PINO Medium User manual

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 1

Wing span [mm]:

2500

Wing area [dm2]:

44

Aspect ratio: 14

Take-off weight [g]:

from 1400-2100g

Wing loading: 32-48g/dm“

Airfoil:

VS2/ VS3/ VS4/ VS5/ VS6

Modern F3b-F3f airfoils

BUILDING INSTRUCTION

Allround fun glider PINO

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 2

CONTENTS

DATA

1. Kit – contents

2. What else do you need?

3. Electronic equipment

ASSEMBLING THE MODEL

4. Wing

4.1 Controlling flaps and ailerons

5. Fuselage

5.1 Servos

5.2 Contacts for flaps and ailerons

5.3 Accumulators

5.4 Connection of rudder

5.5 Canopy

5.6 Hook for winchstart

6. Ballast

7. Settings for the first flight

OTHER

8. Check list before starting

9. Notes for use

3

3

3

4

4

8

8

8

9

10

10

10

11

12

15

15

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 3

DAT

A

1.

Kit

–

contents

Fuselage + canopy

Wing

Elevator

Lever for controlling rudder, 1 pc.

Lever for controlling ailerons, 2 pc.

Lever for controlling flaps, 2 pc.

Steel wire 1,2mm for rudder, 1 pc.

M2,5 screw rod for controlling ailerons, 4 pc.

9x lever connectors M2,5

M4 metal screws for fixing wing, 4 pc.

M4 nylon screws for fixing wing, 4 pc.

Spring-loaded contacts 2 pairs.

Building instruction (for download from our website)

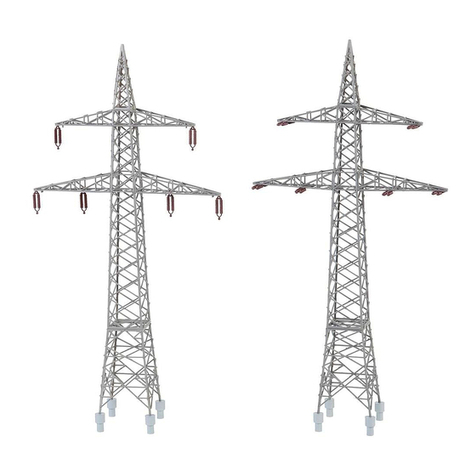

Connetors / allast:

Segler / Glider Elektro

Normal Slope

Medium

x Kohlesta /

aron rod

x Stahl lang / steel long

x Stahl kurz / steel short

x Kohlesta /

aron rod

x Stahl lang / steel long

x Stahl kurz / steel short

Ultralight

2. What else do you need:

Epoxy-glue (for example UHU 300 endfest or Pattex Stabilith)

Super glue (runny)

Electrical equipment (On/Off-switch, cables, plug...)

Electronic equipment

Shrinking tube...

3.

Electronic equipment

Servo aileron and flaps: - KST DS 135 MG

Servo rudder and elevator:

- KST X08

Accumulators:

- Eneloop 2200mA/h

Receiver: - for 4 wing servos, rudder and elevator.

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 4

4

.

WING

4

.1

Controlling

flaps and

ailerons

Fixing the servos

First of all, prepare the surfaces which will be glued. Grind

them with a rough paper (about 80-40 grain size).

Then, set the servo to the

zero position

and

screw it to the

frame. The screwing is important, because if you screw the

servo after gluing it into the wing, tension will occur and the

surface of the wing will get wavy.

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 5

The

lever length

s:

Aileron: 8mm (first hole of

the smaller lever of the KST

servos.)

Flaps: 10mm (first hole of

the stronger lever of the KST

servos.)

The length is measured from

rotation center to hole center.

Flap servo:

Set the servo to its zero position and let the lever show a little

bit to the front. So you get more break deflection.

Aileron servo:

Let the lever in rectangular position.

Verify the

free movement

of all the

parts.

It will be necessary, that you

optimize the lever

connector as shown in the

pictures besides.

It has to be done in different

ways for the flaps and for the

ailerons.

Aileron servo

Flap servo

Prepare the parts for gluing

the control levers into the

wing. Grind all gluing

surfaces, the slot of the

control surfaces and the

levers themselves.

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 6

The

bolt

of the

lever

connector has sharp edges

that are bigger than the bolt

diameter. You should

remove these edges, before

you put the connector into

the lever. It is easy to clean

that bolt with nose pliers.

Grab the bolt with the nose

pliers and move the

connector up and down

about 3 times as shown in

the picture. Repeat this that

often until the connector is

able to move in the lever

hole without a lot of

friction.

Before you glue the lever into the control surface,

fix the

connector to the lever.

You can use

runny super glue

to fix the levers. This kind of

bonding will be strong enough for the forces occurring.

Cable mounting:

Mill a hole into the preformed space for the contacts. Make the

hole big enough, so that the contacts will not touch the

carbon.

Now,

slide the cables

through the hole.

Then solder the cable to the

contacts.

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 7

It is very important to

insulate all the contacts

that could touch the carbon.

We use “Plasti Dip” for such

purposes.

Make sure that the contact

fits easily into the free

space, which is provided for

the contact, without putting

any force on the soldered

areas.

Before you fix the contact

with a drop of runny super

glue, check if all the servos

work well.

Now you can stick the

seals over the gaps

.

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 8

5. FUSELAGE

5.

1

Servos

All necessary

holes

are

already pre-milled.

The holes for the servos are

especially dimensioned for

the KST X08 V3 . You just

have to screw in the servos

and connect them to the

pushrods.

Set the servos and the

controls (elevator and the

rudder) to the zero position

and connect them.

Th

e

lever lengths

are:

Elevator: 10mm (big KST

servo lever 2nd hole)

Rudder: 8mm (cross shaped

KST servo lever 2nd hole)

5.

2

Contacts for flaps and ailerons

Next, let’s finish the

aileron

and flap contacts for the

fuselage.

The cable length should be

about 32cm.

Pay attention that you solder

the contacts in the same way

as they are soldered in the

wings.

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 9

Then put a little bit

5 minute epoxy with cotton flocks

around

the contacts.

So you insulate and strengthen the soldered parts.

The rest of the contacts have

to be insulated extra

Before you fix the contacts to

the fuselage with a runny

super glue, make a test, if

everything is contacted

well.

5.

3

Accumulators

Pack the Eneloop cells

the

way it is shown in the picture.

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 10

That way there should be

space enough also for

bigger receivers.

5.

4

Connection of rudder

Fix the

lever in the control surface

and connect it to the

steel

pushrod.

Make a mark for the zero position of the elevator on the

rudder.

5.

5

Canopy

We use a very simple solution to mount the canopy.

Just glue the carbon stick into the canopy. Note that the gluing

spot is only in the middle of stick and canopy, so you can

thread the stick into the fuselage while the canopy remains on

the outer side.

5.

6

Hook for

winchstart

There is a

plywood part in the skin of the fuselage

, so that

you can drill holes into the fuselage to position your hook.

We recommend to start with a position of about 2cm in front of

the CG.

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 11

6. BALLAST

In the kit included are:

- 1x carbon rod

- 1x steel rod

- 2x short steel rods

You can use these rods as follows:

- 1x carbon rod for weak conditions in the front hole.

Adjust the CG of the plane with this rod inside.

-

1x carbon + 1x steel

rod

for

stronger conditions

-

1x carbon, 1x steel rod + 2x short steel

for

even stronger

conditions.

-

For extra strong conditions

you could put into a

40cm long

steel rod and two 20cm steel rods behind. That ballast

weights 700g.

When you fly with this setting, you have to take care that you

don`t overload the wing structure. So use the elevator

softly, when you fly with that much ballast. Remember also

that the landings have to be much softer with such an

additional weight.

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 12

7

.

SETTINGS FOR FIRST FLIGHT

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 13

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 14

www.modellmarkt24.chwww.modellmarkt24.ch

PINO Building Instruction October 2015

www.pcm.at 15

OTHER

12.

Check list before starting

:

1.

Check

centre of gravity

2. Check control surfaces:

Do control surfaces move in the correct direction?

Check the greatest swings

3. Check reception

4. Check control surfaces before each flight.

Do all control surfaces still move correctly?

Is there enough power in the accumulator?

Are the brakes retracted?

You can save the retraction of the brakes in your start

setting. By this, you can never start with extended

brakes.

5. Gentle launch in the flat. If there are some wrong settings,

you will realize it during a gentle throw in the flat.

13.

Notes for the use

To avoid heating of the carbon surface, models with carbon

wings should not lie in the sun.

During flight heating by the sun is no problem, as the model is

cooled by the wind. On ground the glider should be kept

inside protective bags or in the shade.

After every ungentle landing, you must check your model for

possible damage, such as:

- Is the radio board still glued thoroughly?

- Did the leading edge of the wing burst open?

- Did rudder or elevator get damaged?

Table of contents

Popular Toy manuals by other brands

The Wings Maker

The Wings Maker Handyman EP instruction manual

Mega Construx

Mega Construx Futurama Kubros Fry manual

Horizon Hobby

Horizon Hobby Hangar 9 Ki-43 Oscar 60cc instruction manual

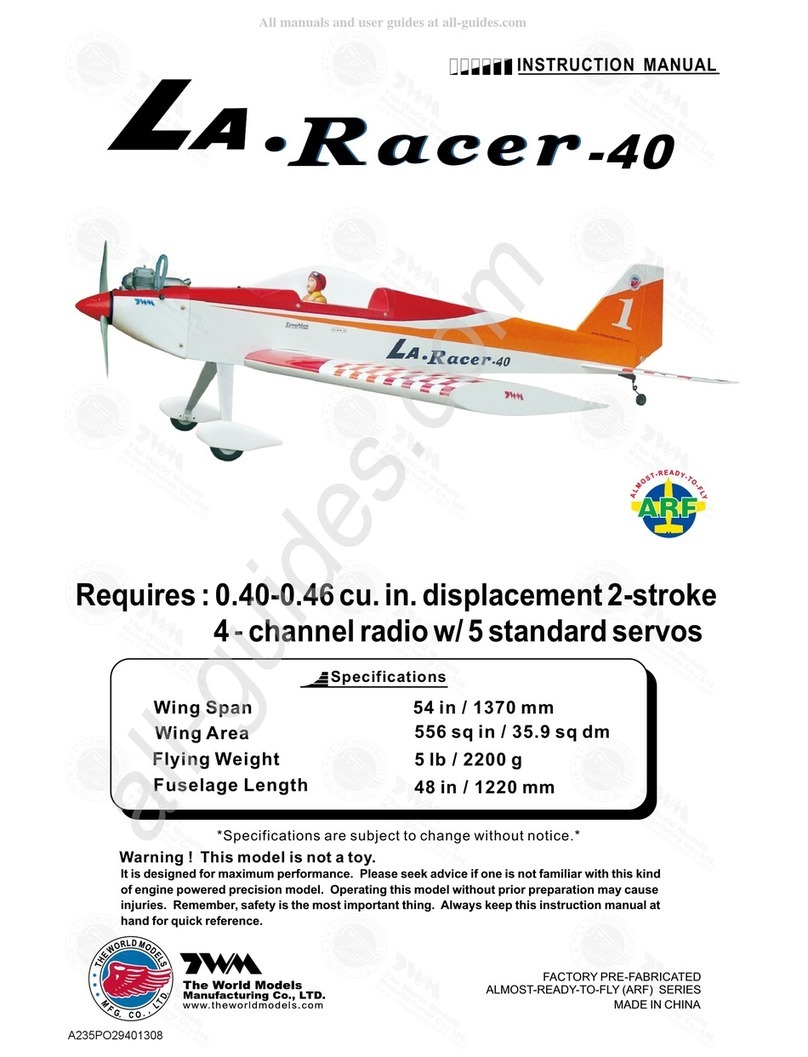

The World Models Manufacturing

The World Models Manufacturing LA RACER-40 instruction manual

LGB

LGB 23500 instruction manual

LEGO

LEGO Ninjago 70733 instructions