Content

2. General ............................................................................................................ 3

2.1 Service address................................................................................................ 3

2.2 General information .......................................................................................... 3

2.3 Labelling ........................................................................................................... 4

2.4 Guarantee......................................................................................................... 5

2.5 Technical data .................................................................................................. 5

3. Safety............................................................................................................... 6

3.1 Marking of details in the operation manual ...................................................... 6

3.2 Safety instructions for hose pumps in hazardous locations .............................. 7

3.3 Intended use..................................................................................................... 7

3.4 Qualification and training of personnel.............................................................. 8

3.5 Dangers in case of non-observance of the safety instructions.......................... 8

3.6 Safety-conscious working................................................................................. 9

3.7 Safety instructions for the operator/user........................................................... 9

3.8 Safety instructions for maintenance / inspection / assembly............................. 9

3.9 Unauthorized modifications or use of unoriginal parts .................................... 10

3.10 Unauthorized operating methods .................................................................. 10

4. Transport, storage and disposal ................................................................. 11

4.1 Transport ........................................................................................................ 11

4.2 Storage........................................................................................................... 11

4.3 Disposal.......................................................................................................... 11

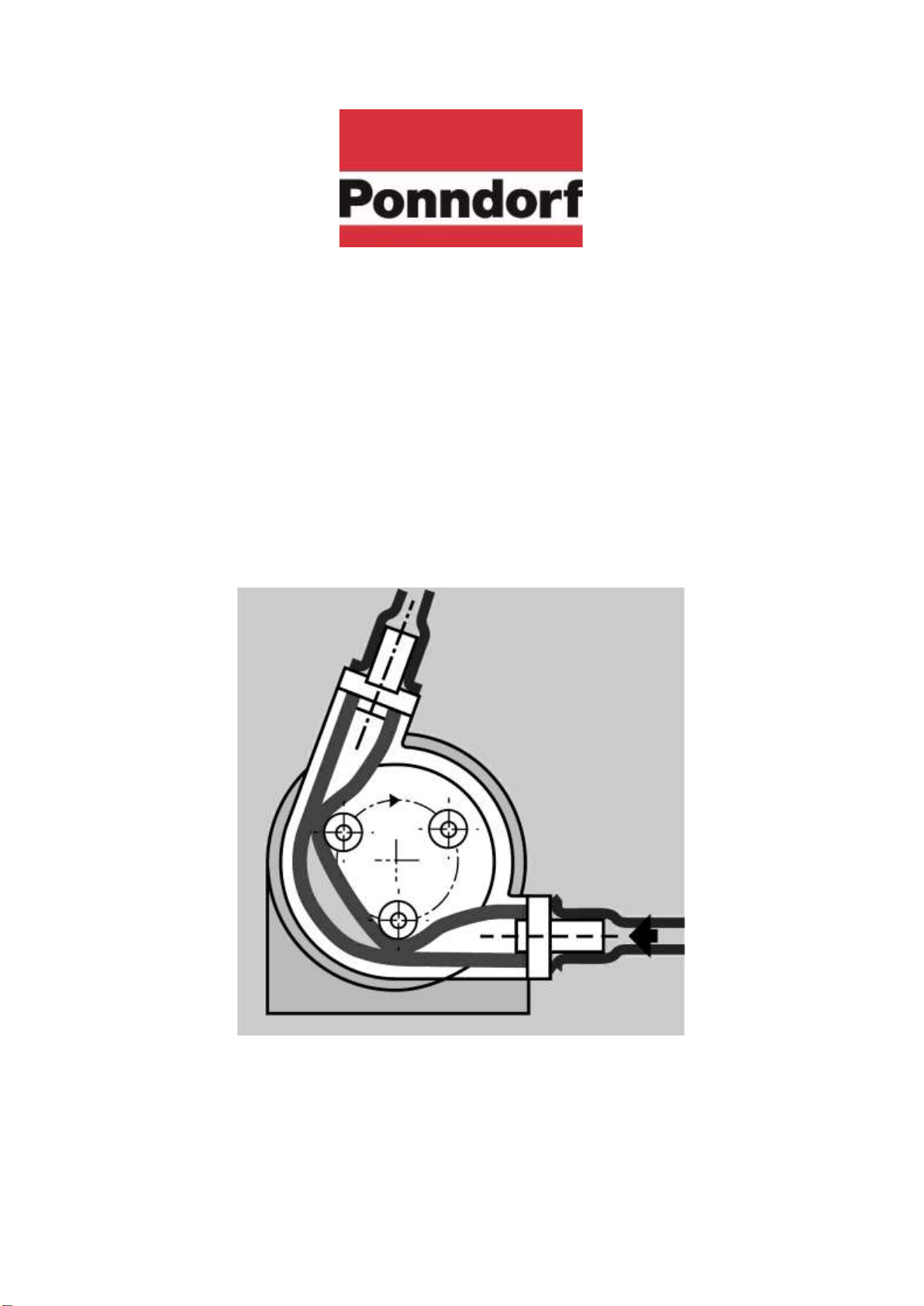

5. Description of pump and accessories........................................................ 12

5.1 Detector for hose leakages............................................................................. 13

5.2Diagram of the leakage detector for operating the pumps in non-hazardous

locations (art.-no. 93-000-055)........................................................................ 14

5.3 Diagram of the leakage detector for operating the pumps in non-hazardous

locations (art.-no. 93-000-009)........................................................................ 15