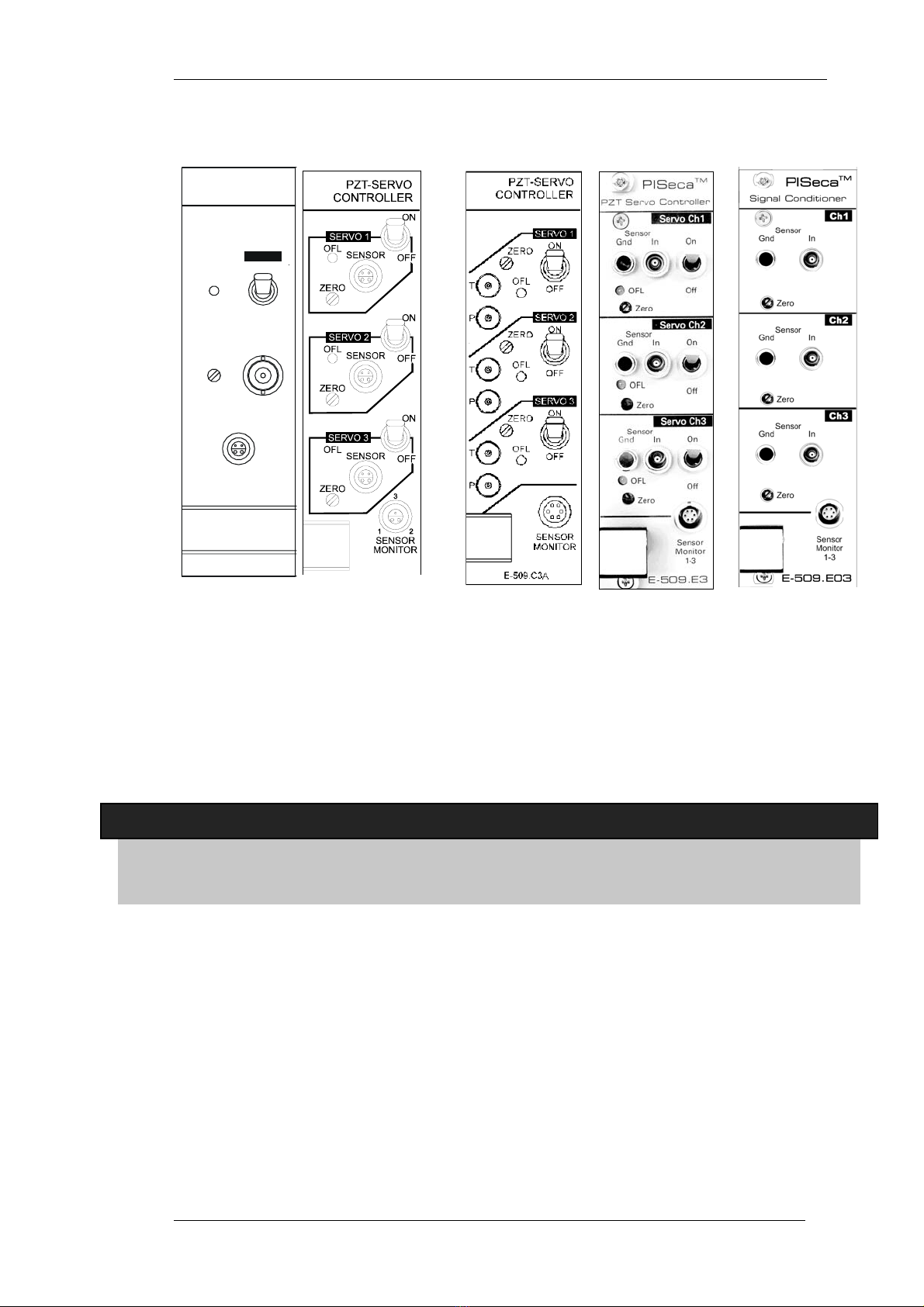

E-509 Position Servo-Control Module User Manual PZ 77E

Release 2.8.4 www.pi.ws Page 8

1.3.1. Submodules (pre-installed on the E-509TPF

2

FPT)

E-801.1x Sensor-processing submodule for SGS sensors (present on E-

509.Sx/E-509.S3S)

E-801.2x Sensor-processing submodule for LVDT sensors (present on E-509.Lx)

E-802.5x Position Servo-Control submodule (present on all except E-509.E03)

The submodules are described in separate manuals: E-801 submodules in

PZ117E, E-802.55s in PZ150E, and all former E-802.5x versions in PZ113E. The

appropriate manuals are included with your E-509 module(s).

1.3.2. Standard Accessories

E-808.90 Sensor-Monitor cable: comes with three-channel SGS- and LVDT-

sensor versions (E-509.S3, E-509.L3)

Note: The purpose of this cable is simply to split up the SENSOR

MONITOR output signal (LEMO) for the three channels. The

leads of this open ended cable are color coded:

white = channel 1,

brown = channel 2,

green = channel 3,

shield = GND.

D-893.32 Sensor-Monitor cable: comes with each capacitive-sensor version

(E-509.CxA, E-509.Ex)

Note: The purpose of this cable is simply to split up the SENSOR

MONITOR output signal (6-pin LEMO) to three separate BNC

connectors. The cable is also specially designed for low-noise

operation. The BNC connectors are each labeled with the

channel number.

3214 Banana Plug: For single-plate PISeca™

capacitive sensor reference plane ground

connection. Shown at right disassembled,

before installation of lead. Fig. 1: Banana plug

1.3.3. Single-Plate Capacitive Sensor Probes

Different size sensors are available for the E-509.E03 and E-509.E3 single-plate

capacitive sensor versions. The sensors must thus be ordered separately:

D-510.020 PISeca™ Single-Electrode Capacitive Sensor Probe, 8 mm

diameter, 20 µm nominal range, 40 µm, 50 µm and 100 µm

extended ranges, D-891.01E connecting cable included

D-510.050 PISeca™ Single-Electrode Capacitive Sensor Probe, 12 mm

diameter, 50 µm nominal range, 100 µm, 125 µm, 250 µm

extended ranges, D-891.01E connecting cable included

D-510.100 PISeca™ Single-Electrode Capacitive Sensor Probe, 20 mm

diameter, 100 µm nominal range, 200 µm, 250 µm, 500 µm

extended ranges, D-891.01E connecting cable included

See the sensor documentation for information on mounting and performance.

TP

2

PT For versions and details of the submodules, refer to the E-801 Sensor Submodule User Manual (PZ 117E)

and the E-802 User Manual (PZ150E or PZ 113E). The E-509.CxA and E-509.Ex have sensor-processing

electronics on the main module

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com