*About my favorite soldering technique:

After many years of soldering electronic circuits I have found that I prefer to solder

most of the through hole components from the side where the components are

(when possible, especially resistors) with a sharp conical tip.

In this method I can see the component at the moment of soldering, I can work on

flat surface without helping hands and I succeed to get beautiful soldering points that

works 100% of the time.

If you have already adopted a preferred soldering method use it, you are of course

welcome to watch my method in the attached videos and try it.

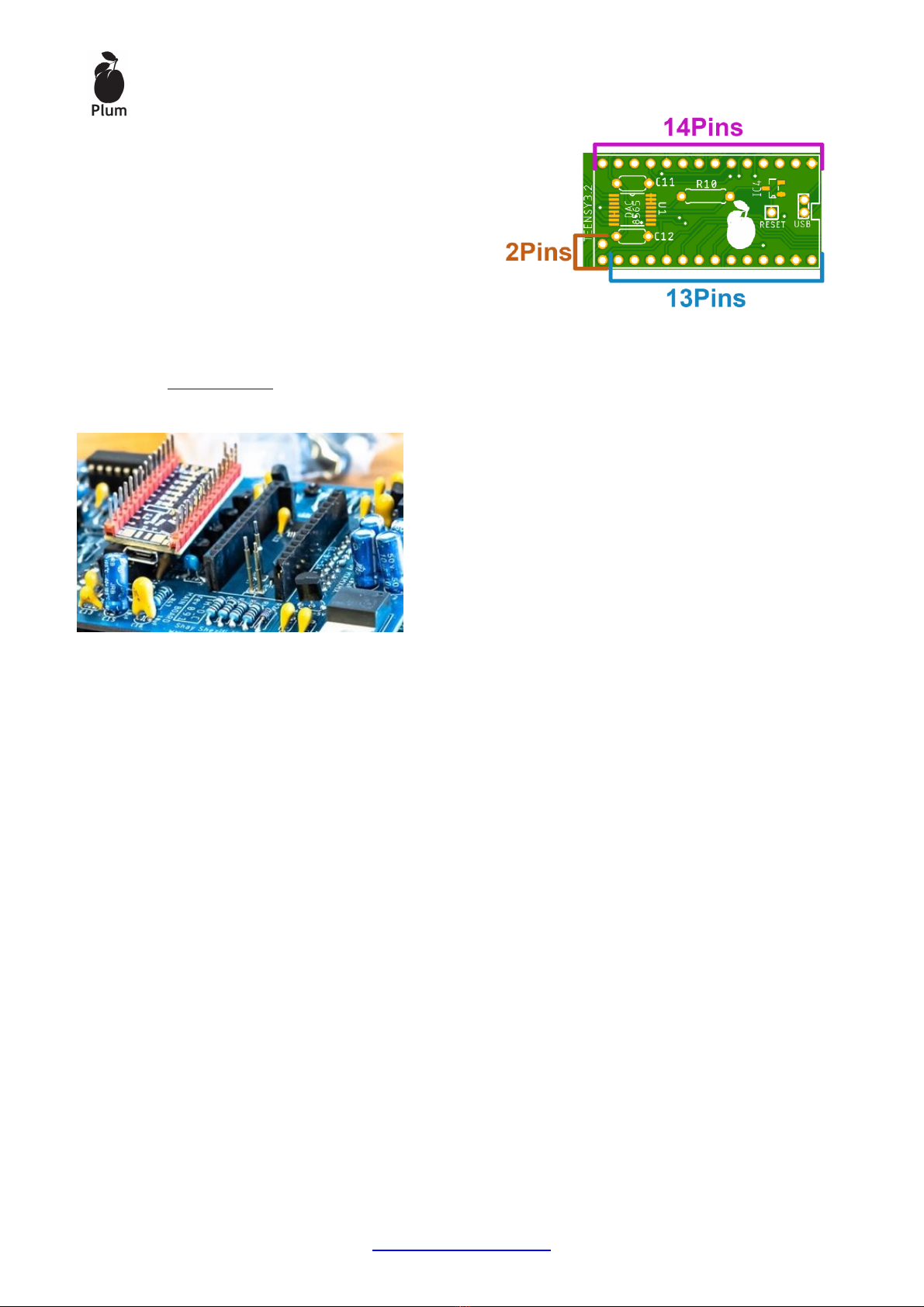

STEP 1 –MAIN BOARD ASSEMBLING:

The most efficient way is to assemble the components according to their height on

the board, so it is advisable to start with the lowest components and move to the

higher components.

Solder components at this order:

Watch Video

1. Resistors and Inductor:

Inside the components bag you will find 3 bags with all the resistors needed

for the Main board:

Bag 1: 100R, 100K, 10K and 10uH Inductor

Bag 2: 220R, 1K, 2K

Bag 3: 24K, 33K, 75K

*How to identify resistor value?

The resistors inside the kit are arranged in strips, you just have to count the number

of resistors in each strip and cross with the number written on the bag label to know

what the value is. But it's always a good idea to make sure the value is right, for that

you can use your DMM to measure the resistors in each strip or use the color coding

of the resistors, you can use this color code calculator.

2. Diodes –Polarity is mandatory, the line on the diode should match with the

line that printed on board

1N5819 to D1, D2

3. IC’s sockets for IC6, IC7, IC8, IC9, IC10

The orientations of the sockets are not really matter but IC's

orientation is mandatory!

I’ll recommend to solder the sockets at the same orientation

that printed on the board In order to avoid confusion when

assembling the IC’s, In general –in both OCP boards

horizontal IC's are facing left and verticals IC's are facing up.

do not connect the IC’s to the sockets at this stage.

* Paper masking tape can help you to hold the sockets in their

places before you flip the board to solder them on the bottom

side.