2

TABLE OF ONTENTS

Table of Contents……………………………………………………………………………………………Page 2

Introductory……………………………………………………………………………………………………..Page 3

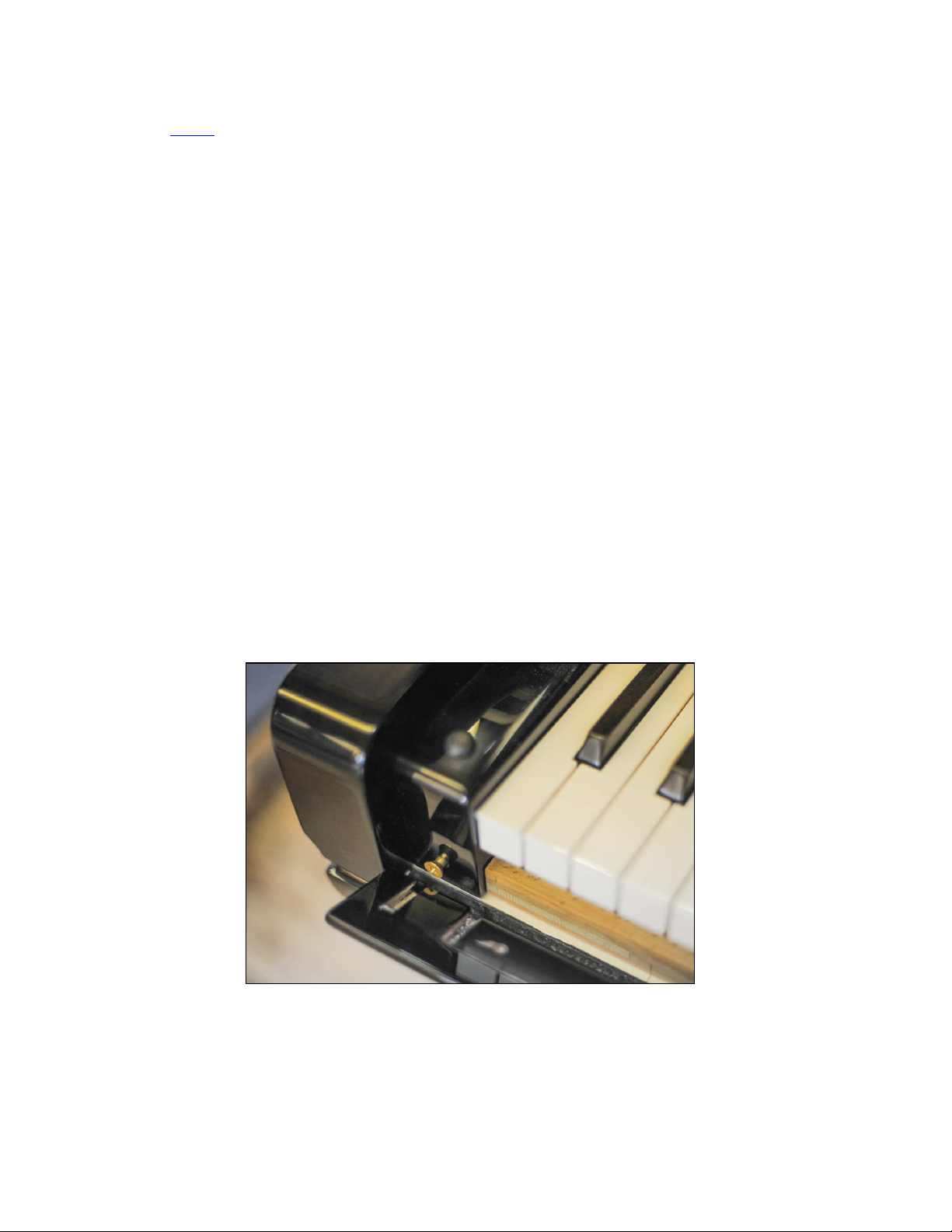

Step 1 Disassemble the Piano……………………..…………………………………………….…..Page 4

Step 2 Remove the Keybed……..…………………………….……………………………………….Page 9

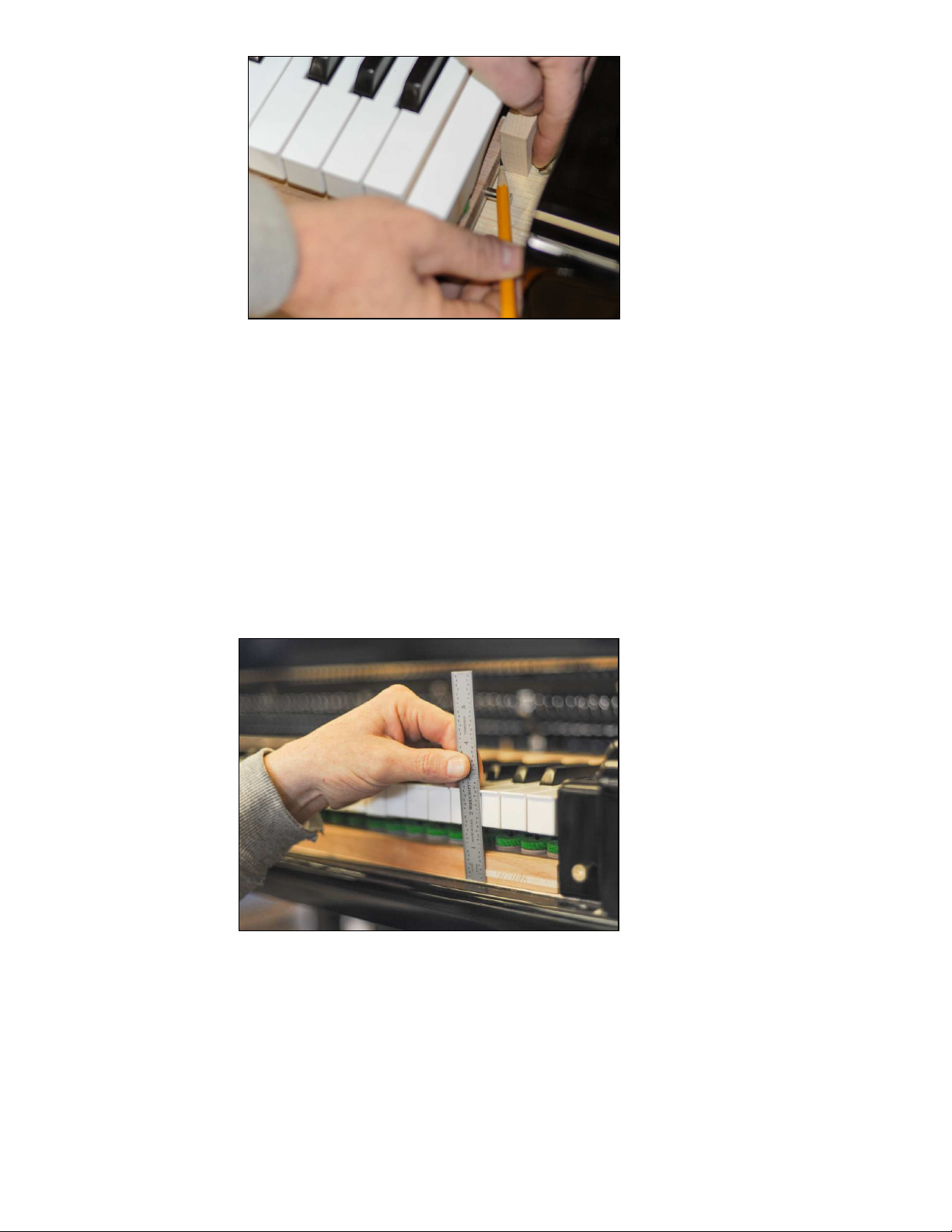

Step 3 – Measure the back key spacing for key solenoids…………………………….Page 13

Step 4 – Take keyframe measurements………………………………………………………….Page 18

Step 5 – Create back rail bead on keyframe in necessary……………………………..Page 20

Step 6 – Cut the keyframe………………………………………………………………………………Page 21

Step 7 – Mark the location of the solenoid rail slot……………………………………...Page 24

Step 8 – Prepare to cut the solenoid slot……………………………………………………….Page 28

Step 9 – Cut the solenoid slot…………………………………………………………………………Page 29

Step 10 – Reinforce the keybed………………………………………………………………………Page 32

Step 11 – Assemble tray, solenoid rails and guide solenoids ………………………..Page 32

Step 12 –Locating and installing service tool inserts…………..…………………………Page 36

Step 13– Cut legs to fit solenoid slot……………………………………………………………….Page 37

Step 14 – Installing the trap work……………………………………………………………………Page 38

Step 15 – Adjust key solenoid plungers……………………………………………………………Page 57

Step 16 – Installing key solenoids…………………………………………………………………….Page 58

Step 17 – Plug in driver boards……………………………………………………………………… Page 61

Step 18 – Setup for burn in………………………………………………………………………………Page 63

Step 19 – Burn in the unit………………………………….……………………………….……………Page 64

Step 20 – Install driver boards into the tray assembly.…..………………………………Page 64

Step 21 – Drill hole thru belly rail for wires…………………………………………………….Page 65

Step 22 – Mount CPU……………………………………………………………………………………….Page 65

Step 23 – Mount the power supply…………………………………………………………………Page 66

Step 24 – Mount power strip………………..………………………………………………………….Page 67

Step 25 – Install keybed to piano…………………………………………………………………… Page 68

Step 26 – Regulate action……………………………………..………………………………………….Page 68

Step 28 – Set up communication with the PD system……………………………………..Page 69

Step 29 – Adjust pedal solenoid……………………………………………………………………… Page 70

Step 30 – Final check list……………….…………………………………………………………………..Page 70

Step 31 – Ground strap installation…………………………………………………………………..Page 71

Appendix A – Keybed removal………………………………………………………………………… Page 72

Addendum 1 – Steinway Sostenuto…………………………………………………………………..Page 73

Addendum 2 – Keyframe modifications/shift lever……………………………………………Page 75

Addendum 3 – Sostenuto Jig………………..……………………………………………………………Page 76

LP Service Tools.………………………………………………………………………………………………..Page 77

PianoDisc Parts ID.…………………………………………………………………………………………….Page 80