Polymaster ST3100 Installation guide

Septic Tank

1. Select site

• Contact relevant authorities

before digging to locate all

underground cables and pipes

• Determinethe best location of the

tank taking into account existing

underground services, excavation

required, locationof blackwater run and

heights into tank and outlet fall to drain.

• Is the tank excavationhole far enough

away not to impact on foundations

and adjoining structures? Where

no regulations exist the distance of

the excavationfrom any structure

should beaminimum of 2times

thedepth of the excavation.

• Consult with a Geotechnical Engineer

if you have any questions about

possibleinfluence of excavation

on surrounding structures

• Must not be installed where there is

apossibility of water table exceeding

half the height of the tank

2. Excavation

• Excavate hole according to

dimensions of tank

• Excavationslopes should be a

minimum of 30 degrees

• Hole depth should bea minimum of 1675

below finished pavement /lawn level

• Remove all loose soil from baseof hole,

and add 100mm of sand or crusher

dust and compact to a firm level pad.

• Be aware of thesafe working practice

for working in excavated holes.

• Hole dimensions at the base should

be a minimum of 200mm larger in

width and length of thetank.

Installation Guide

• ST3100

• ST4550

CHECKFIRST...

Read this manual thoroughly to ensure

all procedures are understood and

materials needed are available.

1800 062 064

polymaster.com.au

Innovative products

engineered with confidence

3. Positioning Tank

• Using the top lifting points for

stability, lift tank into place by use

of a backhoe or excavator.

• The Tank has 4 feet for stability but

extra chocking may be necessary

depending on conditions

• Using the access hole for a guide,

level tank in both directions

4. Backfilling

• Before commencing backfill, fill the tank

with water up to the half way mark.

• The backfill material around the tank

must be compacted inlayers not

exceeding 200mm.Use only hand

held vibrating plate compactors

in the compaction process.

• Use cohesionless material such as

sand, crusher dust, 6mm FCR etc. as a

as shown. The material should be a

minimum density of 18KN/m3 and

maximum density of 20KN/m3.

5. Final hookup

• Ensure all caps and overflows are sealed

prior to backfilling the excavation

and check all connections.

• Apply 20mm silicone bead around the

groovein the top of theaccess hole

and fasten lid down with tek screws.

• If ariser is to be used, fasten riser

in from the inside with silicone

and tek screws and thenfit lid.

HEALTH & SAFETY

taken to ensure the customer ’s health and safety. The following points need to be carefully considered:

• Useaqualified plumber/installer to install and fit-up tank.

• When lifting tank in to place use the appropriate lifting lugs onthe tank and lower evenly into

hole. Do not manhandletank in to place or try lifting manually as injury could occur.

• young children, personnel and animals, and could result in death by drowning.

• All Worksafe regulations and safe work procedures should be adhered to when

installing your septic tank. Never enter the tank at any timewithout adhering to all

guidelines and protocols of relevant confined space entry warnings and directions.

IMPORTANT

It is the responsibility of the owner to ensure proper installationand maintenance of the

underground tank. Polymaster will not beheld responsible for any loss, injury or death resulting

from a failure to observe all safety and installation requirements or safe working procedures.

PAGE 2 – Polymaster Septic TankInstallation Guide

100mm Sand

bedding layer

Indicative

excavation

line

Compact

in layers of

200mm.

Use free draining

granular material

Max density 20kN/m3

Min density 18kN/m3

of backfill

Finished pavement/lawn level

Care of your Septic system

Owners reference

Polymaster septic systems

Septic systems are ‘on site’ individual wastewater

systems that usethe soil to absorb and

naturally treat wastewater flows. They are

typically used where centralised sewerage

treatment is impractical or not available.

Aseptic system uses bacteria to break

down the waste and therefore it is important

that you do not usecleaning products

or dispose of any product down the

drainage system that will kill bacteria.

Items to watch out for are:

• Products that contain chlorine

or ammonia

• Fats and greases

• Non-degradables suchas

disposable nappies,sanitary

napkins,cat litter, plastics etc.

• Poisons like petrol,paint,

thinners, pesticides etc.

• Excessive food scraps

There is a range of biological cleaning

products that are madespecifically

for usewith septictank systems.

Odours

It is normal in thefirst few weeks of operation for

yourseptic tank to produce someodours which

after ashort time will disappearor be replaced

with a slight earthy smell. If there is much change

to your situation you may find you have used some

chemicals or have put a large amount of washing

through the laundry. If this is the case theunit will

correct itself in a few days; try to spread the

laundry evenly over the weekas much as possible.

Ground Maintenance

Septic systems have a network of drainage

pipes that allows the wastewater to seep into

the subsurface soil. The area over this ‘drainfield’

should beleft undisturbed with only amowed

grass cover. Divert excessive ground/stormwater

away from this area and be aware that roots from

nearby trees orshrubs may clog and damage

your drain lines. Do not allow anyone to drive

or park over any part of the drainage system.

Remember: less water used means less

water to be treated and disposed of.

Desludging your septic tank

Septic systems overtime will build up withan

excess of accumulated solids that should be

pumped out every 3-5 years. This depends

a lot on the volume that is put through the

tank so varies greatly on applications.

Make sure the tank is pumped out

by alicensed liquid waste contractor,

pleasesee the local council in your area

about any special EPA regulations.

in the tank to ensure tank does not

float up or become dislodged.Bacteria

levels in the tankwill restore once

wastewater enters the system again.

For more information about maintenance

or inspection of your Polymaster Septic

System contact the plumberwho

installed your tank or the local council.

Please Note: Never allow anyone at any time to enter the septic tank as it is

a confined space and once operating is an extreme health risk.

PAGE 3 – Polymaster Septic Tank Installation Guide

ACKNOWLEDGMENTANDRELEASE

The customer undertakes to install our underground tanks strictly to the manufacturer’s directions, recommendations and specifications

as contained in the Installation Manual accompanying the tank.

of thesetanks,the customeragrees that he/sheshall not hold the manufacturer (Polymaster) liable and acknowledges and accepts that

the customeris wholly liable for such loss and damage and releases the manufacturer from any liability.

Thank you

Thank you for purchasing a Polymaster Septic Tank. The purpose of a septictank is to

provide a complete septic tank system which complies to Australian Standards, and

gives you guaranteed performance.

Stringent testing

Some of the stringent testing and standards we have complied to are listed below:

• Complies with AS/NZS1546.1:2008 for the constructionof septic tanks.

• Tanks have been designed using engineering design

methods including finite element analysis.

• By following the installation requirements. You will find this

tank will give you many years of troublefree service.

Warranty details

Polymaster septic tanks come with aseven year manufacturer’s warranty. This is to keep

meets with accreditation guidelines guaranteeing aservice life of 15 years.

To validate your warranty all installationinstructions must be strictly adhered to. When

outlined below.

Please visit warranty.polymaster.com.au to submit

your warranty on this product.

•Alternatively, if you do not have access to the online

warranty page, contact us on 1800 062 064

•Please activate your warranty online at

warranty.polymaster.com.au

Activate your warranty

Like us on

Enter Our ‘my tank’ Photo Competition

Coles Group & Myer Gift Card

$100

We would love to hear about your experience with Polymaster...

Please share your comments on our facebook page!

facebook.com/polymastergroupaust

to WIN a $100 Coles Myer Gift Card! Drawn monthly.

2 Ways to Enter :

Post a photo of your new tank/s on Facebook.

Type ‘ @Polymaster Group ’ (select our page)

1.

•Alternatively, if you do not have access to the online

warranty page, contact us on 1800 062 064

•Please activate your warranty online at

warranty.polymaster.com.au

Activate your warranty

Like us on

Enter Our ‘my tank’ Photo Competition

Coles Group & Myer Gift Card

$100

We would love to hear about your experience with Polymaster...

Please share your comments on our facebook page!

facebook.com/polymastergroupaust

to WIN a $100 Coles Myer Gift Card! Drawn monthly.

2 Ways to Enter :

Post a photo of your new tank/s on Facebook.

Type ‘ @Polymaster Group ’ (select our page)

and hashtag #mypolymastertank

1.

We would love to hearabout your experience with Polymaster...

Please share your comments on our facebook page!

facebook.com/polymastergroupaust

1800062064 | polymaster.com.au

This manual suits for next models

1

Popular Water Heater manuals by other brands

State Water Heaters

State Water Heaters SCE 80-115 Installation, user and service manual

A.O. Smith

A.O. Smith BTH 120 - 250 Installation & operation instruction

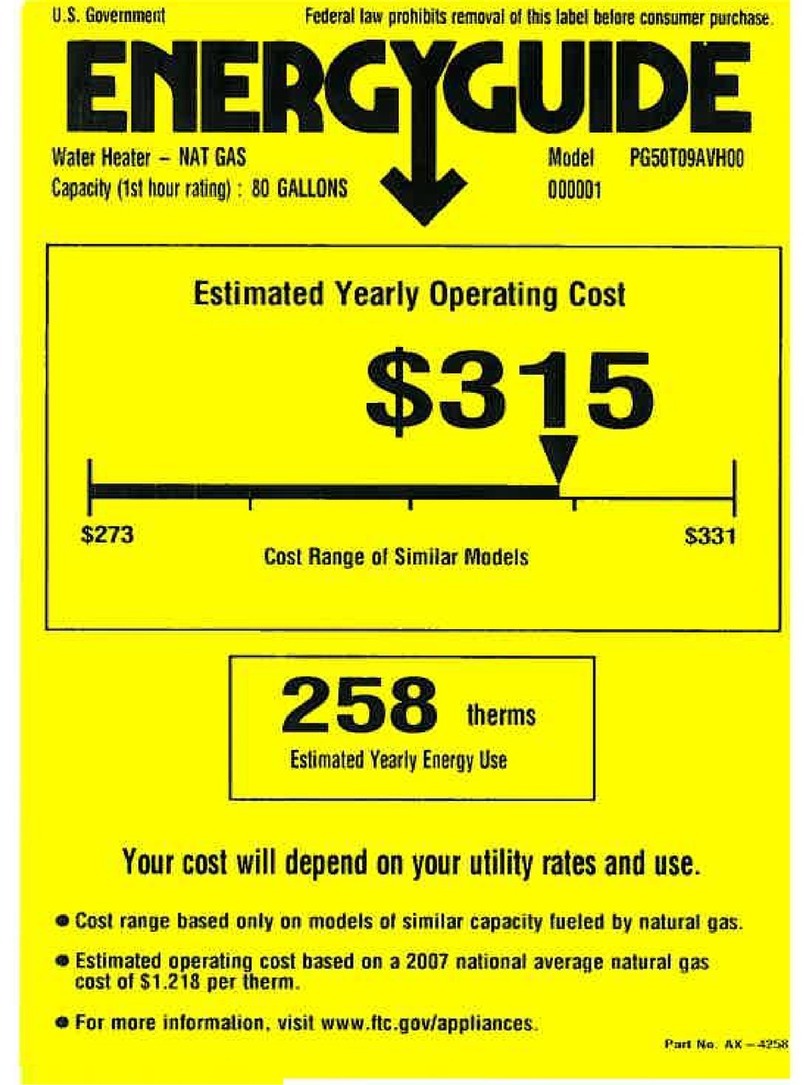

GE

GE PG50T09AVH Energy guide

E.C.A.

E.C.A. 22 HS -11 Installation and user's operating instructions

Mi-T-M

Mi-T-M HOM-SERIES operating instructions

Raypak

Raypak B0200 owner's guide

Nibe

Nibe AP-WH7 operating manual

Giant

Giant UG30-32MF1-C2U owner's manual

Rheem

Rheem 60 Gallon Use & care manual

flowair

flowair LEO FL 30 Technical documentation operation manual

Viessmann

Viessmann Vitosol 100 Start up & operation manual

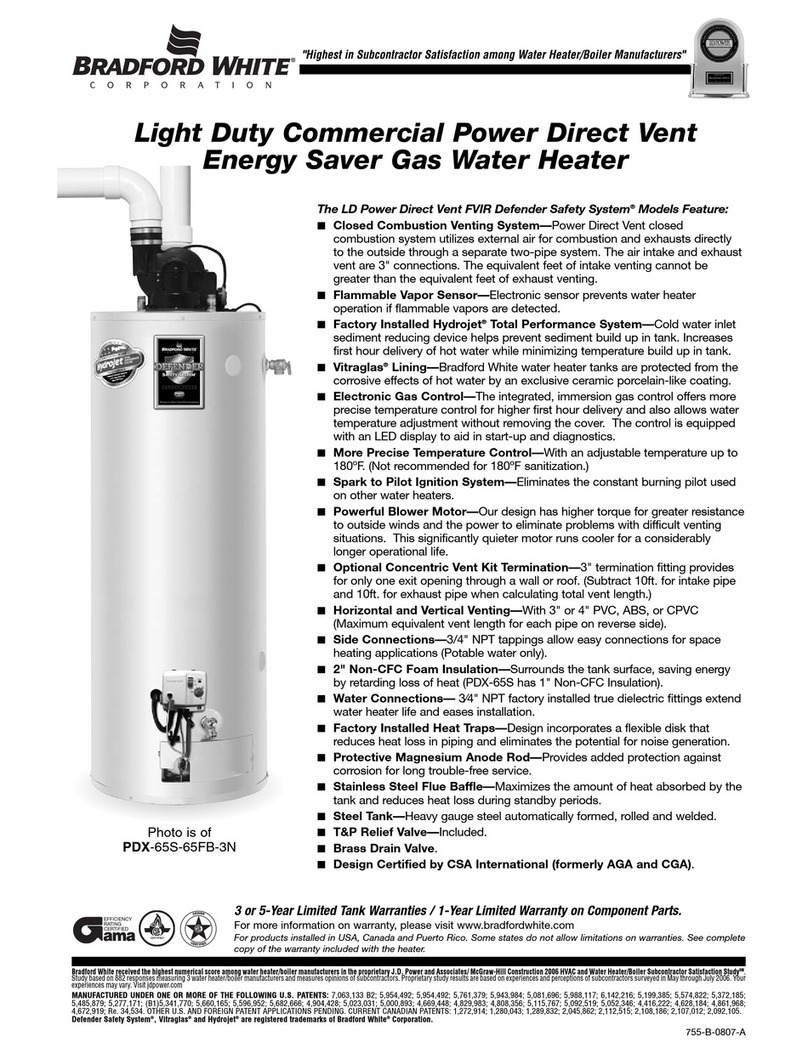

Bradford White

Bradford White 238-44219-00J Installation and operating instruction manual