3

How to use the Manual

Remark

RemarkRemark

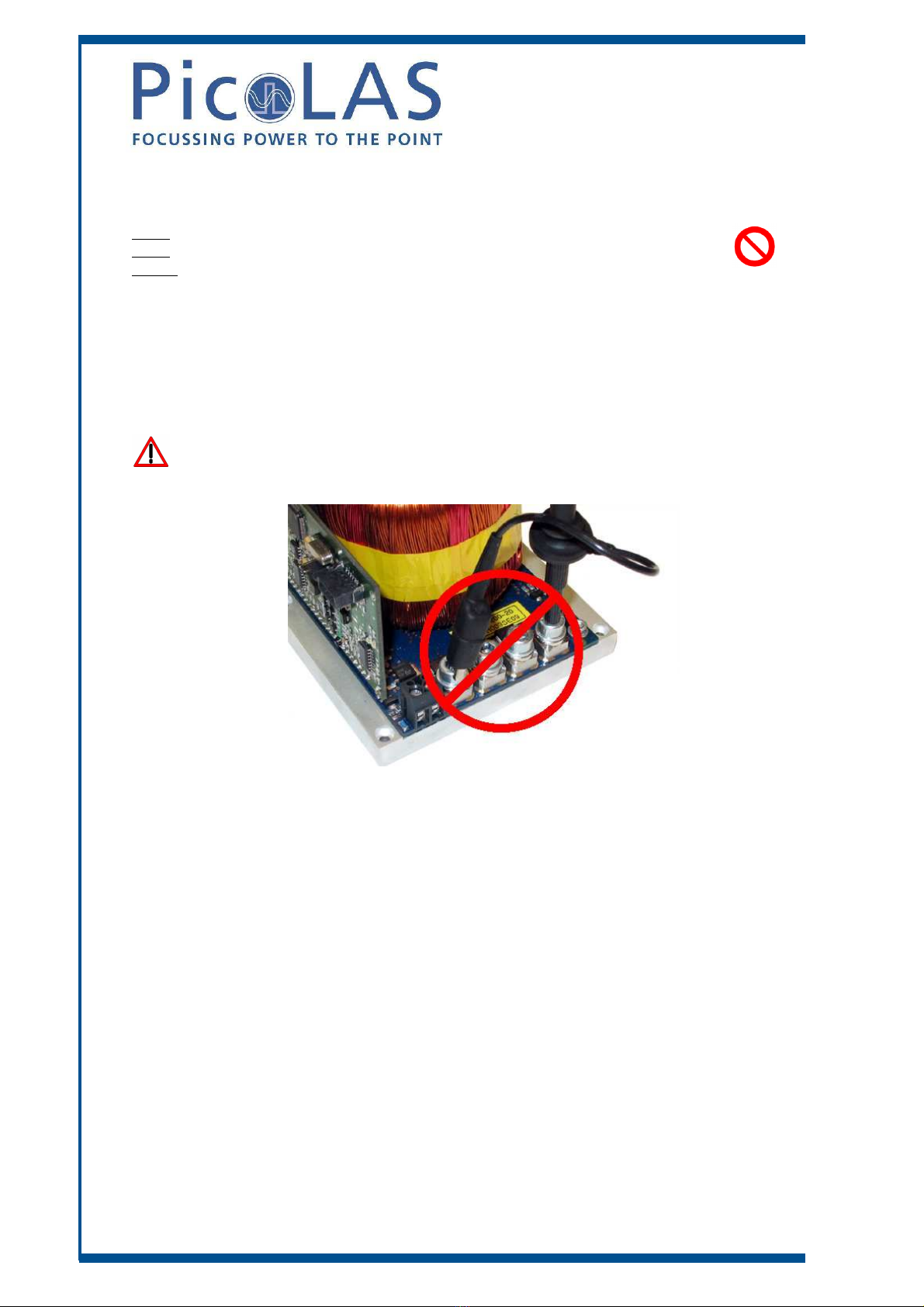

Remark: The LDP

: The LDP: The LDP

: The LDP-

--

-QCW described in this manual is a base

QCW described in this manual is a baseQCW described in this manual is a base

QCW described in this manual is a base-

--

-plate cooled laser diode

plate cooled laser diode plate cooled laser diode

plate cooled laser diode

driver. Improper cooling may cause an internal over temperature shu

driver. Improper cooling may cause an internal over temperature shudriver. Improper cooling may cause an internal over temperature shu

driver. Improper cooling may cause an internal over temperature shutdown. The two

tdown. The two tdown. The two

tdown. The two

fans in one side of the unit have to prevent local thermal hot spots inside the unit. They

fans in one side of the unit have to prevent local thermal hot spots inside the unit. They fans in one side of the unit have to prevent local thermal hot spots inside the unit. They

fans in one side of the unit have to prevent local thermal hot spots inside the unit. They

can not compensate improper base plate cooling. The air inside an enclosure within an

can not compensate improper base plate cooling. The air inside an enclosure within an can not compensate improper base plate cooling. The air inside an enclosure within an

can not compensate improper base plate cooling. The air inside an enclosure within an

OEM application is usually enough to yield enough air flow. Plea

OEM application is usually enough to yield enough air flow. PleaOEM application is usually enough to yield enough air flow. Plea

OEM application is usually enough to yield enough air flow. Please

se se

se do not cover any

do not cover any do not cover any

do not cover any

ventilation slots.

ventilation slots.ventilation slots.

ventilation slots.

Base plate cooling

Base plate coolingBase plate cooling

Base plate cooling: Depending on the final application and operation regime, this unit

: Depending on the final application and operation regime, this unit : Depending on the final application and operation regime, this unit

: Depending on the final application and operation regime, this unit

may stay none

may stay nonemay stay none

may stay none-

--

-cooled or must be assembled onto a heat sink.

cooled or must be assembled onto a heat sink. cooled or must be assembled onto a heat sink.

cooled or must be assembled onto a heat sink.

Please refer to chapter Power dissipation for more details about the

Please refer to chapter Power dissipation for more details about the Please refer to chapter Power dissipation for more details about the

Please refer to chapter Power dissipation for more details about the thermal power

thermal power thermal power

thermal power

losses during operation.

losses during operation.losses during operation.

losses during operation.

You me use a passively or an actively air/water cooled device.

You me use a passively or an actively air/water cooled device. You me use a passively or an actively air/water cooled device.

You me use a passively or an actively air/water cooled device.

Housing: All units are delivered with housing. Changes are possible; the units can be

Housing: All units are delivered with housing. Changes are possible; the units can be Housing: All units are delivered with housing. Changes are possible; the units can be

Housing: All units are delivered with housing. Changes are possible; the units can be

delivered without housing upon request.

delivered without housing upon request. delivered without housing upon request.

delivered without housing upon request.

Before powering on your u

Before powering on your uBefore powering on your u

Before powering on your unit, read this manual thoroughly and make sure your

nit, read this manual thoroughly and make sure your nit, read this manual thoroughly and make sure your

nit, read this manual thoroughly and make sure your

understood it fully.

understood it fully. understood it fully.

understood it fully.

Please pay attention to all safety warnings.

Please pay attention to all safety warnings.Please pay attention to all safety warnings.

Please pay attention to all safety warnings.

If you have any doubt or suggestion, please do not hesitate to contact us!

If you have any doubt or suggestion, please do not hesitate to contact us!If you have any doubt or suggestion, please do not hesitate to contact us!

If you have any doubt or suggestion, please do not hesitate to contact us!