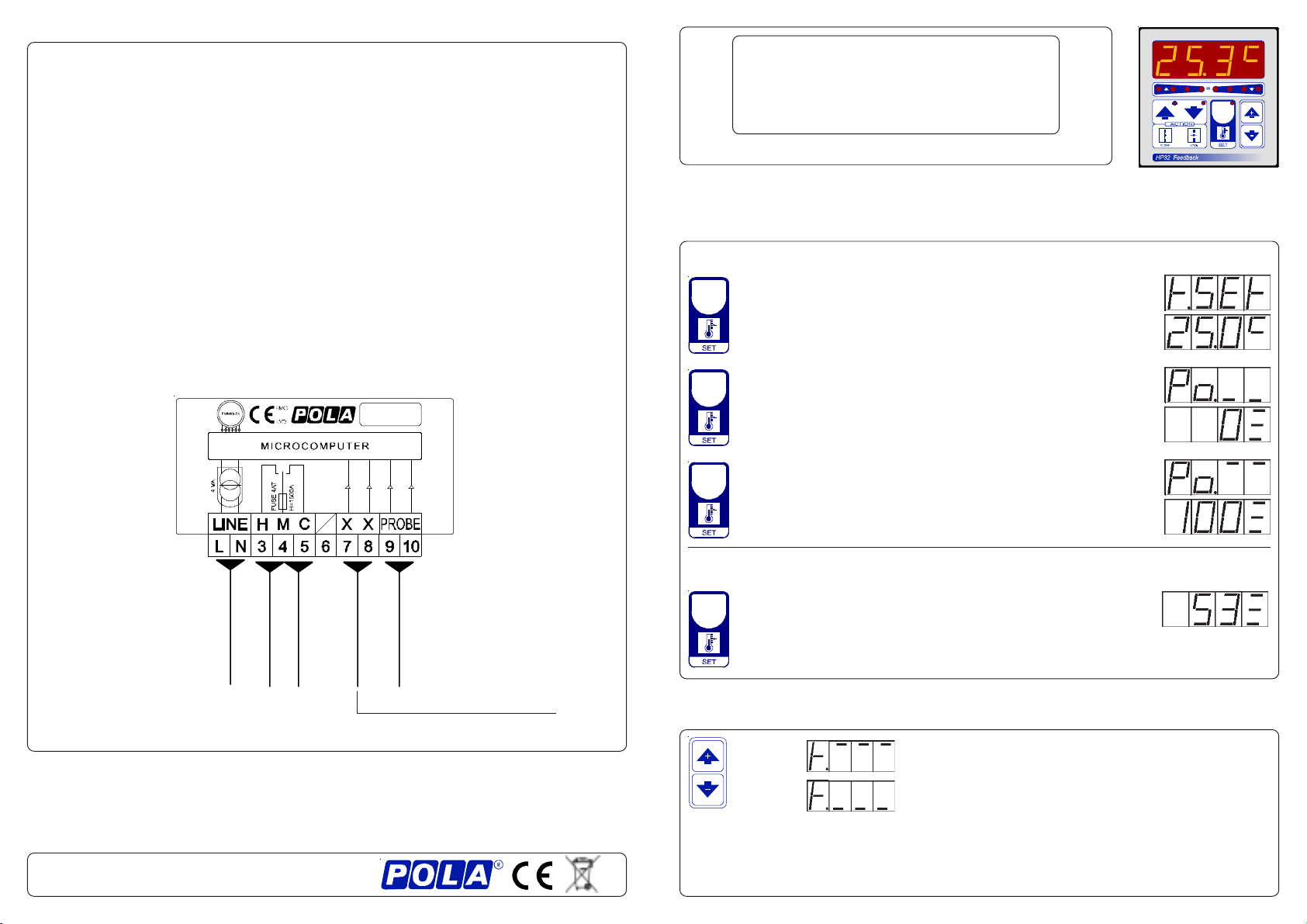

PRESET PROGRAMS (Bootstrap)

This processor is already programmed with the following (variable) settings.

To return to these settings at any time you may:

Power off the processor, press SET key and keep it pressed giving power on:

boot message will be displayed (release now SET key).

t.SEt=25.0° Po._ _= 0 Po.- -=100 .

The COSt values are shown in COSt Programming

*1) For more details see Operative Diagram.

*2) Reached SET temperature (SET key in Run Mode) flap position is that value (0is

fully closed).

*3) If swing occurs when searching for the position during flap operation (due to

mechanicalgearmotorhisteresis),itraisesthePcn.1settingvalueuntiliseliminated.

*4)Thatvalues canbeenteredinmanualorautomaticmodeareset byInitprocedure.

*5) tEnP =0 : °C Temperature range.

tEnP =1 : °F Temperature range.

*6) You can correct the readings on the various sensors (+ or -).

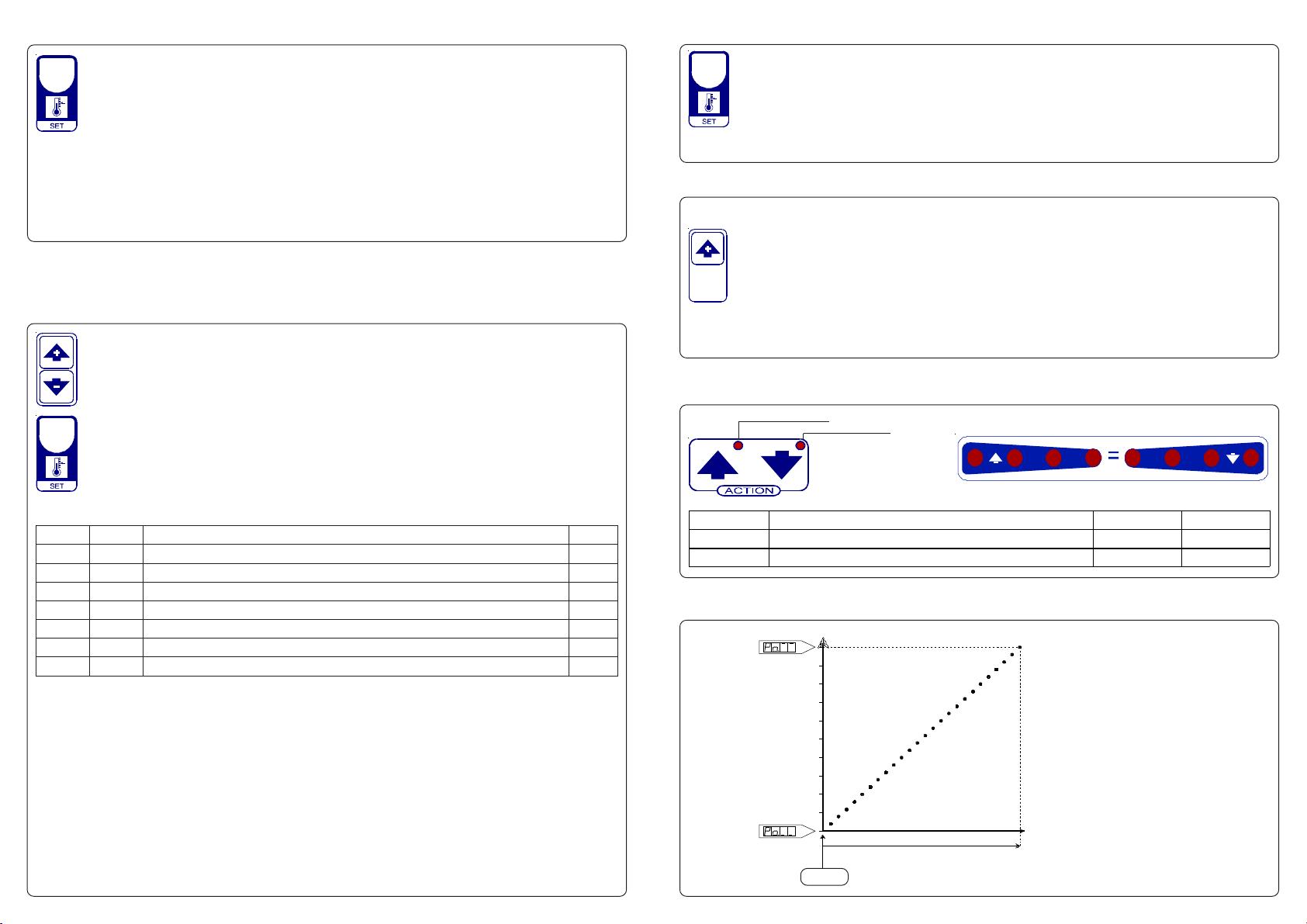

COSt PROGRAMMING (System constants)

t.SEt. with Pct.1=0

100

90

80

70

60

50

40

30

20

10

0

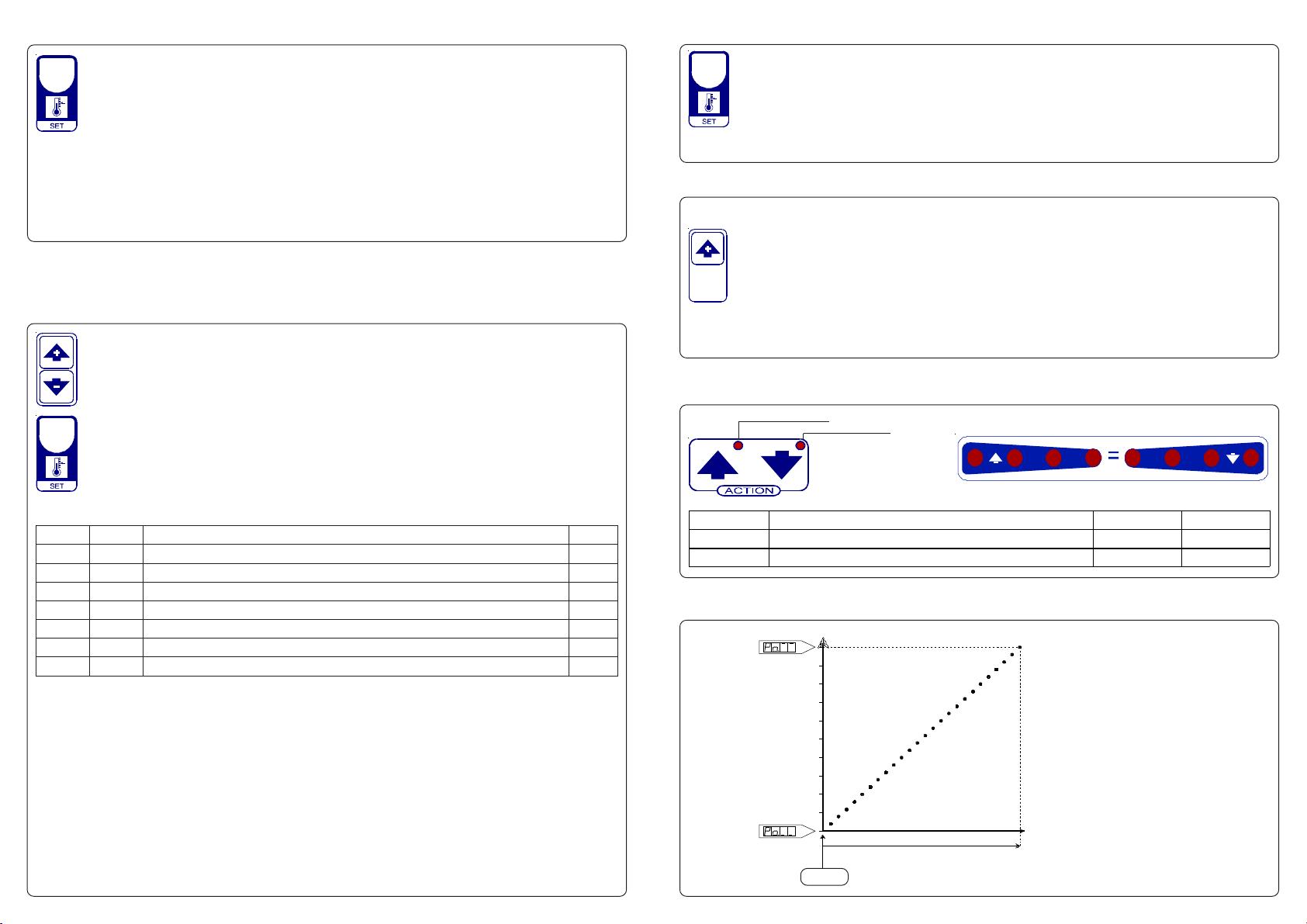

OPERATIVE DIAGRAM

ProP °Ambient temperature

% Opening Flap

FLAP POTENTIOMETER INITILIZATION PROCEDURE (Init)

Connectthepotentiometerofanyvalue(max10Kohm,recommended1Kohm).

It must be applied to the flap motor.

Having done this, proceed as follows to record the potentiometer values.

Press SET key for at least 5 seconds: when Init message will be displayed for

more than one second release SET key. HP32 closed the flap (light CLOSE

flashes) and the potentiometer resistance value is displayed.

Whentheflaphavecompletelyclosed,pressSETtorecordthevalue:atthispoint HP32

openstheflap(lightOPENflashes)andthepotentiometerresistancevalueisdisplayed.

When the flap have completely opened, press SET to record the value.

HP32 then returns automatically to the Run mode.

.sseM eulaV gninaeM etoN

PorP °0.4 egnarlanoitroporPC° 1*

1.tcP 0TESotpalfnoitisoP% 2*

1.ncP 5egnarlartueN% 3*

LC.oP 0noitisopdesolcpalfnirotsiserretemoitnetoP 4*

PO.oP 9999 noitisopnepopalfnirotsiserretemoitnetoP 4*

PnEt 1= noitatneserpererutarepmeT 5*

Et.dA °0.0 )-ro+(noitcerrocerutarepmetrosnesC° 6*

These settings refer to the operation mode of the system and must be made on

initial startup. Press - / + at the same time for at least one second: the message

C.O.S.t. will be displayed.

Press than repeatedly SET until the message regarding the chosen variable is

displayed (see table below) : value of variable and message will be displayed.

Press + or - to set a new value and then press SET to confirm.

The next system constant will then appear.

You can press SET for at least 2 seconds to exit and return to the Run Mode.

In some start-up conditions may be useful to work in "manual" mode:

Powerofftheprocessor,press + keyandkeepitpressedgivingpoweron:HAnd

message will be displayed (release now + key).

Push + until is displayed number required to be handed (see table) and push

SET for activing relay.

Pushing again + for increase relay number previous relay is disactivated.

You can press SET key for a least two seconds to escape and return to the

Run Mode.

MANUAL MODE

STATUS INDICATION LAMPS

Lamp. Meaning N°Relay Contatcts

CLOSE Close (Heat) On 1 3-4

OPEN Open (Cool) On 2 4-5

ON OPEN (COOL)

ON CLOSE (HEAT)

Swinging Ambient / Set temperature (t.SEt) indicator