General

Make sure that the fixed ground wire in the building is securely connected to earth.

Wiring tasks should be carried out by qualified electricians only, in addition, they should check

the safety conditions of power utilization, for example, check if the cable capacity is adequate,

and check if the power cable is damaged.

Home users must not install, repair or relocate the unit.

Improper treatment might lead to the accidents e.g. personal injury caused by fire, electrical

shock or unit's falling-off, and water leakage in the machine. Please contact professionals for

repair.

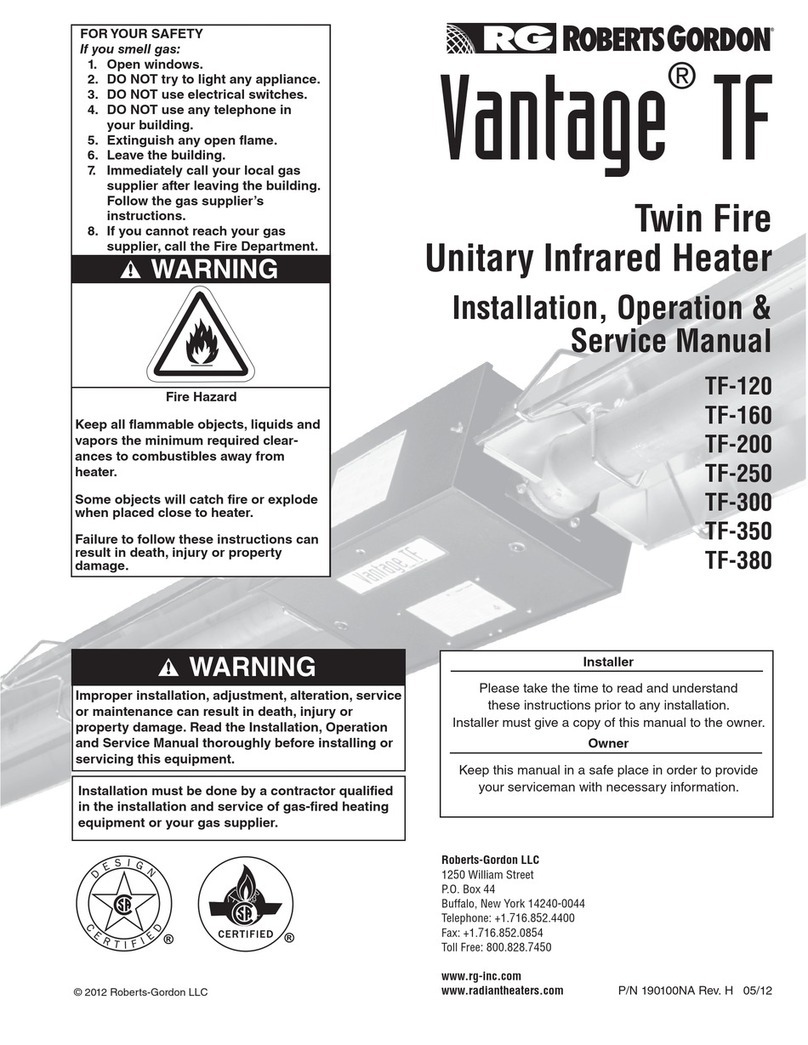

The unit shall not be installed at a spot with potential hazard of leakage of inflammable gas.

In case the leaked gas is congregated around the machine, there might be the risk of explosion.

Make sure that the foundation of installation is stable.

If the foundation is unstable, the outdoor unit may drop and cause a casualty.

Make sure that the electric leakage protection switch is fixed.

If no electric leakage protection switch is fixed at the beginning of the electric supply, it maybe

cause electric shocks or fires.

If any abnormity occurs in the unit (such as burned smell inside the unit), cut off the power

Supply immediately, and contact professionals for repair.

Please follow the instruction below when cleaning the unit

a. Before cleaning, cut off the electric supply of the unit firstly to avoid injuries caused by fan

in operation.

B. Do not rinse the unit by water because the rinsed unit may cause electric shock.

Make sure to cut off the electric supply before maintaining the unit.

Please do not insert fingers or sticks into air outlet or air inlet.

The machine must be transported and stored vertically

Transport and storage

.

!

!

!

!

!

!

!

!

!

!

!

Note!

It is required to read the Safety precautions in details before

operation. The precautions listed below are all-important for

safety. Please follow the instructions strictly.

Safety Precautions

3ENGLISH