Blichmann Tower of Power LTE Installation instructions

Tower LTE Owner’s Manual V5 © Blichmann Engineering, LLC 2019

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 1

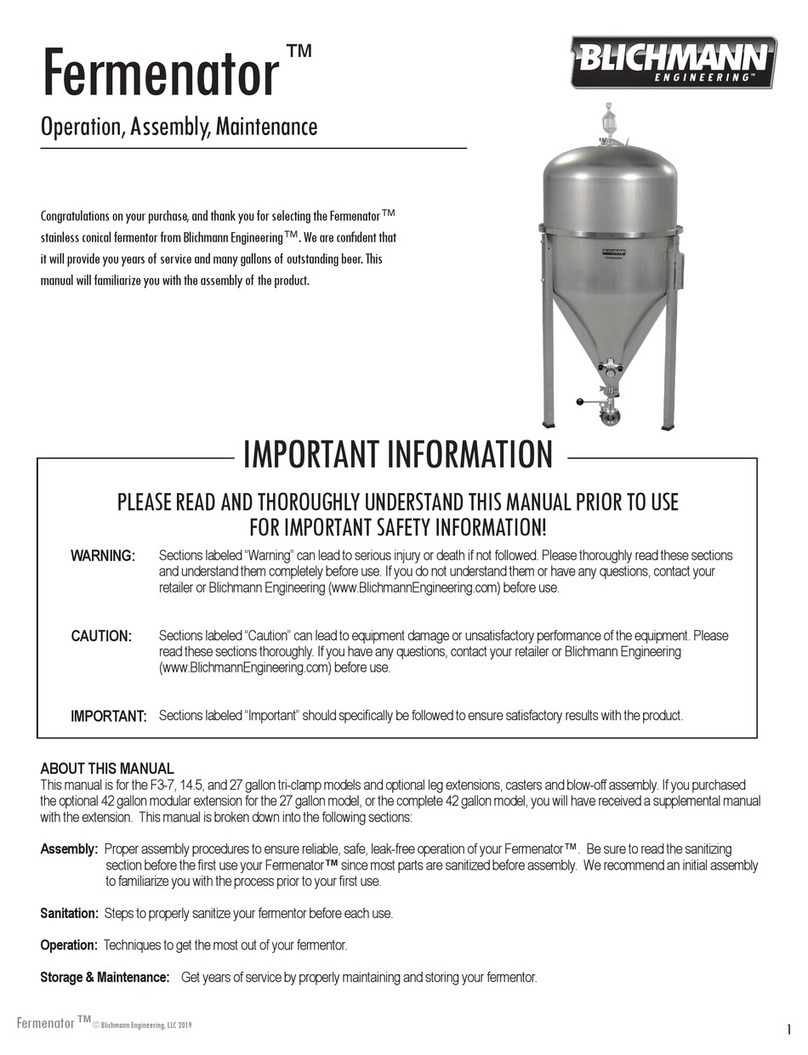

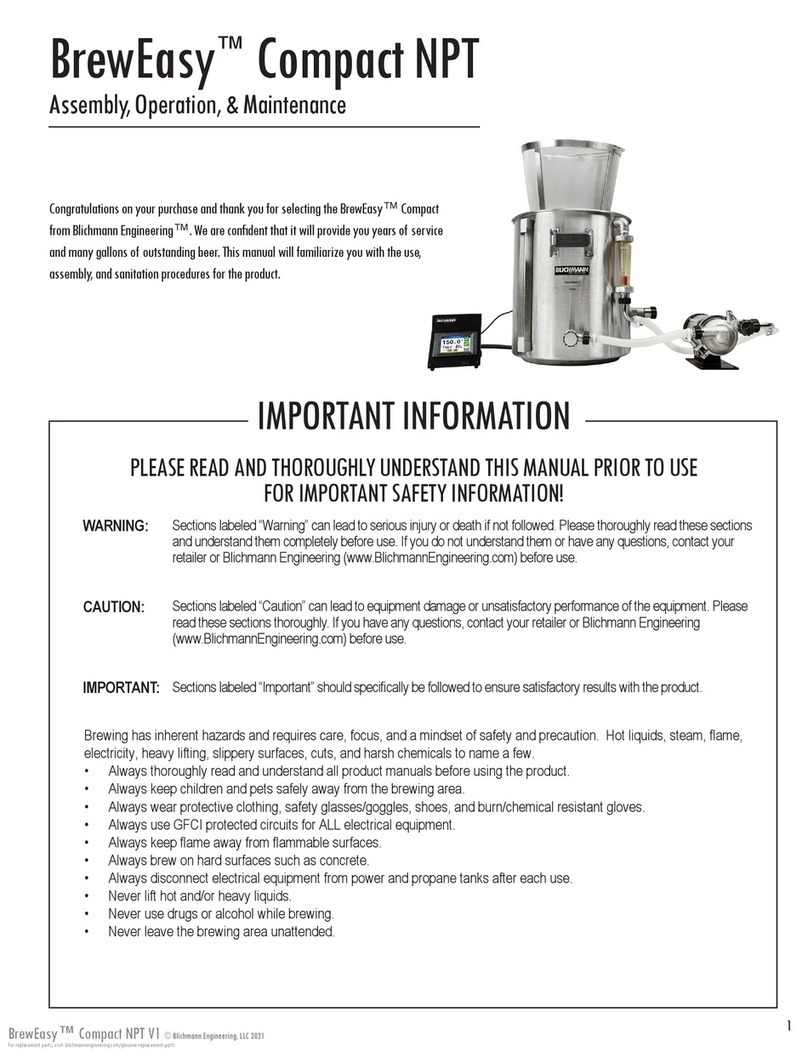

Tower of Power™ LTE

Assembly, Operation, & Maintenance

Congratulations on your purchase, and thank you for selecting the Tower of Power™ LTE

Stand from Blichmann Engineering™. We are condent that it will provide you years of

service and many gallons of outstanding beer. This manual will familiarize you with the

use, assembly, and the sanitation procedures for the product.

Sections labeled “Warning” can lead to serious injury or death if not followed. Please thoroughly read these sections

and understand them completely before use. If you do not understand them or have any questions, contact your

retailer or Blichmann Engineering (www.BlichmannEngineering.com) before use.

Sections labeled “Caution” can lead to equipment damage or unsatisfactory performance of the equipment. Please

read these sections thoroughly. If you have any questions, contact your retailer or Blichmann Engineering

(www.BlichmannEngineering.com) before use.

Sections labeled “Important” should specically be followed to ensure satisfactory results with the product.

WARNING:

CAUTION:

IMPORTANT:

IMPORTANT INFORMATION

PLEASE READ AND THOROUGHLY UNDERSTAND THIS MANUAL PRIOR TO USE

FOR IMPORTANT SAFETY INFORMATION!

Tower LTE Owner’s Manual V5 © Blichmann Engineering, LLC 2019

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 2

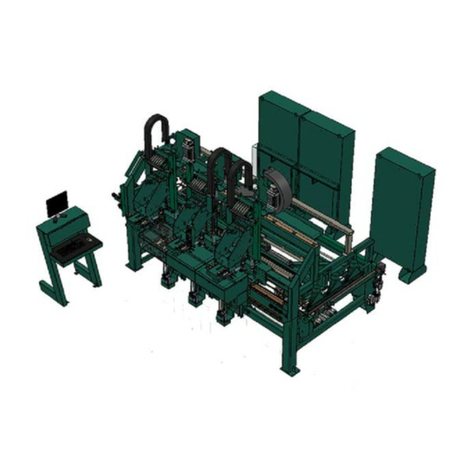

The Tower LTE Modular Brewing Control Stand is packaged unassembled to allow for more economical shipping. A list

of components included with your Tower LTE follows as well as the basic tools required for assembly. Please carefully

review the lists below to ensure you received all of the correct parts and have the required tools prior to assembly.

Base

BE-000284-00

Lower Support

BE-000286-00

Upper Support

BE-000286-00

Controller Mounting Plate

BE-000287-00

¼”-20 x ½” Bolt Stainless Steel

#10-24 x ⁄” Pan Head Screws

Stainless Steel

¼”-20 x ½” Nut Stainless Steel

SparkBox™ Mounting Kit with

mounting hardware

PARTS LIST:

Item / Part Number Quantity Item / Part Number Quantity

1

1

1

1

1

8

2

1

Temperature Sensor Fitting

BE-000268-00

¼”-20 Screw with Knob

BE-000379-00

¼”-20 Acorn Nuts Stainless

Steel

Rubber Foot

BE-000376-00

#10-24 Acorn Nuts Stainless

Steel

RipTide™ Pump

Mounting Plate Bracket

1

1

7

4

4

1

1

REQUIRED TOOLS:

7/16”Wrench x2

3/8”Wrench

PTFE Thread Seal Tape

#2 Phillips Screwdriver

Adjustable Wrench

*RipTide™ Pump include with aTOP_Tower_LTE_P models only.

ASSEMBLY:

Tower LTE Owner’s Manual V5 © Blichmann Engineering, LLC 2019

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 3

Install the four rubber feet in the four holes in the

base using with the supplied #10-24 acorn nuts. Be

sure to orient the rubber portion of the feet on the

side of the base without threaded studs. Next, install

the lower support on the threaded studs of the base

indicated in Figure 1. Install and tighten three of the

¼”-20 acorn nuts and tighten. Last, install the upper

support in the lower support and install and tighten

the ¼”-20 screw with knob as shown in Figure 1.

Important:

Install the BrewCommander™ brewhouse control

module on the controller mounting plate first using

four of the supplied #10-24 screws!

After the brewing control module is attached to

controller mounting plate, attach the mounting plate

to the upper support with the remaining four #10-24

screws.

Step One:

Figure 1

Step Two:

Important:

Be sure to install the pump with the pump head on

the left-hand side of the Tower LTE assembly.

Install the pump with the supplied ¼”-20 acorn nuts

as shown in Figure 3.

Figure 2

Step Three:

Figure 3

Tower LTE Owner’s Manual V5 © Blichmann Engineering, LLC 2019

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 4

Important:

Remove the RipTide™ Pump head prior to installing the Tem-

perature Sensor Fitting.

Caution:

Apply two to three wraps of PTFE thread seal tape to

the male threads of the linear flow valve and install the

Temperature Sensor Fitting on the linear flow valve.

Hand tighten the fitting and use a wrench if necessary

to orient the fitting as shown in Figure 5. DO NOT OVER

TIGHTEN the temperature sensor fitting. Galling of

stainless steel threads is not covered by your warranty.

Install the temperature sensor as described in the Tower

of Power™ controller manual.

Note:

If using March or Chugger pump we recommend using

a valve on the pump (part# aBall_valve_MXF_12NPT)

Figure 4

Step Four:

MOUNTING THE SPARKBOX™

The SparkBox™ is used for gas BrewCommander™

controllers. Use the directions below to mount your

SparkBox™ to the Tower of Power LTE stand.

Attach the bracket to the upper support (Figure 5) with

the ¼”-20 x ½” bolts and ¼”-20 nuts as shown in Figure 6.

Attach the SparkBox™ mounting plate with the #6-32 x 3/8

Phillips pan head screw and #6-32 nut as shown in Figure

7. Attch the SparkBox™ to the SparkBox™ mounting plate

with the ¼-20 x ½ stainless cap screws and ¼-20 nuts as

shown in Figure 8 and Figure 9.

Figure 5 Figure 6

Figure 7

Figure 8

Figure 9

Tower LTE Owner’s Manual V5 © Blichmann Engineering, LLC 2019

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 5

OPTIONAL ACCESSORIES

Install the chiller bracket with the two 1/4”-20 x 1/2” bolts

and nuts as shown in Figure 10.

Step One:

Install the Therminator™ chiller to the Quick Release Bracket

and hook onto the mounting plate as shown in Figure 11.

Figure 10

Figure 11

Step Two:

Quick Release Bracket and Terminator™

Tower LTE Owner’s Manual V5 © Blichmann Engineering, LLC 2019

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 6

Compact Conguration

The Tower LTE™ can be operated as assembled in the expanded configuration, or it can be collapsed to its compact

configuration. The compact configuration is also convenient for storage between brewing sessions. The Tower LTE™

can be stowed away in a 20 gallon, or larger, BoilerMaker™ Brew Kettle when not in use.

To arrange the Tower LTE™ in its compact configuration, remove the ¼”-20 Screw with knob and separate the upper

support from the lower support. Rotate the upper support with controller 180° as shown in Figure 12 and Figure 13.

Figure 12 Figure 13

Important: Operating the RipTide™ pump requires that the pump be

located at the lowest point in your system. Locate the pump such that

the bottom of the vessel supplying the pump is above the pump inlet.

Caution: Failure to properly locate the pump can cause damage to the

pump impeller and housing. Damage to the pump due to improper

location or any other misuse is not cover by your warranty.

The RipTide™ pump installed on the Tower LTE™ can be used to circu-

late and transfer hot water or wort during your brew sessions, and the

linear flow valve can be used to regulate the flow rate. Always control

the flow rate on the outlet of the RipTide™ pump. Never restrict the

inlet of the pump, this will result in poor performance and possible

damage to your pump. (see Figure 14)Figure 14

Pump Inlet

Pump Outlet

Flow Control Valve

Pump Operation

Tower LTE Owner’s Manual V5 © Blichmann Engineering, LLC 2019

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 7

Maintenance / Cleaning

Important: The Tower LTE™ Modular Controller Stand and accessories require routine maintenance after use. Before

cleaning, unplug and disconnect the BrewCommander™ and all accessories from any and all power sources.

Caution: The Tower LTE™ Modular Controller Stand and the BrewCommander™ brewhouse control can be cleaned

with a damp cloth and mild detergent. Never spray the BrewCommander™ controller directly with any liquid.

Caution: NEVER submerge the temperature sensor in any liquids!

The RipTide™ pump head and temperature sensor fitting should be cleaned after each use with a cleaner such as Five

Star Chemicals’PBW, following all manufacturer’s instructions. Disassembly of the pump head and temperature sensor

fitting is not necessary for every cleaning. PBW or similar cleaning solution, subsequent rinse water, and sanitizer, such

as StarSan, can be recirculated to facilitate easier cleaning and sanitation of the Tower LTE Modular Controller Stand’s

plumbing, however, the pump head assembly and fittings should be disassembled, cleaned, and reassembled every

five to six brew sessions. Refer to the RipTide™ manual for information on assembly and disassembly.

A. Limited Warranty

1. Blichmann Engineering warrants to the original purchaser that this product will be free from manufacturing defects in material and workmanship for a period of one (1) year from the date of purchase by the customer. Proof of

purchase is required. Blichmann Engineering’s obligation to repair or replace defective materials or workmanship is the sole obligation of Blichmann Engineering under this limited warranty.

2. This product is for home use only. The limited warranty covers only those defects that arise as a result of normal use of the product and does not cover any other problems, including, but not limited to, those that arise as a

result of:

a. Improper maintenance or modication;

b. Damage due to incorrect voltage or improper wiring by customer;

c. Operation outside of the product’s specications;

d. Carelessness or neglect to operate the product in accordance with instructions provided with the product;

e. Damaging the tamper label on the product;

f. Damage by over-tightening the fasteners;

g. Failure to follow cleaning and / or maintenance procedures; or

h. Exceeding published operational temperatures.

3. Blichmann Engineering reserves the right to request delivery of the defective component for inspection before processing the warranty claim. If Blichmann Engineering receives, during the applicable warranty period, notice

of a defect in any component that is covered by the warranty, Blichmann Engineering shall either repair or replace the defective component with a new or rebuilt component at Blichmann Engineering’s option.

4. Blichmann Engineering must be notied within seven (7) days of the delivery date of any shipping damage. Customer is responsible for shipping damage outside of this time period. Approval for return must be provided by

Blichmann Engineering prior to any return. Customer is responsible for keeping all original packaging material for warranty returns. Blichmann Engineering is not responsible for damage from improperly packaged warranty

returns, and these repair costs will be the sole responsibility of the customer. Shipping costs for warrantee returns are covered only for the contiguous United States.

5. Blichmann Engineering’s limited warranty is valid in any country where the product is distributed.

________________________________________

B. Limitations of Warranty

1. Any implied warranty that is found to arise by way of state or federal law, including any implied warranty of merchantability or any implied warranty of tness, is limited in duration to the terms of this limited warranty and is

limited in scope of coverage to this warranty. Blichmann Engineering disclaims any express or implied warranty, including any implied warranty of tness for a particular purpose or merchantability, on items excluded from

coverage as set forth in this limited warranty.

2. Blichmann Engineering makes no warranty of any nature beyond that contained in this limited warranty. No one has authority to enlarge, amend, or modify this limited warranty, and Blichmann Engineering does not authorize

anyone to create any other obligation for it regarding this product.

3. Blichmann Engineering is not responsible for any representation, promise, or warranty made by any independent dealer or other person beyond what is expressly stated in this limited warranty. Any selling or servicing dealer

is not Blichmann Engineering’s agent, but an independent entity.

________________________________________

C. Limitations of Liability

1. The remedies provided in this warranty are the customer’s sole and exclusive remedies.

2. Except for the obligations specically set forth in this warranty, in no event shall Blichmann Engineering be liable for direct, indirect, special, incidental, or consequential damages, whether based on contract, tort, or any other

legal theory and whether or not advised of the possibility of such damages.

3. This warranty does not cover, and in no event shall Blichmann Engineering be liable for, travel, lodging, or any other expense incurred due to manufacturing defects in material and workmanship, or any other reason.

4. Any performance of repairs after the warranty coverage period has expired or performance of repairs regarding anything excluded from coverage after this limited warranty shall be considered good-will repairs and they will

not alter the terms of this limited warranty, or extend any warranty coverage period.

5. Venue for any legal proceedings relating to or arising out of this warranty shall be in Tippecanoe County, Indiana, United States, which courts will have exclusive jurisdiction.

________________________________________

D. Local Law

1. This warranty gives the customer specic legal rights. The customer may also have other rights that vary from state to state in the United States or other countries.

2. To the extent that this warranty is inconsistent with local law, it shall be deemed modied, only to the extent necessary to be consistent with such local law.

This product uses FDA and/or NSF approved food grade materials anywhere the product touches the beverage.

Warning: This product contains or may contain chemical(s) known to the State of California to cause cancer, birth defects, or other reproductive harm.

Blichmann Engineering Product Warranty

Table of contents

Other Blichmann Industrial Equipment manuals