2

A DVD is available upon request that illustrates

many stages in this book. The film shows a project

from start to finish as an informative guide which

supplements this book. For detailed instructions

please primarily use this book. You are advised to

watch the entire DVD and read this whole book

before starting your project.

In the event of any problems please contact your

dealer immediately. Warranty claims will not be

entertained if there is delay in reporting a problem or

these instructions have not been followed.

A copy of the installation DVD is also available at

http://goo.gl/1f7y8w

Introduction

• Do not store the wood in direct sunlight or under a

black cover as this will cause distortion which will

make installation extremely difficult.

• Assemble the structure as soon as possible after

receipt.

• Assemble the structure in one go, preferably in the

morning while the temperature is cool.

• If the pool must be stored then use a cool well-

ventilated place, sheltered from sun and rain. If

possible keep the pool in its original packaging.

• Components that are damaged, cracked or

distorted due to bad storage and/or handling on

site are not covered by warranty.

In the pre-assembly period the wood is sensitive to

variations in temperature and humidity. It is

therefore necessary that you take the following

precautions immediately after delivery.

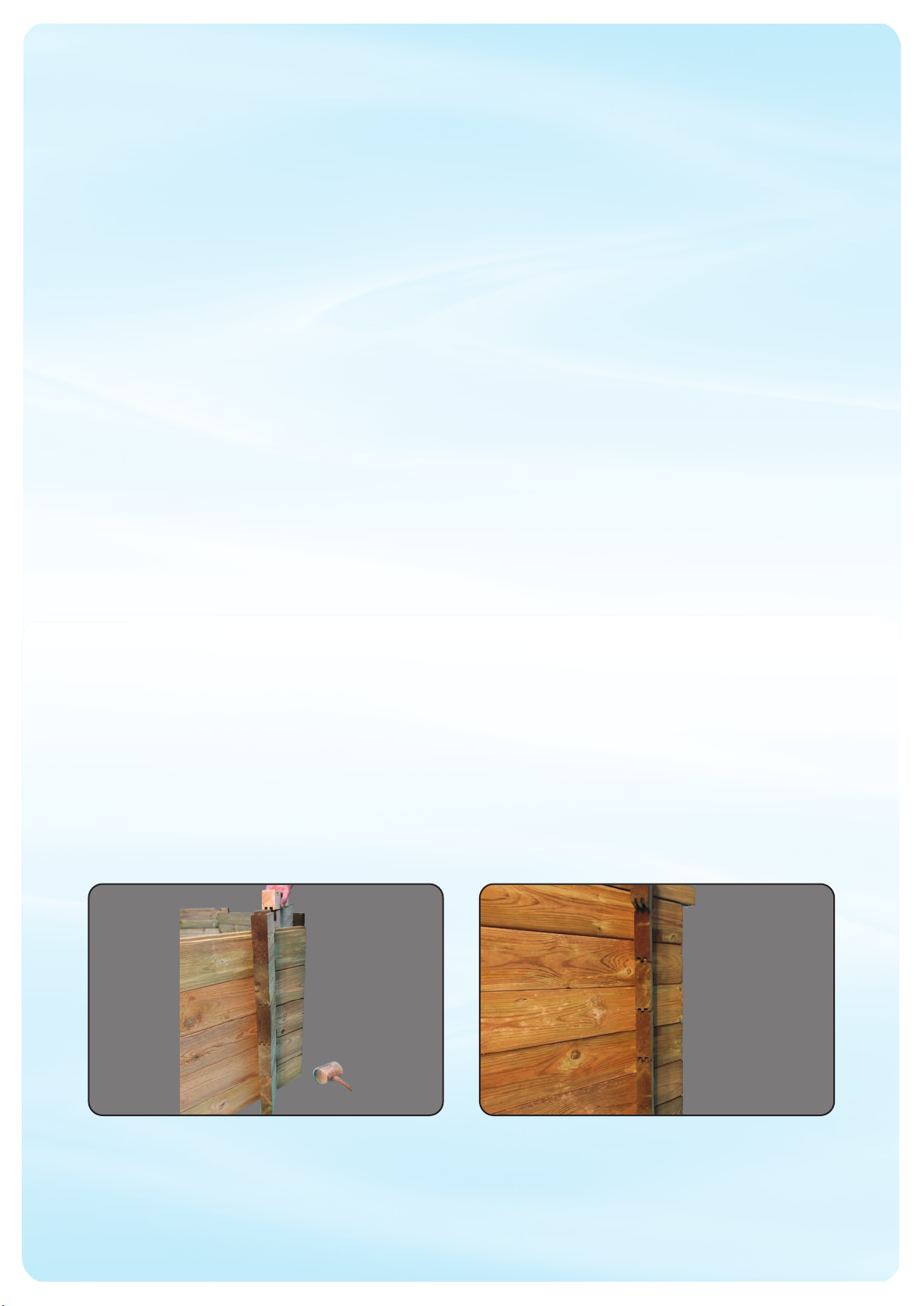

Wood is a living material and once cut the

appearance of cracks, slight movements or

changes in colour are normal and the planks

(except in extreme circumstances) do not need

replacing. The planks will have been recently

treated and may be delivered to you still moist. In

case of a rapid change in temperature; these planks

can dry very quickly and lose 1 or 2mm of height.

This might give you the impression that they are

lifting up while they are actually shrinking.

Recommendations for Storage after Delivery

• Unless your filtration kit (filter, pump and any

optional heating) is housed within a secure

waterproof enclosure, it should be placed at least

2m from the shell, you may need to purchase extra

pipe and fittings for this.

• It is important to ensure the electricity supply for

the pump or any other electrical item has 30mA

RCD protection and conforms to present electrical

regulations.

• Never leave children unattended around the pool

when completed or at any stage of construction.

• The pool is designed for domestic use. Running

along the top rail, diving or jumping into the water

from the edge must not be allowed under any

circumstances. The pool is not suitable for the

addition of diving boards.

General Safety Precautions

Both the equipment box and the pallet of wooden

planks contain a packing list detailing the contents.

As you unpack your pool check that you have all

parts required and that their condition is satisfactory.

Contact your dealer immediately if you are in any

doubt or believe parts may be missing/damaged.

it Contents

For octagonal pool models please ignore information given for metal bracing.

This is not relevant to the model you have purchased.

Important Note

There are no specialist tools required but in addition

to regular hand tools the following will be useful.

• Heavy mallets for assembling walls.

• Large spirit level and set square.

• Quality battery drill with screw driver bits, drill bits

and counter sink.

• Wet & dry type vacuum cleaner for fitting the liner

• Clamps for holding components.

• Large mitre block with 90 & 22½ degree slots for

cutting pipes and liner lock.

• Large scissors for cutting underlay felt.

Required Tools