4

AU Telephone Helpline: 1300225960

Installation

Note: If the unit has not been

stored or moved in an upright

position, let it stand upright for

approximately 12 hours before

operation. If in doubt allow to

stand.

1. Remove the appliance from the packaging.

Make sure that all protective plastic film and

coatings are thoroughly removed from all

surfaces.

2. Maintain a distance of 20cm (7 inches)

between the unit and walls or other objects for

ventilation. NEVER LOCATE NEXT TO OR

NEAR A HEAT SOURCE.

Note: Before using the appliance

for the first time, clean the

shelves and interior with soapy

water.

Operation

Storing Food

To get the best results from your POLAR appliance,

follow these instructions:

• It is important that food entering the Blast

Chiller/Freezer does not exceed a temperature

of 90°C.

• It is recommended that metal containers /

trays are used as other materials such as

plastic or polystyrene containers will act as an

insulator and extend blast chilling times.

• Sufficient space must be left between products

in order to guarantee a sufficient flow of cold

air. Ensure product is not in contact with the

internal walls of the unit, and leave sufficient

gaps between trays.

• Never obstruct the inlet of the evaporator fans.

• Products that are more difficult to chill because

of their composition and size should be placed

in the centre of the unit.

• Blast chilling data refers to standard products

(low fat content) with a thickness below

50 mm: therefore avoid overlaying products

on trays or the insertion of pieces with a

much higher thickness, as this will lead to

an extension of blast chilling times. Always

distribute the product well on the trays and in

the case of thick pieces decrease the amount

to blast chill.

• Limit the number of times and the duration of

time the doors are opened.

• The chiller should be used for storage for short

periods only.

• When removing product that has undergone

blast chilling/shock freezing, always wear

gloves to protect the hands from cold burns.

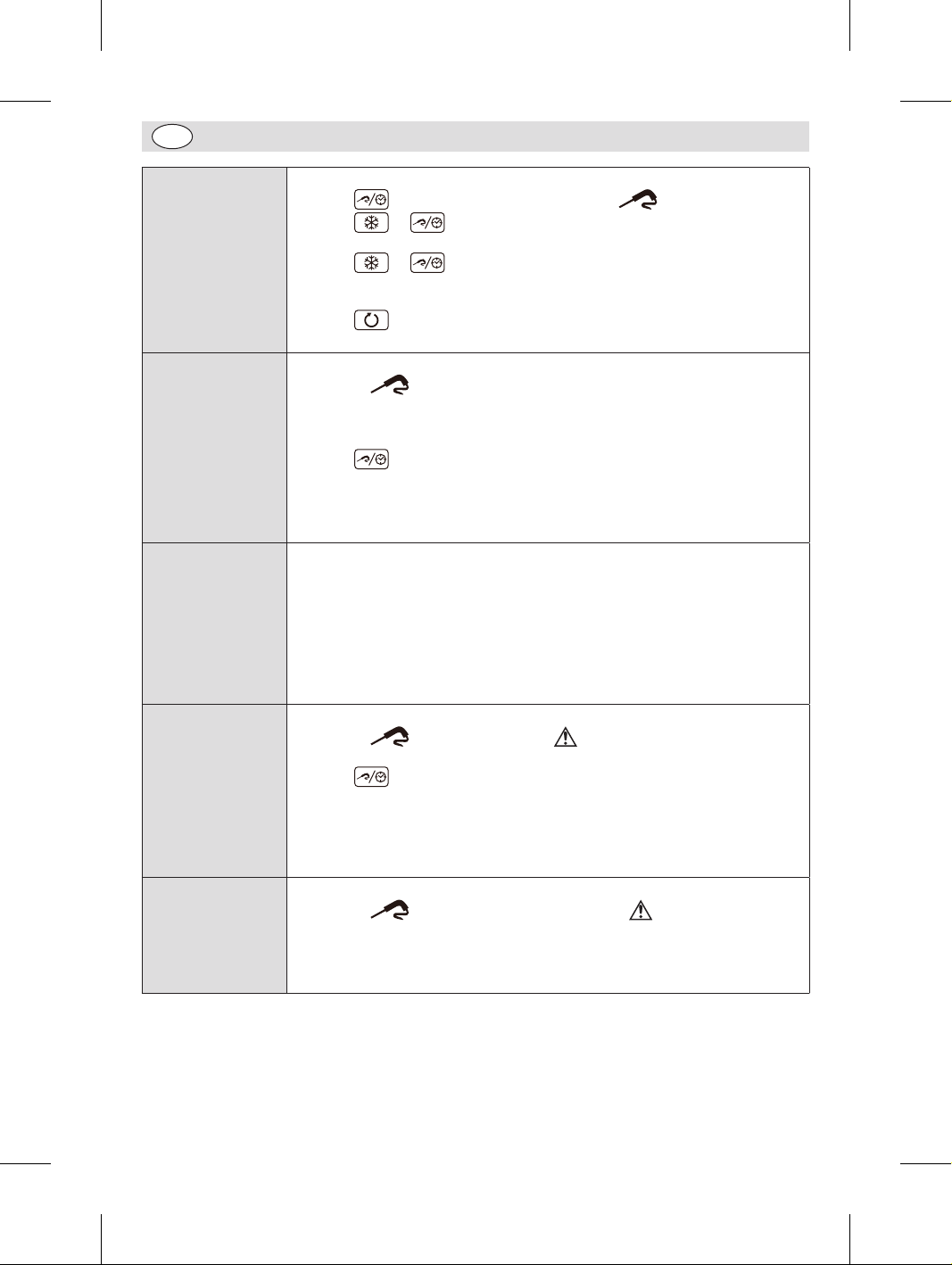

Introduction

The appliance has the following operational states:

On • The appliance is switched on and

an operating cycle is running

Standby • The appliance is switched on but

no operating cycle is running

Off • The appliance is not switched on

• If power is interrupted during a timed blast

chilling operation, when power is restored,

chilling will continue from the time point

at which the interruption occurred (with a

maximum error of 10 minutes).

• If power is interrupted during a set-

temperature blast chilling operation, when

power is restored, chilling will start again from

the beginning.

• If power is interrupted during a storage

operation, when power is restored the storage

operation will be reset.

• If power is interrupted while in “stand-by”

mode, when power is re- stored the device will

be in the same state.

Turn On

1. Ensure the power switch is set to [O] and turn

on at the socket.

2. Switch on the Power [I]. This will place the

unit in standby whilst waiting for the cycle to

be selected.

CK640-A_A5_v1_20190507.indb 4 2019/5/7 15:55