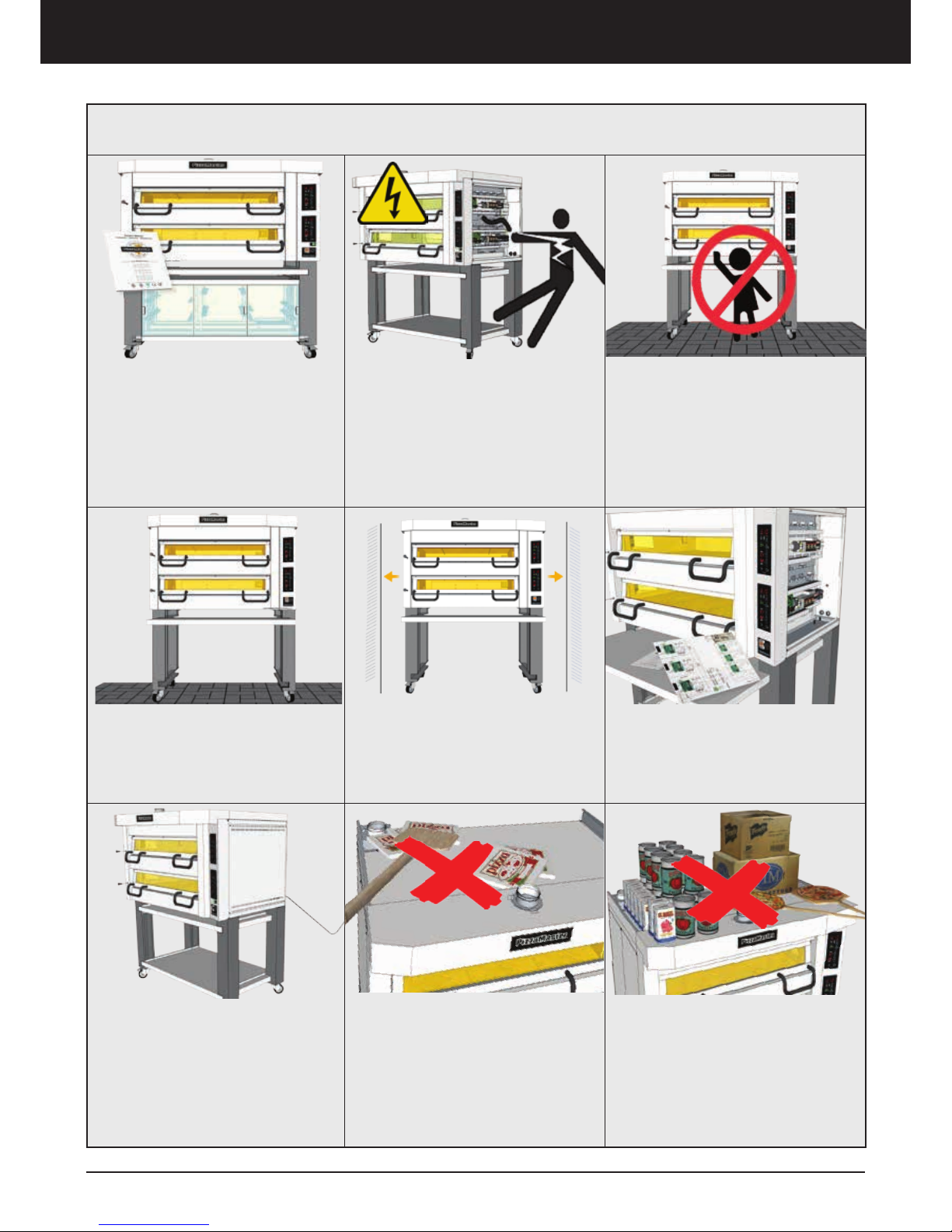

For ventilation reasons, position

the oven leaving 50mm (2”) bet-

ween the oven and any adjacent

wall

If possible, position the oven so that

its right-hand side can be accessed

easily in order to remove the right-

hand panel. This gives easy access

to the back of the control panel and

facilitates servicing of the oven.

The oven is normally installed on

the legs supplied with it. It is also

important for the floor to be flat,

so that the oven is both horizontal

and stable.

Safety Precautions and Warnings

This appliances is not intended for

use by persons (including children)

with reduced physical, sensory or

mental capabilities, or lack of ex-

perience and knowledge, unless

they have been given supervisory

or instruction concerning use of the

appliance by a person responsible

for their safety.

High Risk of Electrocution!

Disconnect appliance from power

supply before opening.

To reduce the risk of electric shock,

DO NOT remove or open electrical

cover. Refer servicing to qualified

personnel.

To ensure safe operation, read

the following manual that contains

safety precautions and warnings

for your own safety

Safety and Warnings

The appliance must be installed with an

adequate restraining to limit the move-

ment of the appliance without transmit-

ting stress to the electrical conduit.The

restraining must be fastened in one of

the supports leg or spacers.

The appliance must be installed with a

flexible conduit.

DO NOT place any object blocking

the ventilation. this affects the

baking, oven performance and may

cause fire

The top of the oven is not consid-

ered as a food storage or as an food

preparation area.