3

Safety Instructions

1. KNOW YOUR POWER TOOL

Read the owner's manual carefully. Learn its

applications and limitations as well as the potential

hazards specific to this tool.

2. THE OPERATOR AND ALL OTHER

PERSONNEL MUST WEAR PROPER EYE AND

EAR PROTECTION IN THE WORKAREA.

Wear safety goggles at all times. (Must comply with

ANSI Z87.1). Everyday eyeglasses have impact

resistant lenses only. They are NOT safety glasses.

Also, wear ear protectors (plugs or muffs) during

extended periods of operation

3. KEEP WORKAREA CLEAN

Cluttered areas and benches invite accidents. Floor

must not be slippery due to sawdust.

4. KEEP CHILDREN AWAY

All visitors should be kept a safe distance fromwork

area.

5. WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches) that could get caught in

moving parts. Wear non-slip footwear. Wear

protective hair covering to contain long hair. Roll

long sleeves above the elbow.

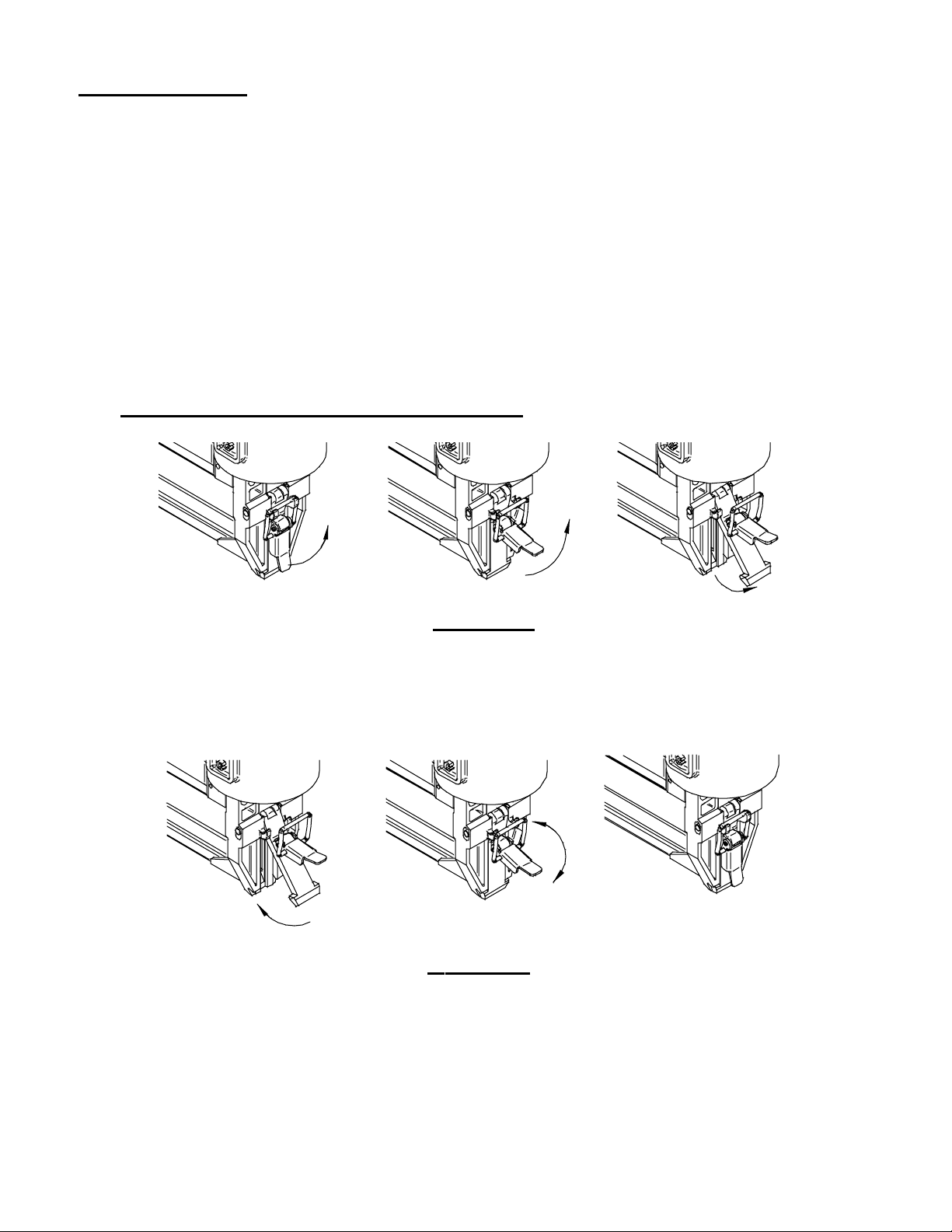

6. SECURE WORK

Be sure the tongue and groove of the flooring strips

are properly interlocked and secured in place before

nailing.

7. STAY ALERT

Watch what you are doing. Use common sense. Do

not operate tool when you are tired or while under the

influence of medication, alcohol or drugs.

8. ALWAYS INSPECT TOOL BEFORE

OPERATING.

Tool must be inspected prior to use to insure proper

use of power supply. Tool must be inspected to insure

proper working order. An improperly functioning tool

must not be used

9. KEEP HANDS, FEET AND OTHER BODY

PARTS AWAY FROM NAIL EJECTION AREA.

Serious injury could occur if body parts are not kept

away fromnail ejection area.

10. ALWAYS ASSUME THE TOOL CONTAINS

FASTENERS.

Do not activate the tool unless the tool is placed firmly

against the work piece.

11. NO HORSEPLAY.

Do not point the tool toward yourself or anyone

whether it contains fasteners or not.

12. NEVER TRANSPORT TOOL WHILE

DEPRESSING THE TRIGGER.

13. DISCONNECT TOOL FROM AIR SUPPLY

WHEN:

Moving the tool to a new location, performing any

maintenance or repair, clearing a jamor tool is

unattended.

14. NEVER SERVICE WHILE ATTACHED TO AIR

SUPPLY.

Always disconnect the tool fromthe power source

when servicing, or replacing parts.

15. DO NOT USE TOOL IF OPERATING

CONTROLS ARE INOPERABLE.

Do not remove, tamper with, or otherwise cause the

tool operating controls or safety controls to become

inoperable.

16. DO NOT OPERATE TOOL IFSAFETY

FEATURES NOT WORKING PROPERLY.

Disconnect tool frompower source if safety trigger or

operating controls are not working properly.

17. USE ONLYPORTA-NAIL FASTENERS.

Only use fasteners recommended by the manufacturer.

Use of other fasteners may cause serious injury,

jamming of tool or improper operation.

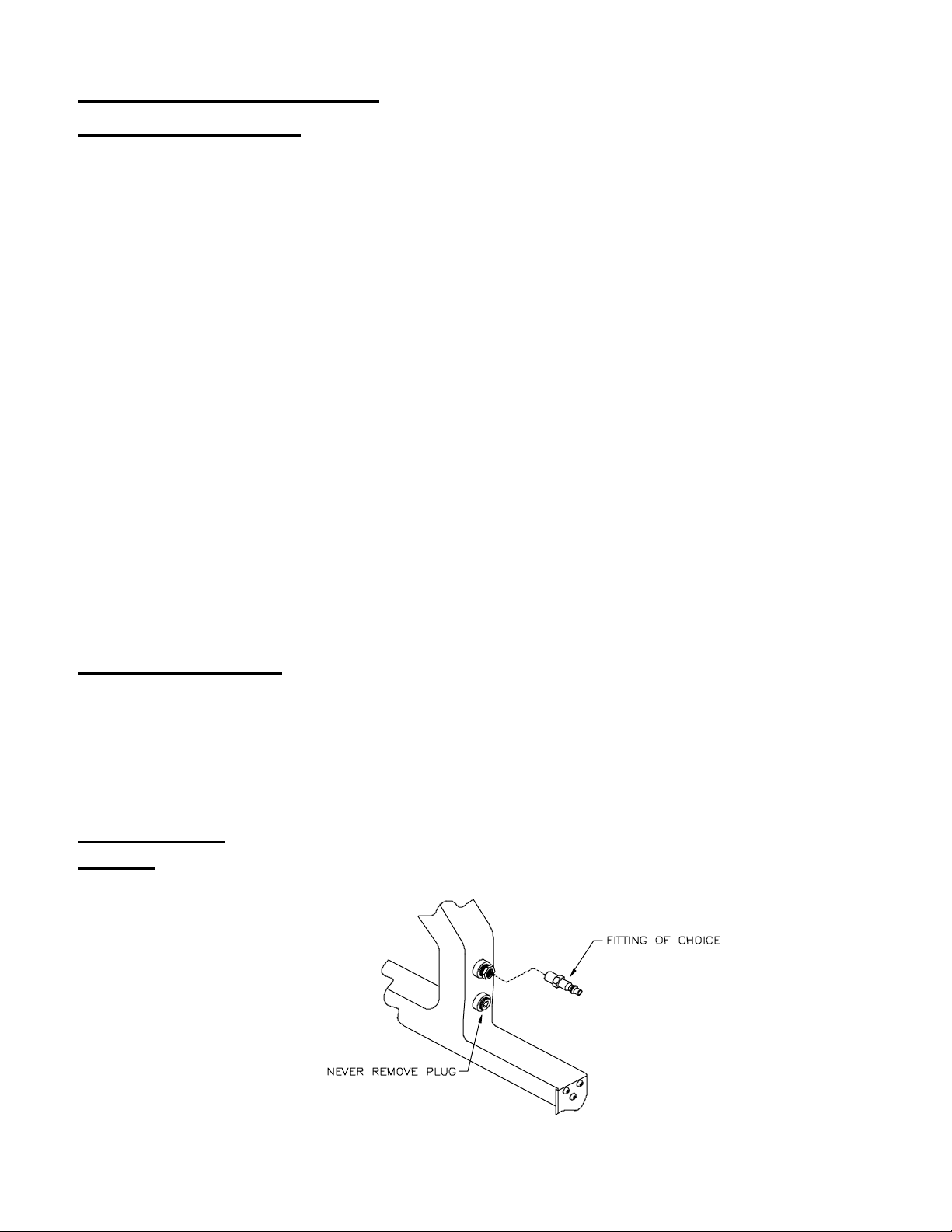

18. USE ONLYPRESSURE-REGULATED POWER

SOURCE.

Use only a pressure regulated power source set

at 125 psi maximum. The power source must have a

safety relief valve set at 135 psi maximum.

19. THE TOOL SHOULD NOT BE OPERATED AT

THE MAXIMUM AIR PRESSURE.

The tool air-line should be connected to the power

source through an airline pressure Regulator and an

airline Filter. The air line Regulator should never be

set higher than 110 psi as marked on the tool. Lower

pressures may be used as recommended by the

manufacturer.

20. HAZARDOUS POWER SOURCES SHALL NOT

BE USED.

Hazardous power sources including, but not limited

to, Oxygen, Combustible gases, sources whose

pressure can exceed 200 psi if the pressure Regulator

fails, bottled gases, including air should never be used.