Thank you for purchasing our product!

The Voodoo Mustang is a high-performance aircraft designed for RC pilots with intermediate to

advanced skill levels. Read carefully through this manual to ensure that the assembly process is

completed properly, resulting in a safe maiden flight. We have flight tested this model

extensively. We have made some modifications to this ARF kit, delivering a product that will

move from your workbench to the flying field in as fast as possible. We want you to be out

enjoying your product without being slowed down by the assembly process. For more tips,

tricks, and information, visit us at www.RCGroups.com.

Build Safely

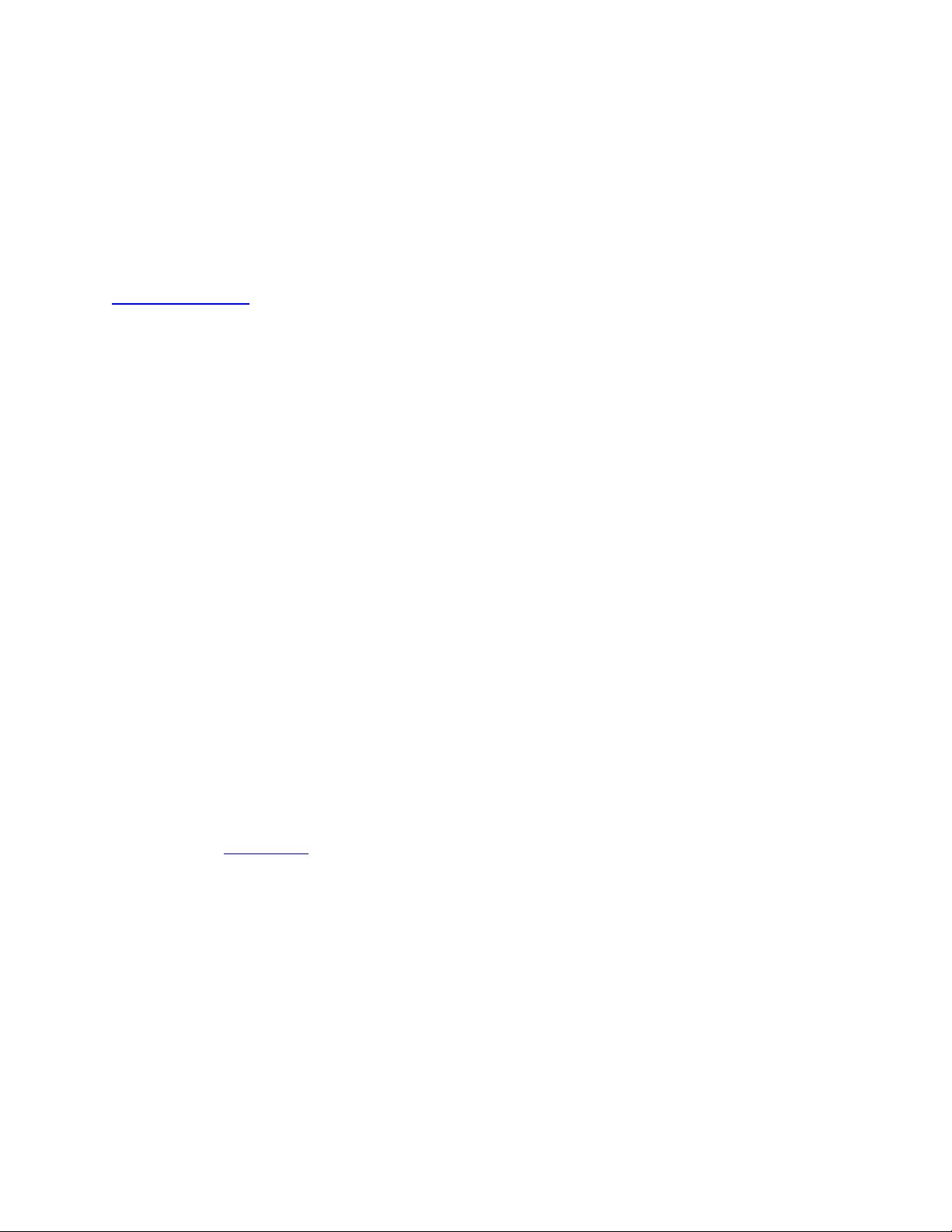

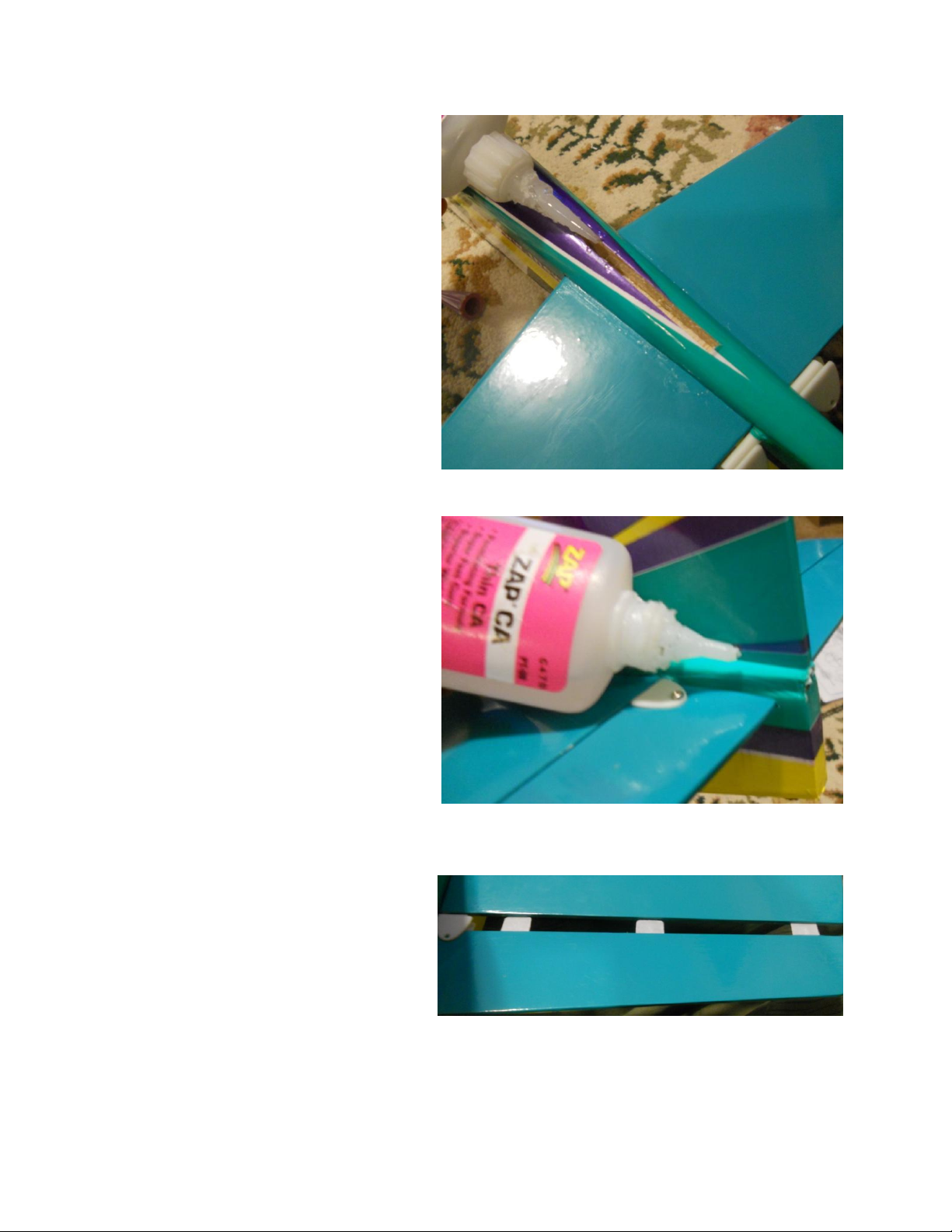

The build process for this ARF kit will require the use of hobby adhesives and sharp knives.

Please exercise caution by working in a well-ventilated area with protective gloves when

working with adhesives such a CA glue or Epoxy. Be sure that all hobby related tools and

equipment are stored out of reach of children and that you have a first-aid kit readily available.

Take your time through the assembly process and read through the manual fully before you

begin. If any of the steps seem unclear, double-check this manual or send us an e-mail if you

have any further questions. Careful preparation is the key to a successful first flight. Please do

not rush through this process or skip important steps.

Fly Safely

We always advocate proper flight safety when operating any model aircraft. Always have

current AMA membership before operating any model aircraft. The Academy of Model

Aeronautics is the governing body for model aviation in the United States and membership is

required at any AMA chartered flying club. Membership is a real benefit as it provides members

with liability insurance as long as the AMA safety code is followed by the pilot. For more

information about AMA membership, visit www.modelaircraft.org.

We advocate safe operation of this aircraft because it is extremely fast and maneuverable.

This model is NOT A TOY, and should be operated only by experienced pilots under careful

supervision. Fly only at locations that are AMA sanctioned flying sites. Avoid flying near power

lines, trees, over streets, vehicles, people, or near full-scale aircraft. If your plane becomes

caught in a tree or power lines, DO NOT attempt to retrieve it yourself. Contact your local

authorities for assistance. Power lines are extremely dangerous, and falls from trees or ladders

can result in serious injury or death. When testing any electrical components of the aircraft

remove the propeller from the motor before you begin. Never operate a brushless motor

indoors with the propeller attached. Do not fly too close to yourself and spectators. Propellers

are very sharp and dangerous. Check your radio equipment and make sure that it is functioning

properly. Make sure to follow all of your manufacturer’s guidelines for your radio system.