13/124

13 /20

EN

This manual is the property of PIUSI S.p.A. Any reproduction, even partial, is forbidden.

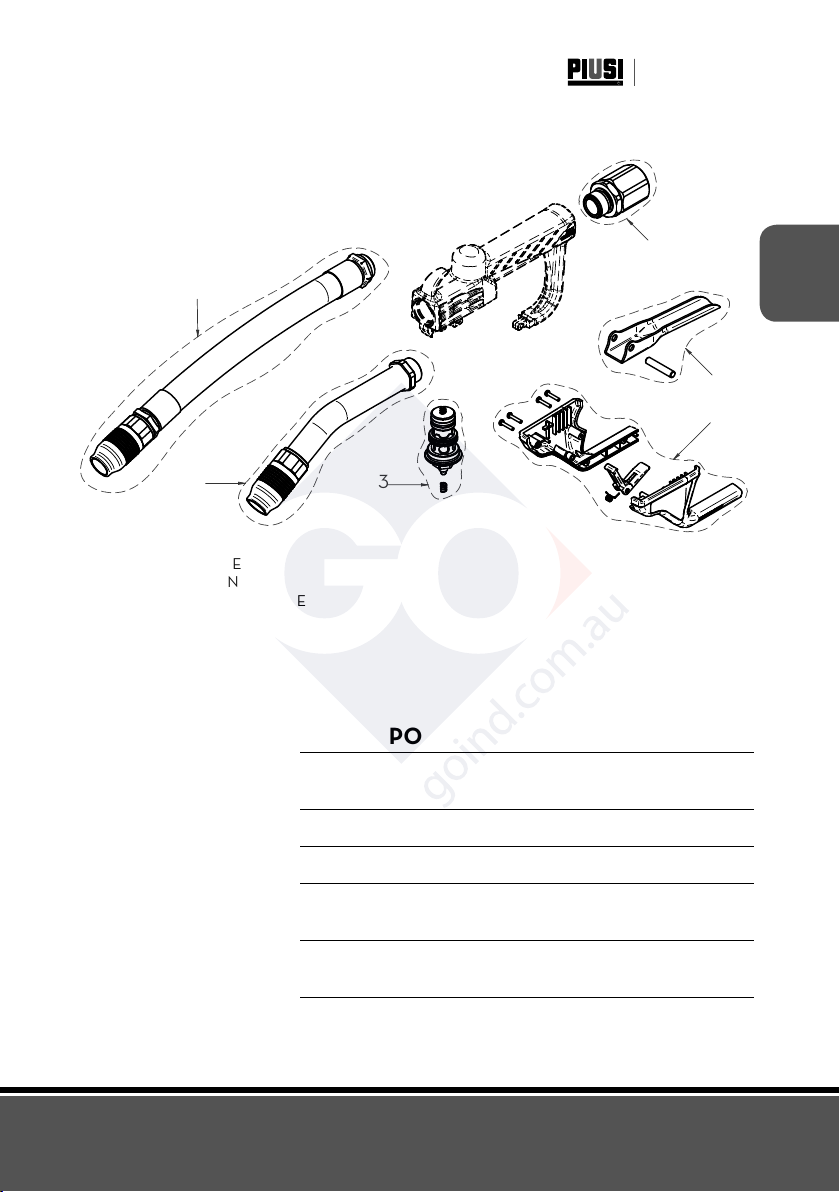

translated from italian PISTOL-ONE

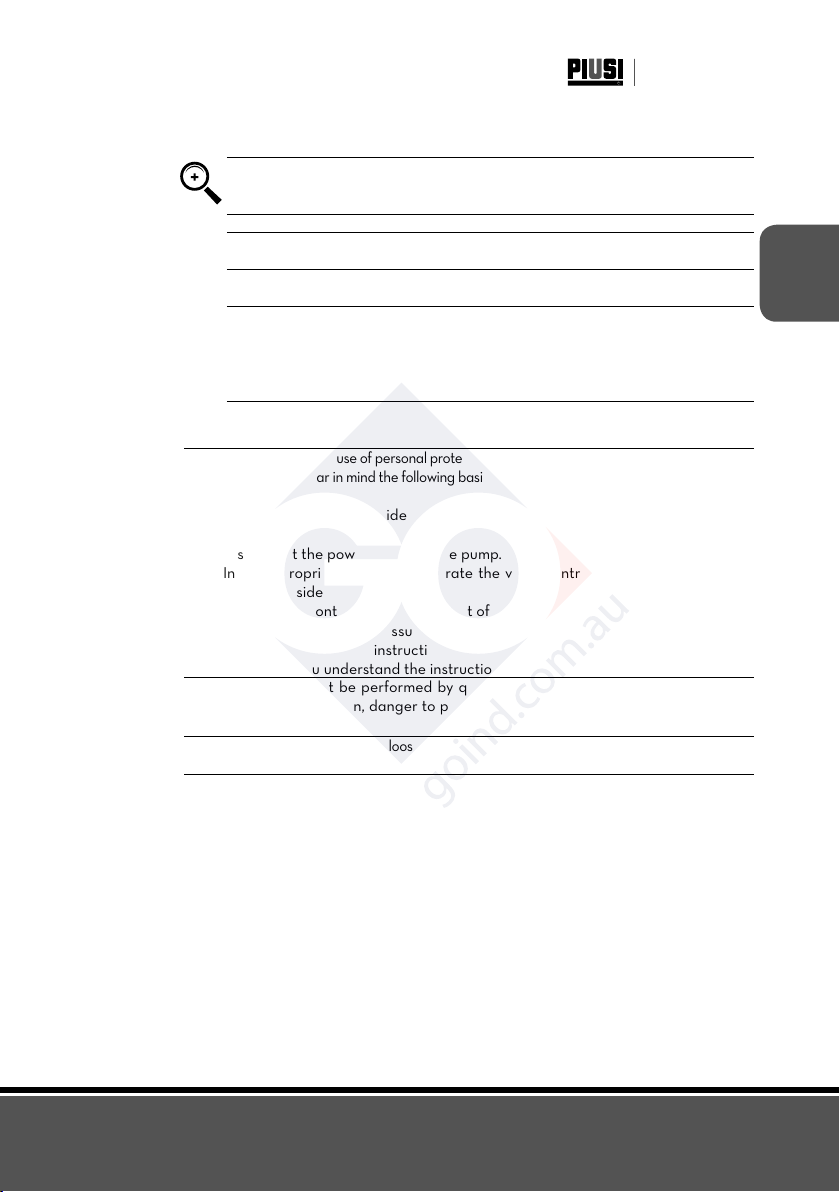

6 USE AND VERIFICATIONS

NOTE perform the following procedures to allow the pump to begin the cycle.

Adjust the amount of air to the pump with pressure regulator.

If the valve leaks at any time, refer to the troubleshooting table.

1Point the gun into a suitable container to hold the dispensed fluid.

2Allow the pump to prime fluid to the control valve.

- The control valve must not show leaks or dispense fluid.

3Operate the gun lever assembly several times.

- The fluid should flow once the air has been eliminated.

With the lever in the released position, no fluid should come out of the spout.

To lock the handle, press the lever, press the stop button and release the lever.

To release the latch, press and release the lever.

If fluid leaks, refer to the troubleshooting table.

The anti-drip valve opens automatically during delivery.

7 MAINTENANCE

Safety

instructions

During maintenance, the use of personal protective equipment (PPE) is compulsory.

In any case always bear in mind the following basic recommendations for a good functioning of

the product

• Release all pressure inside the system before carrying out any maintenance

procedure.

• Disconnect the power line from the pump.

• In an appropriate container, operate the valve control to release the residual

pressure inside the system.

• Never aim a control valve at any part of the body or another person.

• Accidental release of pressure and / or material can cause personal injury.

• Read each step of the instructions carefully.

• Make sure you understand the instructions correctly before proceeding.

Authorised

maintenance

personnel

All maintenance must be performed by qualified personnel. Tampering can lead to

performance degradation, danger to persons and/or property and may result in the

warranty being voided.

ONCE A

WEEK:

Check that the pipe joints are not loose, to avoid any leaks.