Installation Procedure

(For installation firms –can be performed by an authorised person only)

1. Put a mounting sheet next to the wall and mark the size of the sucking opening.

2. Sink the opening.

3. Seat the sucking piping descending into the heater (maximum gradient can be 5mm), render

internal wall or fix it in the wall with an alternative insert.

4. Put the mounting sheet on, align it horizontally and mark the first opening for the anchor

screw. Drill an opening of 6. Put a combined screw into to fix the sheet. Mark another opening

and repeat the procedure. Having drilled all four openings (always 6) take the combined

screws out and remove the mounting sheet. Enlarge the openings to 12. Insert enclosed

fasteners. Screw the anchor combined screws into the fasteners. Use the both enclosed nuts to

screw the screws. Put them onto the metric part of the screw thread and lock them contrary.

5. Plug the mounting sheet onto the sucking piping (already fixed in the wall) and combine

screws with one left nut. Align the sheet to have it parallel with the wall. The sheet has not to

touch the wall. Distance between the wall and the sheet should be 25 –30 mm. The distance

is to be setas a stop end on the screw by a nut.

6. Mark the length of the sucking piping. Please note that the tube has to exceed the

mounting sheet by about 1 mm even after being shortened. Remove the mounting sheet.

Detach the not required part of the sucking piping.

7. Put the mounting sheet against the stop ends (the nuts –if you have followed the instructions

the correct position of the sheet against the wall and the sucking piping is still set by the nuts).

Use the second nut to tighten the mounting sheet. The overlapping part of the sucking piping

(1mm –§ 6) is to be bent using the metal part of a screwdriver along the whole circumference of

the tube in the direction out of the centre. This way the piping is fixed in the mounting sheet, and

its unfavourable loosening is avoided.

8. Unscrew the upper and lower (placed on the mounting sheet) holders of the exchanger’s

body. Insert the exchanger’s body into the sheet and tighten it by the holders.

9. Insert the exhaust piping. If needed shorten its length to exceed the sucking piping by 25-30

mm. It is important to mark (and then to shorten) the length having the tube sat on the

whole exhaust’s throat in the exchanger’s chamber and also kept the overlapping of the

exhaust over the sucking piping (see the enclosed drawing). Fix its position with a longer

screw placed in the sucking piping flange.

10. Put the basket on and fix it with screws.

11. Prepare a service line for the heater (DN 15). Connect the heater with a hose (a part of

delivery) with a coupling of the ball valve (DN 15).

12. Put the heater’s cover on.

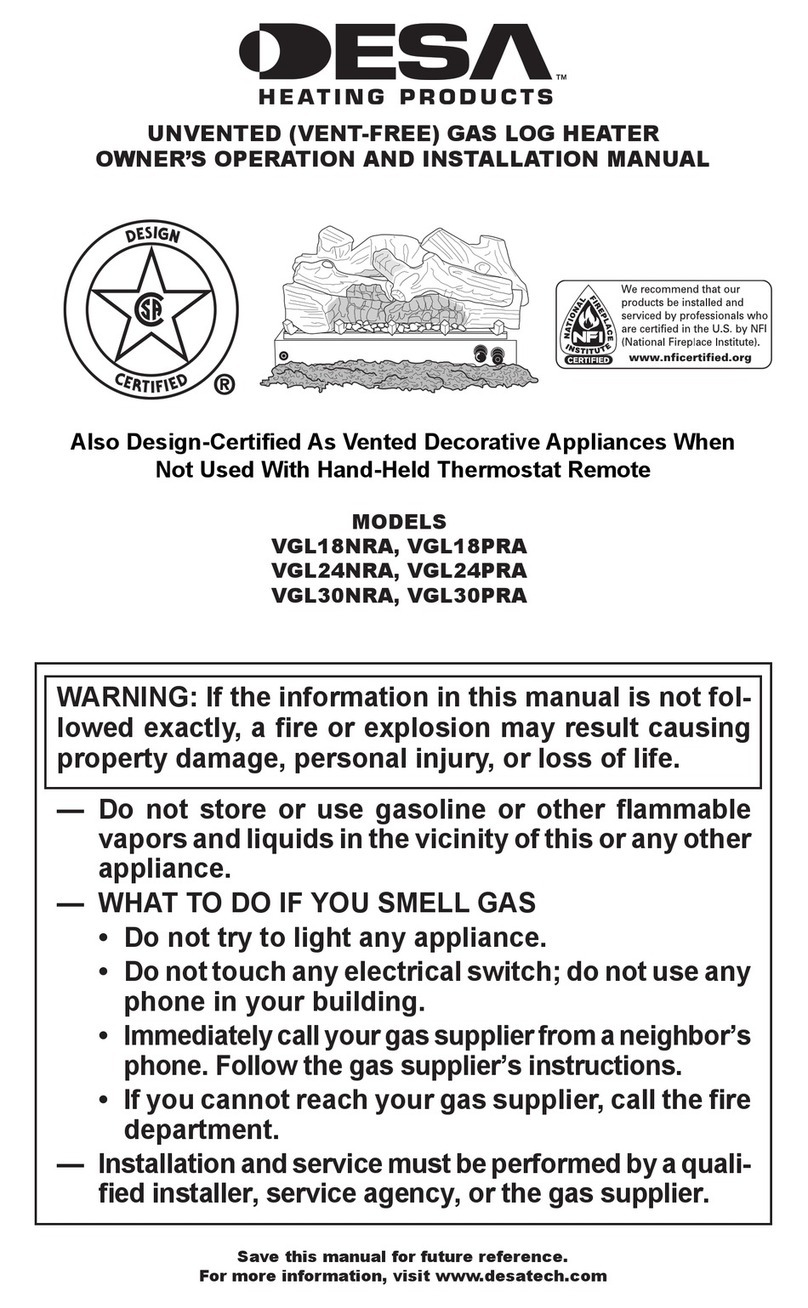

The heaters of the chimney type B has to have an emission draught interrupter installed –

see the drawing in the enclosure for the way of fixing of the heater.

Starting of Operation

(For service technicians - read carefully)

Check whether the main shut-off valve is open before starting of operation.

Follow these steps to switch the heater on:

1. Check whether the heater is installed correctlly –it has not be installed next to the wall,

i.e. the mounting sheet should be ca 25-30 mm distanced from the wall (not valid for the

chimney version)! Please take care for correct embedding of the emission piping. The

exhaust pipe is to be fixed to the sucking piping by a screw, to overlap it min. by 25mm, to

be fast put on the heater’s exhaust throat (see dimensional and location drawing in the

enclosure).

2. Check pressure on the small burner’s jet; adjust is with the adjusting screw to have the

burning flame height of ca 30mm. Arrange also immersing of the thermel into the flame (ca

3mm).