Toro Workman 07224-90001 Instruction Manual

MODEL NO. 07224-90001 & UP

MODEL NO. 07223-90001 & UP

MODEL NO. 07269-90001 & UP

OPERATORS, SET-UP,

AND PARTS

CATALOG

INDUSTRIAL WORKMAN®KIT

FORM NO. 99-0744

©The TORO Company - 1999

All Rights Reserved

To assure maximum safety, optimum

performance, and to gain knowledge of the

product, it is essential that you or any other

operator of this Vehicle read and understand

the contents of this manual before the engine

is ever started. Pay particular attention to the

SAFETY INSTRUCTIONS highlighted by the

triangular safety alert symbol.

The safety alert symbol means CAUTION,

WARNING or DANGER - personal safety

instruction. Failure to comply with the

instruction may result in personal injury.

Keep this Operators Manual in the plastic tube behind the operator seat.

It is very important that all persons operating this equipment have easy access to these instructions at all

times!

Carefully read and follow the Maintenance Instructions that are provided with this equipment and the

Safety Instructions in the Workman®Vehicle Operators Manual.

SAFETY INSTRUCTIONS

RECOGNIZE SAFETY INFORMATION

This safety-alert symbol is used to call

attention to a dangerous situation, which

could result in serious injury or death to the operator

or a bystander.

Safety, mechanical and some general information

in this manual are emphasized. DANGER,

WARNING and CAUTION identify safety

messages. Whenever the triangular safety symbol

appears, it is followed by a safety message that

must be read and understood. For more details

concerning safety, read the Safety Instructions on

this page and page 2. IMPORTANT identifies

special mechanical information andNOTE identifies

general information worthy of special attention.

These instructions are provided as a guide for the

safe operation and maintenance of this equipment.

However, the operators personal safety, as well as

those persons in the work area, will depend on the

careful actions and good judgement of the operator.

To reduce the potential for injury or death,

comply with the following safety instructions.

BEFORE OPERATING:

1. Operate this machine only after reading and

understanding the contents of this manual and

the Workman®Vehicle Operators manual. A

replacement manual is available by sending

complete model and serial number to:

Hahn Equipment Co., 1625 N. Garvin St.,

Evansville, IN 47711.

2. Keep all shields, safety devices and decals in

place. If a shield, safety device or decal is

malfunctioning, illegible or damaged, repair or

replace it before operating the machine.

TOWING AT EXCESSIVE SPEEDS COULD

CAUSE VEHICLE TO LOSE STEERING

CONTROL.

Never tow vehicle faster than 5 MPH

(8 km/h).

Never exceed maximum tongue weight

of 400 LBS (181 KG.).

Never exceed maximum trailer weight

Without trailer brakes

1500 LBS (680 KG.)

With trailer brakes

3500 LBS (1587 KG.)

Read, understand, and follow Safety

Instructions below and in Workman

Operators Manual before operating

vehicle.

IMPROPER TOWING WITH THIS VEHICLE

MAY CAUSE SERIOUS PERSONAL INJURY

OR DEATH.

WARNING

2

1

1

SAFETY INSTRUCTIONS

BED REMOVAL PROCEDURE:

6. For removal of the cargo bed to preform engine

service, adhere to the following procedure:

A. Stop the Vehicle and set the parking brake.

B. Shut off the vehicles engine and remove

key from ignition.

WHILE OPERATING:

3. Always follow Workman®Vehicle operating

instructions in Workman®Vehicle Operators

Manual.

4. DO NOT OVERLOAD THE VEHICLE. Never

exceed maximum Operator and Pay Load

Capacity of 1800 lb and maximum Gross Vehicle

Weight of 4000 lb. Failure to position loads

carefully can result in their shifting or tipping over.

Distribute loads evenly, as low as possible, with

center of gravity forward of rear axle. Secure load

using Lifting Lugs (Figure 3).

5. Make certain everyone is clear of the machine

before loading or starting the engine to move the

vehicle.

6. Before backing up, look to the rear and assure

no one is behind. Back up slowly.

C. Disengage all power and wait until all

moving parts have stopped.

D. Remove all cargo.

E. Remove welding gas bottles (if equipped)

F. Remove beds Front Securing Bolts,

shown in Figure 1.

G. Remove Rear Securing Pins, shown in

Figure 2.

FIG. 1

1. Front Securing Bolt

FIG. 2

1. Rear Securing Pin

Base Weight for Bed of Industrial

Workman®kit is 350 lb.

Always be sure Lifting device is capable

of lifting bed and any attached accessory

to avoid personal injury or death.

WARNING

H. Lift the cargo bed from four corners evenly

from the vehicles frame, using Lifting

Lugs as shown in Figure 3, and set aside.

Do not exceed capacity. Maximum

capacity of operators, attachments and

cargo is 1800 LB (4000 LB. GVW)

or 800Kg (1800Kg GVW).

Always distribute cargo load evenly on

bed with center of gravity of load forward

of rear axle.

WARNING

3

HITCH RATING

MAXIMUM TONGUE WEIGHT:

400LBS (181KG.)

MAXIMUM TRAILER WEIGHT:

WITHOUT TRAILER BRAKES;

1500 LBS (680KG.)

WITH TAILER BRAKES;

3500 LBS (1587 KG.)

92-2724

ON AXLE TUBE

(Part No. 92-2724)

SAFETY & INSTRUCTION DECALS

The following safety and instruction decals are installed on the INDUSTRIAL WORKMAN®KIT. If

any become damaged or illegible, replace them. Decals and part numbers are listed below and in

the parts catalog. Order replacements from your Authorized Toro Distributor.

SAFETY INSTRUCTIONS

Four corners of Industrial Bed

(Part No. 99-0488)

I. When service is complete, reinstall the

cargo bed in its original position and

secure with the pins at the rear and the

bolts at the front. Refer to Torque Specs.

8. Keep all nuts, bolts and other fasteners

tightened securely. Replace any shields removed

during servicing or adjustments.

9. To be sure of optimum performance and safety,

always purchase genuine TORO replacement

parts and accessories. Replacement parts and

accessories made by other manufacturers could

be dangerous. Altering this equipment in any

manner may affect the machines operation,

performance, stability, durability or its use may

result in personal injury or death. Such use could

void the product warranty by the TORO Company.

FIG. 3

1. Lifting Lugs

1

4

SERVICE INSTRUCTIONS:

1. Instructions for vehicle engine service

A. Diesel Unit:

1. Check oil on lower right side of engine

without lifting the cargo bed.

2. Add oil to engine through Access Door

in bed. See Figure 4.

1

2

1

2

FIG. 4: Diesel Engine

1. Access door 2. Oil fill cap

B. Gasoline and Liquid Propane Gas units:

Check oil and add oil through Access Door

in bed. See Figure 5.

MAINTENANCE

FIG. 5: Gas/Liquid Propane Gas Engine

1. Oil filler cap 2. Oil check stick

Never lift entire vehicle by the bed Lifting

Lugs.

Never pivot bed on rear pins.

Remove all securing pins and bolts and

remove bed for service.

Always remove all cargo (including

welding gas bottles) before removing

bed.

Always lift bed at all four corners.

Do not exceed capacity. Maximum

capacity of operators, attachments and

cargo is 1800 LB (4000 LB. GVW)

or 800kg (1800kg GVW).

Always distribute cargo load evenly on

bed with center of gravity of load forward

of rear axle.

Read, understand, and follow Safety

Instructions and Bed Removal Procedure

before servicing vehicle.

IMPROPER USE OF THE CARGO BED MAY

CAUSE SERIOUS PERSONAL INJURY OR

DEATH.

WARNING

5

C. For all engine bay service requiring the

removal of the cargo bed, adhere to the

previous removal procedures in Maintenance

Safety Instructions on Page 2.

D. Refer to Workman® Operators Manual for

service instructions.

2. Installation of welding gas bottles (for units

equipped with optional Acetylene Tray Kit Model

07224). See page 9 for SET-UP instructions

of Acetylene Tray Kit.

A. Remove cover plate from industrial bed.

B. Remove fasteners securing the Bottle

Restraint Plate at the front left corner of the

cargo bed and set plate aside.

C. Place Oxygen and Acetylene Bottles onto

the Bottle Tray as shown in Figure 5. Tray is

designed for a 38 High Acetylene Tank with

a diameter of 8 1/2 and a 48 high Oxygen

Tank with a diameter of 7 1/2.

D. Secure the bottles to the bed with the bottle

restraint plate. Reinstall 1/2 Flange Lock

fasteners using a torque load of 75 ftlb

(102 Nm). FIG. 5

1. Oxygen and Acetylene Bottles

2. Bottle Restraint plate 3. Optional Bottle Tray

MAINTENANCE

1

2

3

TORQUE SPECIFICATIONS

Bolt Size ftlb Nm

1/4 100 1125

Bolt Size inlb Ncm

3/8

1/2

30

75

41

102

6

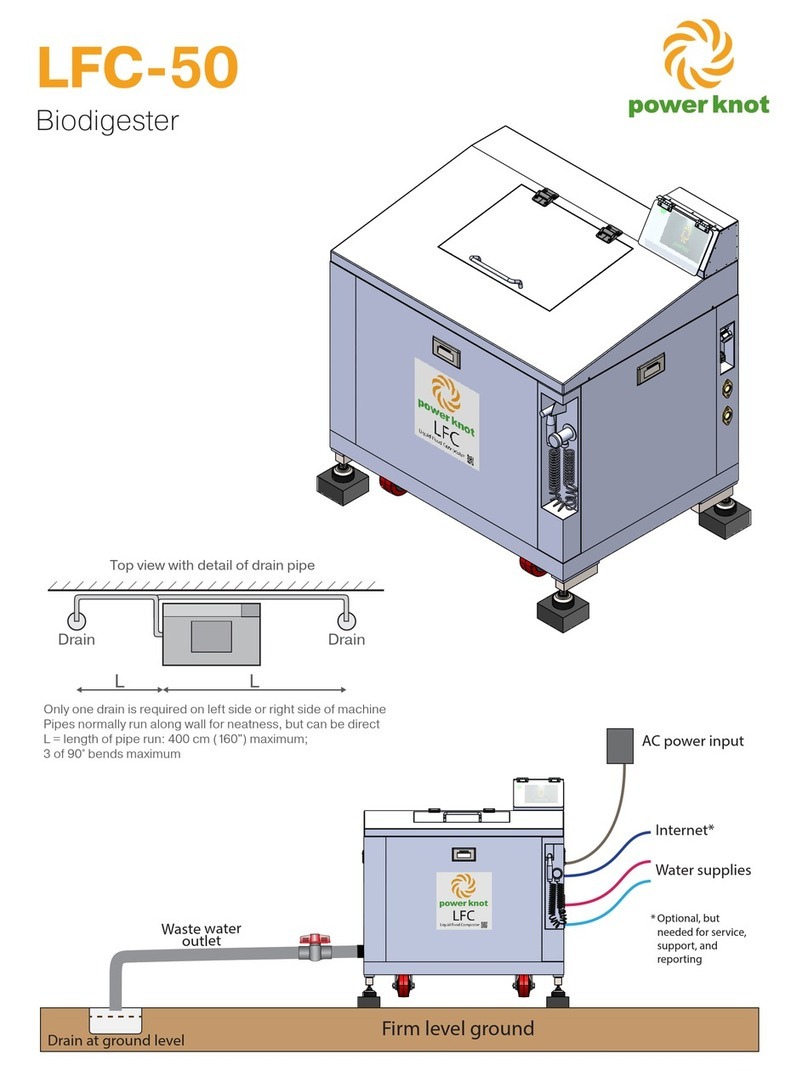

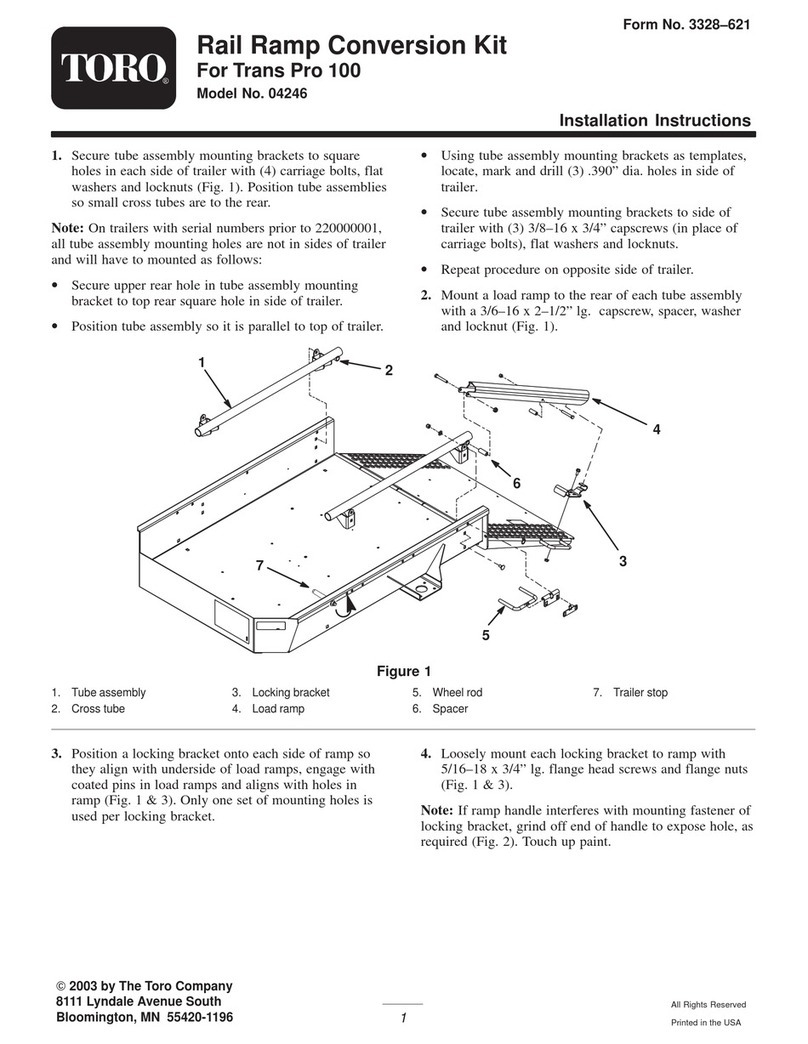

BUMPER ASSEMBLY 99-0805:

1. The two (92-2700) Hitch Arm Brackets are to

be installed on the Rear Channels of the

Workman® unit. The short leg of Bracket

(channel) should be at the top. See FIG. 1.

Using four (two for each bracket) 3/8-16 x 1

Lg. Flange Lock Hex. Hd. Cap Screws, mount

Brackets to the Workman®units channels.

Tighten screws securely with four 3/8 Flange

Lock Nuts.

2. Slide (99-0468) Bumper Assembly between

Rear Channels of the Workman®unit. Mount

(99-0468) Bumper Assembly to the (92-2700)

Hitch Arm Brackets installed in Step 1. Using

two (one for each side) 1/2-13 x 1-1/2 Lg. Hex.

Hd. Cap Screws, insert screws through the larger

holes in Bumper and larger holes in Hitch Arm

Bracket. Place a 1/2 Flange Lock Nut on each

screw. Do not tighten screws completely at this

time. Insert two (one on each bracket) 3/8-16 x

1-1/2 Lg. Hex Hd. Cap Screws through the

smaller holes in Bumper and smaller holes in

Hitch Arm Bracket. Place a 3/8 Flange Lock

Nut on each screw. Do not tighten screws

completely at this time. See FIG. 1.

3. Using two (92-2752) U-Bolts, (one for each

side) wrap the U-Bolts around the Transaxle

Support Tube on the Workman®unit. Insert the

threaded ends of the U-Bolts through Welded

Brackets on the Bumper Assembly. Using four

(two for each U-Bolt) 3/8 Flange Lock Nuts,

equally tighten each side of the U-Bolts securely.

See FIG. 2. Securely tighten the four screws and

nuts on the Hitch Arm Brackets previously

installed in Step 2. The Bumper Assembly is now

complete.

SET-UP

NOTE: Right, Left, Front, and Rear are

referenced while seated in the operators

position.

NOTE: Refer to Torque Specifications on page

5 for all Fasteners.

Refer to the Illustrated Parts List for the details of

parts used in assembling the Industrial

Workman®kit.

FIG. 1

1. Hitch Arm Bracket (Short leg) 2. Bumper Assembly

1641

1

2

FIG. 2

1. U-Bolt 2. Transaxle Support Tube

1642

1

2

7

4. Lift (99-0465) Skid Plate up to the (99-0466)

Adjustment Plate. Mount the two Plates together

using two 3/8-16 x 1 Lg. Flange Lock Hex.

Hd. Cap Screws and 3/8 Flange Lock Nuts. The

Assembly is now complete.

SKID PLATE ASSEMBLY 99-0806:

(Requires 99-0805 Bumper Assembly)

1. Mount (99-0465) Skid Plate to Bumper

Assembly, using two 3/8-16 x 1 Lg. Flange

Lock Hex. Hd. Cap Screws. Slide the two screws

through the welded Bumper Bracket and through

the two Skid Plate mounting holes. See

Illustration on page 11, (Model No. 99-0805 and

99-0806) Items 1 and 3. Loosely place a 3/8

Flange Lock Nut on each screw.

2. The (99-0466) Adjustment Plate can be located

in two different places on the Skid Plate. The

mounting depends on which type of unit you are

installing the Adjustment Plate on. The Gasoline

units Adjustment Plate is located all the way to

the right on the Skid Plate. The Diesel units

Adjustment Plate is located all the way to the left.

See Illustration on page 11, (Model No. 99-0806)

Item 2.

3. Making sure (99-0466) Adjustment Plate has

the welded nuts up toward the unit, slide

Adjustment Plate over the Workman®units Oil

Pan Guard, (this Guard has two holes for

mounting the Adjustment Plate) secure it into

place using two 3/8-16 x 5/8 Lg. Hex. Hd. Cap

Screws. IMPORTANT: Make sure these

screws are not too long and do not rupture

the oil pan when tightening. See FIG. 3.

Tighten all screws and nuts securely.

TANK GUARD ASSEMBLY:

1. Position Tank Guard over the Fuel Tank. Using

three 3/8-16 x 1 Lg. Flange Lock Hex. Hd.

Cap Screws to mount the Tank Guard Assembly,

place the screws into the three existing insert

holes in Workman®unit. These existing inserts

are located behind the Fuel Tank on the Rear

Channel (Frame) of the Workman® unit. See FIG.

4. Tighten screws securely.

2. Install (99-0463) Guard Brace Strap with the

3/8-16 x 1 Lg. Flange Lock Hex. Hd. Cap Screw

and 3/8 Flange Lock Nut. Attach the Guard

Brace Strap on top of bottom panel of Tank

Guard. Slide the screw through Strap and

through Tank Guard. See Illustration on page

10, Items 5 and 6. Tighten nut onto screw, leaving

nut finger tight. The other end of the Strap should

be attached to the bottom Channel of the

Workman®

unit. Using a 3/8-16 x 1 Lg. screw,

slide screw through the Workman® unit Channel

and through the Strap, then place nut on screw.

Securely tighten both screws and nuts holding

the Strap. The Assembly is now complete.

SET-UP

FIG. 3

1. Adjustment Plate 3. Oil Pan Guard

2. Skid Plate 4. Welded Nut

1643

2

4

3

1

NOTE: Refer to Torque Specifications on page

5 for all Fasteners.

NOTE: Refer to Torque Specifications on page

5 for all Fasteners.

FIG. 4

1. Tank Guard Assy 3. Fuel Tank

2. Existing Inserts Location

1644

1

2

3

8

5. Secure (92-2667) Attachment Mount Brackets

to (99-0433) Flatbed Assembly using two 1/2-

16 x 1- 1/2 Lg. Flange Lock Hex. Hd. Cap Screws

and two 1/2 Flange Lock Nuts. Make sure

Attachment Mount Brackets are flush with

Mounting Brackets on Flatbed Assembly. See

FIG. 6. Tighten the six screws and nuts securely,

at this point the Bed should be secure to the

Workman®unit.

Base Weight for Bed of Industrial

Workman®kit is 350 lb.

Always be sure Lifting device is capable

of lifting bed and any attached

accessory to avoid personal injury or

death.

l

l

l

BED ASSEMBLY 07269:

1. Install four (99-9719) Wear Blocks on the

Flatbed Assembly using eight (two for each

Block) 1/4-20 x 3/4 Lg. Plain Hd. Screws and

eight 1/4 Flange Lock Nuts. See Illustration on

page 10, (Model No. 07269) Items 2, 3 and 4.

Tighten screws securely. The screw heads

should be recessed into the Wear Blocks holes.

2. Attach four (99-0451) Rear Pin Plates on the

(99-0433) Flatbed Assembly using four 1/2-13 x

4 Lg. Hex. Hd. Cap Screws and four 1/2 Flange

Lock Nuts. The flat part of the plate should be

toward the back of the Flatbed Assembly. See

Illustration on page 10, (Model No. 07269) Item

21. Finger tighten screws and nuts.

3. Remove the four existing (two each side)

1/2-16 x 1- 1/4 Lg. Flange Lock Hex. Hd. Cap

Screws in the Workman®unit. See FIG. 5.

Install two (99-2667) Attachment Mount Brackets

by using the same four 1/2 Flange Lock Hex.

Hd. Cap Screws and 1/2 Flange Lock Nuts that

were removed. Finger tighten screws and nuts.

4. Lower (99-0433) Flatbed Assembly onto the

Workman®unit, making sure Rear Pin Plates (99-

0451) clear the channel on the Workman®unit.

After positioning bed on unit, slide two (92-1233)

Clevis Pins through the Rear Pin Plates (99-0451)

and through the Workman®units Rear Channel

(Rail). Lock (92-1233) Clevis Pins into place by

using four (92-1298) Lynch Pins. Tighten Rear

Pin Plates securely.

SET-UP

WARNING

Lift the cargo bed from four corners

evenly, using Lifing Lugs.

NOTE: Refer to Torque Specifications on page

5 for all Fasteners.

Always remove all cargo (including

welding gas bottles) before lifting bed.

Never lift entire vehicle by the bed

Lifting Lugs.

l

Never pivot bed on Rear Pins.

l

Do not exceed capacity. Maximum

capacity, attachments and cargo is 1800

LB (4000 LB. GVW) or 800kg (1800

GVW).

l

Read, understand, and follow Safety

Instructions and Bed Removal

Procedure before servicing vehicle.

FIG. 5

1. Attachment Mount Bracket

2. Existing 1/2 Flange Lock Hex. Hd. Cap Screw

3. Bottle Tray Kit Assy (For Reference Only)

3

1645

1

2

FIG. 6

1. Attachment Mount Bracket

2. 1/2 x 1- 1/2 Lg. Flange Lock Hex Hd. Cap Screw

3. Flatbed Mounting Bracket

1646

3

2

1

9

TRAY KIT ASSEMBLY 07224:

1. Remove the (99-0453) Bottle Restraint

Assembly from the Flatbed Assembly by

removing the center 1/4 Flange Lock Nut from

the 1/4 x 3/4 Lg. Hex. Hd. Cap Screw that

secures the (99-0455) Cover Plate Assembly to

the Bottle Restraint Assembly. Remove the two

1/2 x 1-1/2 Lg. Flange Lock Hex. Hd. Cap

Screws from each end of the Bottle Restraint

Assembly. Set the Bottle Restraint Assembly

aside for future use.

2. Remove the (99-0455) Cover Plate Assembly

from the (99-0433) Flatbed Assembly by sliding

the Cover Plate out.

3. Mount (99-0476) Bottle Tray to the Workman®

unit using two 3/8-16 x 1 Lg. Flange Lock Hex.

Hd. Cap Screws. Insert screws through the two

holes in the top of Bottle Tray and into existing

inserts in the Workman®units Rear Channel.

See FIG. 7. Tighten screws securely.

4. Slide two 3/8-16 x 1 Lg. Flange Lock Hex.

Hd. Cap screw through the lower two holes in

Bottle Tray and through the two holes in (99-0480)

Tray Support Strap. Using two 3/8 Flange Lock

Nuts and the screws secure Strap to Bottle Tray.

See Illustration on page 10, (Model No. 07224)

Items 7 and 8.

and reattach nut. Tighten securely. If unit does

not have the (99-0463) Guard Brace Strap, then

use one 3/8-16 x 1 Lg. Flange Lock Hex. Hd.

Cap Screw and one 3/8 Flange Lock Nut to

connect Tray Support Strap to the Workman®

units lower Brace (Channel). Using one 3/8-

16 x 1 Lg. Flange Lock Hex. Hd. Cap Screw,

slide screw through the Workman®units Lower

Brace and through the center hole in the Tray

Support Strap. Place a 3/8 Flange Lock Nut onto

screw and tighten securely.

6. Place Oxygen and Acetylene Bottles onto the

Bottle Tray as shown in FIG. 8. The Tray is

designed for a 38 high Acetylene Tank with a

diameter of 8 1/2 and a 48 high Oxygen Tank

with a diameter of 7 1/2.

7. Install (99-0453) Bottle Restraint Assembly to

Flatbed Assembly by using the two 1/2-16 x

1-1/4 Lg. Flange Lock Hex. Hd. Cap Screws

removed in Step 1. Be cautious not to install

Bracket upside-down. The Bottle Restraint

Assembly should have the longest slot closer to

the front of the unit. Tighten the two screws

securely in the existing tapped holes in unit. See

Illustration on page 10, (Model No. 07269) Item

11. The Assembly is now complete.

SET-UP

NOTE: Refer to Torque Specifications on page

5 for all Fasteners.

5. If unit has an existing (99-0463) Guard Brace

Strap installed for the Fuel Tank Guard, remove

nut from screw that mounts the Guard Brace

Strap to the Workman®unit. Slide the end hole

of (99-0480) Tray Support Strap onto the 3/8-

16 x 1 Lg. Flange Lock Hex. Hd. Cap Screw

Fig. 8

1

2

3

1. Oxygen and Acetylene Bottles

2. Bottle Restraint plate 3. Optional Bottle Tray

FIG. 7

1

1. Existing Inserts

1647

1

10

# Part No. Description Qty# Part No. Description Qty

1 99-0433 Flatbed Assembly 1

2 99-9719 Block - Wear 4

3 3250-45 Screw - Plain Hd. 1/4 8

4 32128-33 Nut - Flange Lock 1/4 8

5 99-0459 Tank Guard Assembly 1

6 99-0463 Strap - Guard Brace 1

7 99-0480 Strap - Tray Support 1

8 99-0476 Bottle Tray Assembly 1

9 3234-11 Screw - Cap HH 3/8 Flng Lck 10

10 32128-43 Nut - Flange Lock 3/8 5

11 99-0453 Bottle Restraint Assembly 1

12 99-0455 Cover Plate Assembly 1

13 92-2667 Bracket - Attachment Mount 2

14 3234-32 Screw - Cap HH 1/2 Flng Lck 4

15 325-17 Screw - Cap HH 1/2 4

16 32128-49 Nut - Flange Lock 1/2 6

17 3234-4 Screw - Cap HH 1/4 1

18 32128-33 Nut - Flange Lock 1/4 1

19 92-1233 Pin - Clevis 2

20 92-1298 Pin - Lynch 4

21 99-0451 Plate - Rear Pin 4

22 99-0488 Decal - Bed Warning 4

23 99-0547 Foam Tape 1/4 x 1 1/2 x 7 4

24 99-0739 Strap Cover 8

25 3234-5 Screw- Cap HH 5/16 Flng Lck 16

26 32128-44 Nut - Flange Lock 5/16 16

# Part No. Description Qty

11

# Part No. Description Qty

Item must be serviced by a Mitsubishi Authorized Toro Dealer/Distributor.

1 99-0465 Plate - Skid 1

2 99-0466 Adjustment Plate Assembly 1

3 99-0468 Bumper Assembly 1

4 92-2700 Bracket - Hitch Arm 2

5 92-2752 U Bolt 2

6 3234-11 Screw - Cap HH 3/8 Flng Lck 9

7 323-8 Screw - Cap HH 3/8 2

8 3234-9 Screw - Cap HH 3/8 2

9 32128-43 Nut - Flange Lock 3/8 16

10 325-6 Screw - Cap HH 1/2 2

11 32128-49 Nut - Flange Lock 1/2 2

12 99-0473 Cap - Bumper 2

13 92-2724 Decal - Hitch Rating 1

14 99-0475 Bolt - Governor 1

Replaces Governor Torque

Spring Set to protect against

magnetic interference in

industrial applications.

12

®

This manual suits for next models

2

Other Toro Industrial Equipment manuals

Toro

Toro 04246 User manual

Toro

Toro MB TX 2500 User manual

Toro

Toro OSMAC G3 Satellite User manual

Toro

Toro 110-5076 User manual

Toro

Toro MB TX 2500 User manual

Toro

Toro Greensmaster eFlex 1021 User manual

Toro

Toro MH-400SH2 User manual

Toro

Toro Groundsmaster 3320 User manual

Toro

Toro Workman Topdresser 1800 User manual